Micro-Mold Demonstration Highlights Collaboration

Mold Craft Inc. demonstrates micro-injection molding NPE2018 with a Wittmann Battenfeld press and a Sodick vertical molding machine.

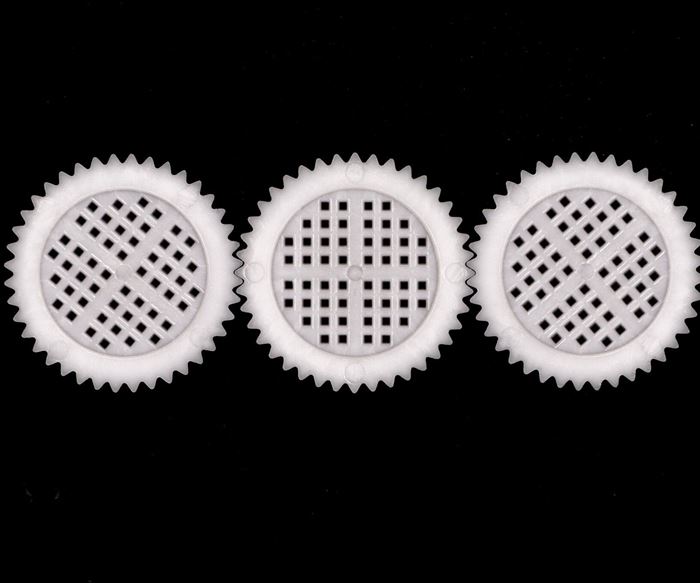

Mold Craft Inc. demonstrates micro-molding of a 100-µm filter screen with POK resin using the Wittmann Battenfeld MicroPower 15-t press in booth W4207. Mold Craft also has personnel in Sodick’s booth (W782), where it molds PEEK 100-µm filter screen micro-parts in the LP20VRE vertical molding machine, which has a two-stage plunger system.

Mold Craft has a typeable .pdf checklist for DFM criteria available at NPE2018 to help visitors describe their perfect micro-mold. If visitors return the completed document, Mold Craft responds with information and advice on moldability and manufacturing. Its complete design package includes models, assembly views, bill of materials and prints with fully documented dimensions and tolerances for the micro-mold.

Mold Craft realizes that certain areas of a mold are going to wear faster than other areas so Mold Craft designs its molds to make those areas replaceable. Those areas include gates, thin steel, shutoffs and core pins. Mold Craft says that it designs molds this way to save customers time and money over the life of the mold.

Related Content

-

Scaling New Heights With Vertical Integration

Eden Manufacturing was founded on a vision of vertical integration, adding advanced injection molding capabilities to a base of precision moldmaking and more recently bringing Swiss-type machining capabilities in-house.

-

How to Achieve Simulation Success, Part 2: Material Characterization

Depending on whether or not your chosen material is in the simulation database — and sometimes even if it is — analysts will have some important choices to make and factors to be aware of. Learn them here.

-

Where and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.