PFAS-Free Process Aid Eases Switch for Extrusion Processors

Aimed at blown film, pipe, and wire and cable, two grades are reportedly compatible with other additives used in these processes.

Baerlocher USA’s Baerolub AID polymer processing aids (PPAs) is said to help extrusion processors smoothly transition from per- and polyfluoroalkyl substances (PFAS).

The new PPA targets blown film, pipe and wire & cable are free of PFAS and siloxanes, are billed as cost-competitive with existing and new PPA solutions, and are said to be compatible with other additives used in film, such as anti-block or slip agents. Baerolub AID PPAs deliver rapid melt fracture clearing for metallocene and Ziegler Natta LLDPE and HDPE, equaling or surpassing clearing times of traditional PPAs containing PFAS.

Because Baerolub AID PPAs are soluble in the polymer matrix, they provide better haze performance than insoluble PFAS-containing PPAs and excellent control of frost line height. Baerlocher USA’s new products can also reduce die build-up and extruder pressure. Because they are designed for maximum compliance with global food contact regulations, Baerolub AID PPAs are well suited for applications including PE films for food packaging and resins for potable water pipe.

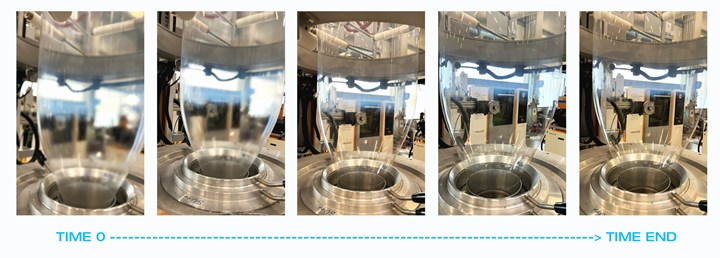

Baerolub AID PPAs are soluble in the polymer matrix, so they provide better haze performance than insoluble PFAS-containing PPAs and excellent control of frost line height. Photo Credit: Baerlocher

Says Dr. Robert Sherman, technical director for Baerlocher USA, “To give our customers a choice, we developed two grades of Baerolub AID. If you’re looking for the fastest time to clear the melt fracture in metallocene LLDPE, consider Baerolub AID 2201. In certain conditions, you may wish to select Baerolub AID 2202, which provides excellent melt clearing times compared to traditional PPAs.”

Baerolub AID products are available as neat additives (pastilles, rods, granules and powders), custom blends and in masterbatch form. Baerlocher also offers customers regulatory expertise and support for lab and technical screening, blown film testing and preparation for production trials.

Related Content

-

How Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

-

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so the barrel appears to be turning clockwise around a stationary screw.

-

How Screw Design Can Boost Output of Single-Screw Extruders

Optimizing screw design for a lower discharge temperature has been shown to significantly increase output rate.