Non-Contact Control of Flat Dies, Adapters

More automation comes to flat die technology.

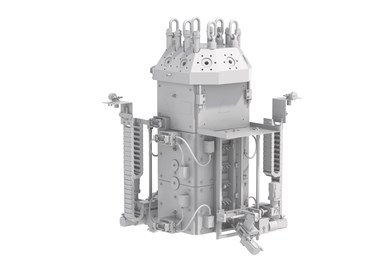

At K 2022, Reifenhäuser debuted its PAM (precise, automated, mechatronic) automation option for coextrusion adapters and slot dies in flat film, sheet production and extrusion coating. The system’s high level of automation reportedly makes the machine operator's work easier, thereby increasing line productivity and film quality. Energy consumption is also reduced, as manual adjustment bolts replace the conventional thermal expansion bolts.

With PAM, Reifenhauser says the coextrusion adapter and die can be precisely adjusted automatically and mechatronically from the line's operating panel. This is said to be significantly faster than conventional control by hand or expansion bolt automation, and enables faster start-up of production, higher output and improved overall equipment efficiency. Scrap and material usage are reportedly significantly reduced. Moreover, recipes that have been set once can be stored and recalled at any time so that they can therefore be reproduced exactly, even by inexperienced line operators.

Photos: Reifenhäuser

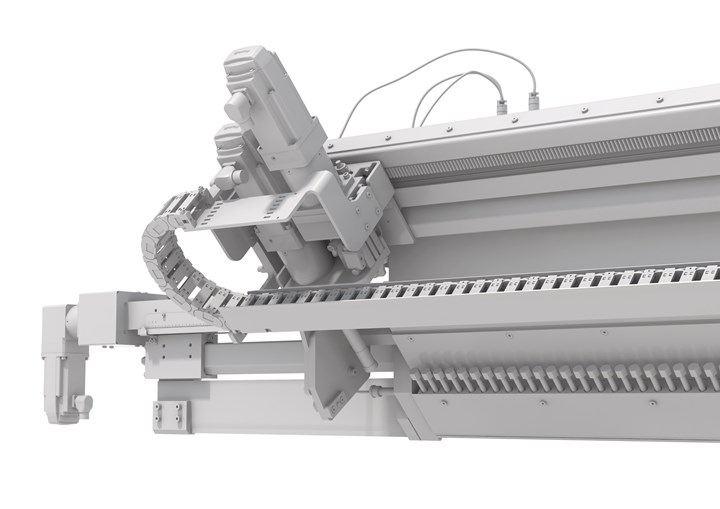

The technology relies on what looks like a belt-driven Allen wrench, which traverses the die and adapter to make bolt adjustments. More than one of these “traveling wrenches” can be deployed on the die depending on its width.

For extrusion adapters, Reifenhäuser’s Pro is reportedly the only system on the market that allows profiling of the individual layers while the line is running. Unlike conventional systems, elements located in the adapter do not have to be removed, processed and reinstalled in a time-consuming process. Instead, profilers can be flexibly controlled individually or together during operation via a central adjustment.

By adding the PAM option, the setting of the layer distribution is automated and adjustment simplified and optimized through integrated recipe management. This is especially for film processors that make products with many layers and have many product changes on their lines.

Related Content

-

Reduce Downtime and Scrap in the Blown Film Industry

The blown film sector now benefits from a tailored solution developed by Chem-Trend to preserve integrity of the bubble.

-

Part 2 Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Simulation can determine whether a die has regions of low shear rate and shear stress on the metal surface where the polymer would ultimately degrade, and can help processors design dies better suited for their projects.

-

How to Select the Right Tooling for Pipe Extrusion

In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due to a range of qualitative factors. Here’s some guidance to help you out.