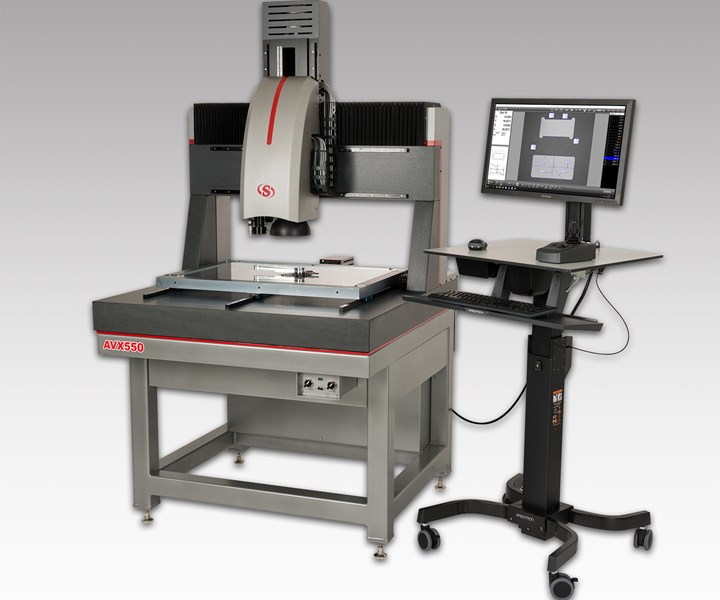

Testing: Large-Format Multi-Sensor Vision System

Starrett’s AVX550 large-format vision system boasts best features of vision and touch-probe inspection

A versatile large-format, multi-sensor vision system has been introduced by the L.S. Starrett Company, Athol, Mass. The AVX550 system is equipped with dual optical systems and touch-probe capability to measure parts with a diverse range of feature sizes and geometries. The large-format system can be equipped with two cameras and lenses to be used sequentially in the same program along with touch-probe options, reportedly making this system one of the most versatile multi-sensor platforms currently available. It also has a granite base and bridge design to ensure accuracy, durability and stability. Using a single system, production parts can be examined on the shop floor or in the QC lab on macro and micro levels, the company says.

With its dual optical systems, the AVX550 can measure a broad range of features. The primary zoom lens enables small intricate features to be inspected with high precision and resolution to 2 microns. A secondary large-field-of-view camera is equipped with a lens that can inspect large areas of a part, or an entire part. A broad range of zoom options eliminates the need to change lenses or to recalibrate the system. Throughput is said to be further enhanced with fast platform travel speeds and dual collimated profile lights which are essential to the effectiveness of the dual optical systems.

The M3 software package from MetLogix accommodates a mouse as well as a touchscreen monitor. Auto part recognition enables creating a part-measurement program that comprises the desired features for inspection, which can automatically be saved in the system or to a network. Programmable light-output options can be built into the program as defined steps, and can be included in the part recognition program. Once the program is created, placing that part within the camera’s field of view allows the saved program to initiate and run the inspection. A “Superimage” function allows piecing together multiple camera frames in order to view a large part as one single image. A Renishaw Touch Probe may also be utilized for quick acquisition of discreet points along a part’s profile and 3D geometry mapping.

The Starrett AVX550 Multi-Sensor System has several options for lens configurations. For inspection of small, intricate areas, a powerful 12:1 zoom optics lens is equipped with a 26x to 310x magnification range for precise resolution. The otherlens comes with fixed magnification options of 0.14x, 0.3x, 0.5x, 0.8x, 1.0x 2.0x and 4.0x. Besides the standard X, Y and Z axes, systems can be equipped with Q-axis rotary positioners.

Related Content

-

PHA Compound Molded into “World’s First” Biodegradable Bottle Closures

Beyond Plastic and partners have created a certified biodegradable PHA compound that can be injection molded into 38-mm closures in a sub 6-second cycle from a multicavity hot runner tool.

-

How to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

-

Latest Data on Bottled Water Shows Continued Strong Growth

Bottled water’s volume surpassed soft drinks for the first time in 2016 and has done so every year since.