New Class of Photoplastics for SLA 3D Printing of Durable Prototypes, Tooling, Functional End-Use Parts

Nexa3D and Henkel have announced availability of three functional photopolymers with extended UV weathering stability.

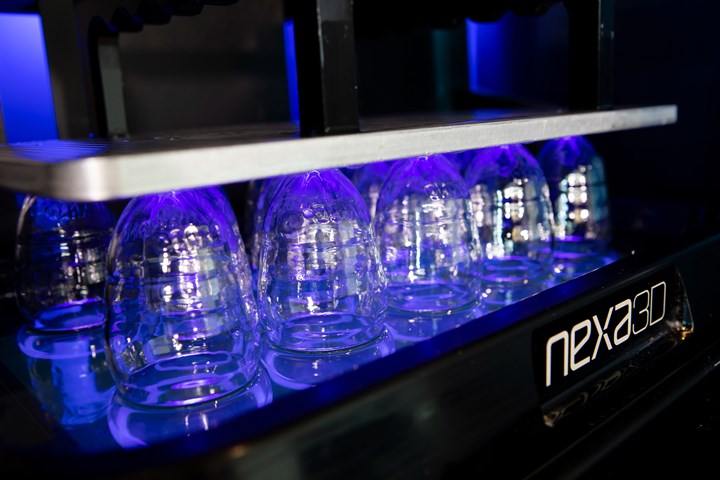

The availability of three new functional polymers, said to represent a new class of photoplastics and designed for durable prototype, production tools and functional end-use parts with extended UV weathering stability have been announced by Nexa3D, Ventura, Calif., the maker of ultra-fast SLA production 3D printers and Germany’s Henkel. Available through Nexa3D’s globally expanding channels, the three new performance photopolymers represent the company’s further collaboration with Henkel which leverages their combined capabilities to fast-track additive manufacturing towards mass production of functional parts across multiple industries, leveraging productivity advantages of its ultrafast NXE 400 3D printer.

The ultrafast NXE 400 manufacturing process offers multiple possibilities for greater design agility, supply chain resiliency and ultrafast implementation at every phase of the product lifecycle. Combining Nexa3D’s productivity with Henkel’s rapidly expanding portfolio of functional polymers, makes it possible for customers to manufacture a wider range of parts such as housings, enclosures, pipes, packaging products, footwear components and production tooling for greater performance and functionality. The three photoplastic materials are:

▪ xPP405-Black is a tough semi-rigid material with high-strength engineering plastic delivering good impact resistance with performance similar to unfilled propylene. This photoplastic boasts a modulus like PP, an impressive 130% tensile elongation at failure, and excellent UV weathering stability as characterized by ASTM G154 testing. It reportedly delivers an attractive industrial black finish and is ideal for a wide variety of design, engineering and manufacturing of end use parts for piping, consumer and industrial applications, including large housings and enclosures and sheet metal forming dies.

▪ xPP405-Clear combines clarity, toughness and impact strength with good heat deflection temperature between 50 C /122 F to 60 C/140 F. This photoplastic boasts a modulus like PP, 130% tensile elongation at failure, and exceptional UV weathering stability as characterized by ASTM G154 testing. Grade xPP405-Clear can be finished for excellent clarity and is perfect for a wide range of design, engineering and manufacturing of end use parts including packaging, bottling, piping and see-through elements such as transparent materials for light guiding applications and micro-fluidics as well as lighting applications.

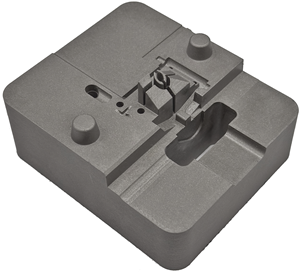

▪ xPEEK147-Black is a tough material with a good surface finish, and a strong dimensional stability featuring high-heat deflection temperature. Reportedly, it is an ideal material for production tooling, molding applications and a variety of functional end use parts including automotive underhood applications. This bioplastic exhibits higher temperature resistance of up to 230 C/446 F with very high stiffness and is shown to be thermally stable for long periods with good solvent resistance and dimensional stability.

Said Hankel’s head of innovation for 3D Printing Ken Kisner,“We are pleased to further expand our partnership with Nexa3D as Loctite’s portfolio of photo-plastic and photo-elastic materials are well-matched for the higher throughput of the NXE400 3D printer. The Nexa3D team have continued to deliver robust 3D printing solutions, and together we look forward to continuing to deliver an expanded portfolio of production tools, materials, and the validated workflows that the industry requires to realize the full potential of additive production.

Said Nexa3D COO Kevin McAlea, “We believe that our rapidly expanding collaboration with Henkel, now spanning six Loctite materials, coupled with our demonstrated productivity gains achieved by our ultrafast NXE400 3D printer and up to 85% lower total cost of ownership, delivers higher productivity, better extended life functionality and exceptional economics. Both companies are committed to democratizing access to scalable additive polymer solutions empowering customers to own their supply chain throughout their entire product life cycle from design to production and aftermarket success.”

Related Content

Production Tool, Prototype Time

Mantle's metal 3D printing technology targeted toolmaking and injection molders and moldmakers are taking notice.

Read MoreDuPont Buys Medical Product Manufacturer Spectrum Plastics

Purchase price of $1.75 billion for leading supplier of extruded, molded, and 3D printed medical components.

Read More3D Printing of Injection Molds Flows in a New Direction

Hybrids of additive manufacturing and CNC machining can shorten tooling turnaround times.

Read MoreMake Every Shot Count: Mold Simulation Maximizes Functional Parts From Printed Tooling

If a printed tool only has a finite number of shots in it, why waste any of them on process development?

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More