“Smart Nanocomposites” for Vehicle, Wearable Electronics and Buildings

OCSiAl’s graphene nanotubes combined with a TPU to fabricate nanocomposite sheets that can harvest electrical energy from sources of waste heat.

Easy-to-process, self-supporting and flexible nonwoven nanocomposite sheets that demonstrate excellent thermoelectric properties and good mechanical robustness have been developed using graphene nanotubes from the largest global manufacturer of graphene nanotubes OCSiAl. Potetential applications include sensors for vehicles, wearable electronics and buildings. A recent paper in ACS Applied Nano Materials described how researchers combined a TPU with OCSiAl’s graphene nanotubes to fabricate a nanocomposite material capable of harvesting electrical energy from sources of waste heat.

Thanks to their high aspect ratio and specific surface area, graphene nanotubes provide TPU with electrical conductivity, making it possible to achieve high thermoelectrical performance while maintaining or improving mechanical properties. “Stiffness, strength, and tensile toughness were improved by 7, 25, and 250 times compared to buckypapers, respectively. Nanocomposite sheet shows low electrical resistivity of 7.5*10-3 Ohm×cm, high Young’s modulus of 1.8 GPa, failure strength of 80 MPa, and elongation at break of 41%,” according to Beate Krause, group leader, Leibniz-Institut für Polymerforschung Dresden e. V.

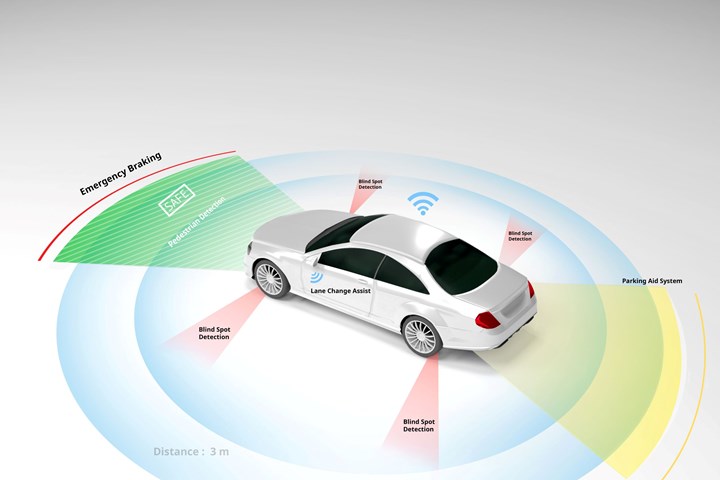

Based on expensive or corrosion-vulnerable materials which are rigid and often contain toxic elements, conventional thermoelectric generators (TEGs) currently have only low effectiveness and a relatively large size and weight. The potential to convert waste heat or solar energy into useful electrical power has emerged as an opportunity for more sustainable energy management. For example, one-third of a vehicle’s energy dissipates as waste heat in exhaust gases, and vehicles now contain more electronic devices requiring electrical energy. Similarly, lightweight wearable sensors for health and environmental monitoring are also becoming increasingly demanding. Graphene nanotubes present an opportunity to replace current TEG materials with more environmentally friendly ones. The sensors powered by such TEGs could act as a “smart skin” for vehicles and buildings, providing sensoring capabilities to monitor performance and prevent potential issues before they lead to breakdowns, ensuring optimal operational efficiency. In aircraft, no-https://ocsial.com/wire nanocomposites could serve as stand-alone sensors for monitoring deicing systems, eliminating the need for an extensive network of electrical cables.

Related Content

-

Masterbatches Reduce Gloss in PLA and PETG 3D Printed Products

Insight Polymers & Compounding’s two low-gloss additive masterbatches shown to boost appearance of 3D printed objects.

-

Additives Boast Sustainability Without Sacrificing Performance

Sustainability continues to dominate new additives technology, but upping performance is also evident. Most of the new additives have been targeted to commodity resins and particularly polyolefins.

-

Compatibilizer for Nylon/ABS Alloys

CAI Performance Additives’ ST-AN3230 has shown to improve both compatibility and performance of nylon/ABS alloys.