Remote Service Added to Machine Line

Boy says its Smart Remote Service establishes a connection between its service personnel and its molding machines via “an integrated gateway.”

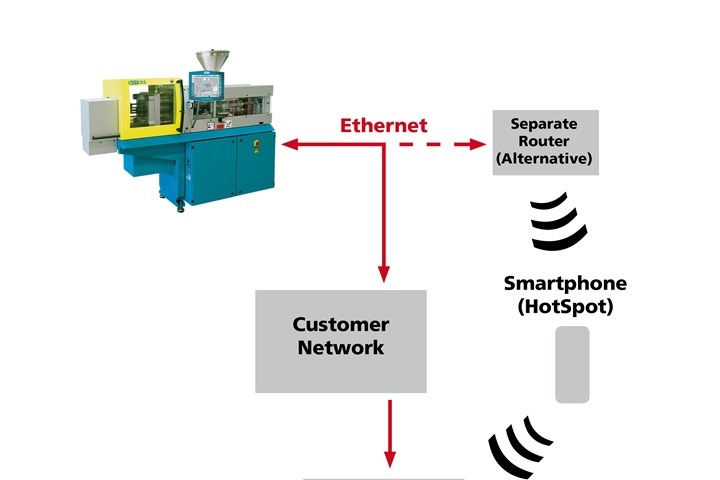

Instead of a service technicians identifying and fixing machine problems on site, Boy Machines says its Smart Remote Service can establish a connection with the press remotely. An internet connection is required, via the customer network or a hotspot; and while in the past the service technician’s laptop was required as an access point to gain remote access to the control, this is now achieved via a remote access integrated in the control. If there is no internet connection available at the machine’s location, a router can be used to access the internet via a smartphone’s hotspot.

Boy says technicians can set up a connection to the desired machine via a central screen so that the machine or system visualization can be operated via VNC. With this, the technician can perform software updates, debugging and maintenance as if directly on site.

With the Boy’s Smart Remote Service a range of remote maintenance options are available. The new online Smart Remote Service (SRS) tool can be used together with the interface package for all Procan Alpha 4 controls. Boy injection molding machines with older control versions cannot be retrofitted.

Boy Machines Smart Remote Service can establish a connection with a press remotely.

Related Content

-

Open Automation Enables Flexibility in Chemical Recycling

Software-defined equipment control systems can be duplicated, transferred and scaled with ease.

-

Adding Remote Service Functions for PET Bottle Blowing

KHS has added features to its internet machine communications portal for PET stretch-blow molding.

-

Four Industry 4.0 Tech Adoption Insights from Indiana Plastics Manufacturers

As more plastics manufacturers step into the Fourth Industrial Revolution, insights have emerged about how best to approach the digital transformation journey.