System Spots Surface Defects in Films

Detects gels, black specs, holes and other defects.

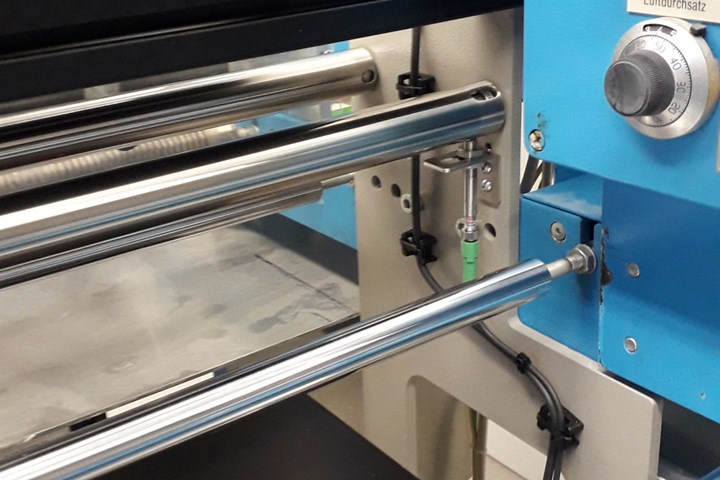

Optical Control Systems’ External Film Surface Analyser (FSA100EXT) is an optoelectronic laboratory inspection system for polymer films that can detect gels, holes, black specks, etc. The unit can be used with the supplier’s own lab extrusion lines or with lab lines furnished by others. The FSA100EXT comes with a customized frame with state-of-the-art camera technology, allowing it to accomodate the overall design of the existing line.

The advanced V2 camera technology consists of a high-resolution dual-line CMOS camera and a user-specific high-performance LED. This combination enables defect detection in transparent, opaque and colored polymer films. In the FSA100 software, the measurement results are analyzed according to customer-specific specifications and the defects are classified, which provides information about the film quality.

Related Content

-

Measuring Technology Specialist Pixargus Acquired by CiTex Group

A global player in optical inline quality control, Pixargus is intensifying presence in U.S. & Asia under CiTex umbrella.

-

Using a Melt Flow Indexer to Test Your Pressure Transducer

The MFI tester enables collection of meaningful pressure data in transducers in a relatively short time, providing realistic measures of the response time of a pressure transducer. This information is critical in the interpretation of pressure data measured in an extrusion process.

-

Inline Inspection System for Wood Plastic Composites

Pixargus’ ProfilControl 7 DX WoodPlasticComposites measure all dimensions and geometrics, including deep grooves.