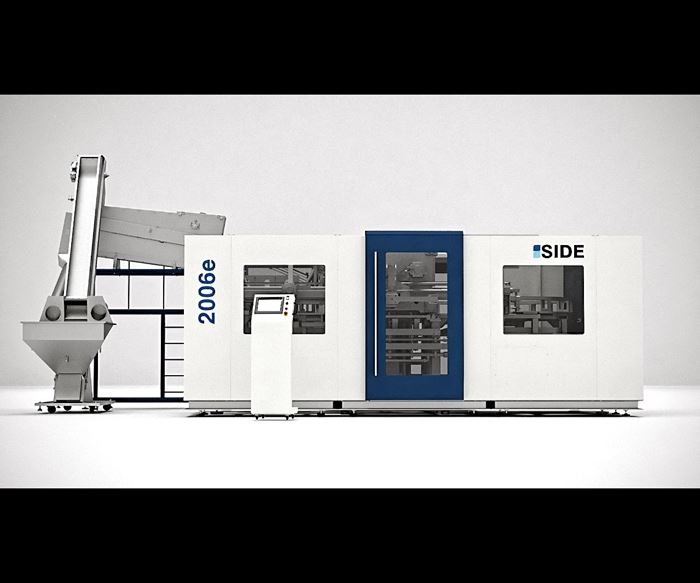

New PET Machines & Pinch-Handle Technology

SIDE presents a new generation of PET stretch-blow molding machines for products from 250 ml to 10 L.

SIDE S.A. of Spain presents its new generation of linear RSBM machines. They employ ABB variable-frequency drives, improved heating controls (Siemens), reduced mechanical movements to minimize wear, and easier access to the preform loader. These machines include the model 2006e, which takes up to six cavities for products from 250 ml to 3 L and output up to 10,000 bph. Model 2003eG is a two-cavity unit for up to 10 L containers and outputs from 2200 to 2600 bph.

SIDE will also feature its T-handle technology, which produces PET jugs with a pinched handle (up to 36 mm deep) through compression molding in the tool. It reportedly can make PET handleware competitive with HDPE, owing to higher throughputs with PET.

Related Content

-

For Extrusion and Injection-Blow Molders, Numerous Upgrades in Machines and Services

Uniloy is revising its machinery lines across the board and strengthening after-sales services in tooling maintenance, spare parts and tech service.

-

Breaking News From NPE2024

Here is a firsthand report of news in injection molding, extrusion, blow molding and recycling not previously covered.

-

Get Color Changes Right In Extrusion Blow Molding

Follow these best practices to minimize loss of time, material and labor during color changes in molding containers from bottles to jerrycans. The authors explore what this means for each step of the process, from raw-material infeed to handling and reprocessing tails and trim.