Thermoforming Equipment Supplier Expands Virtual Services

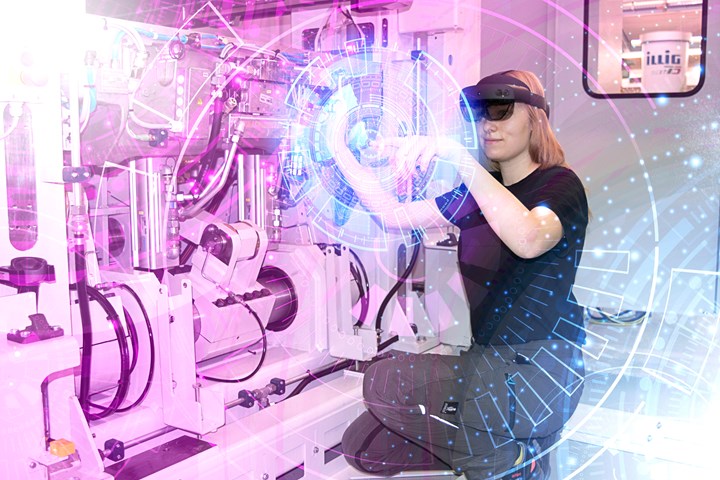

Illig has expanded its customer service program with augmented reality devices and software solutions.

Manufacturer of thermoforming and packaging systems Illig (U.S. office in Indianapolis) has expanded its customer service program with new virtual tools. Augmented reality (AR) devices and software solutions have been deployed to support customers remotely. The complementary visualization technologies enables the use of technical maintenance, machine health checks, as well as the execution of a variety of tests in the Illig Technology Center (ITC) in real time. Pandemic-related lockdowns and restrictions on global travel have accelerated the acceptance of expanded remote technical customer support.

Factory acceptance tests (FAT) and subsequent machine commissioning at the customer's site are usually carried out with the physical presence of Illig technicians and customer staff. Illig has offered the possibility to carry out these demanding and complex procedures online for years. Until now, the direct exchange took place via portable devices such as smartphones, tablets, and high-end cameras in real time.

Virtual services extends and facilitates communication in the commissioning process and speeds up execution of related tasks. With AR technology, Illig has expanded its digital service offering with the help of Microsoft HoloLens2. These mixed reality glasses allow the user to display interactive 3D projections in the immediate environment. Adapted to Illig's requirements, the glasses can be used, for example, for tests in the ITC with direct transmission to the customer. Customers can actively participate in real time from their location using Microsoft TEAMS via smartphone, tablet or PC. Other applications with this technology include FATs, customer training, and live product presentations.

Additional options for accessible live communication for ad hoc support includes the use of the Inosoft i40 software portal at Illig. This web-based real-time support enables simple and fast direct contact with the customer via moving image and sound without the customer having to install any special software.

Related Content

-

Thermoformer Maximizes Productivity with 3D Printing

Productive Plastics has created an extensive collection of 3D printed manufacturing aids that sharply reduce lead times.

-

ExxonMobil Develops High-Performance, 95% PE Recyclable Thermoformed Packaging

The packaging solution involved a collaboration with equipment suppliers Hosokawa Alpine and Multivac Group.

-

Sheet Extrusion, Thermoforming Tips for PLA/aPHA Blends

Biopolymers like PLA and PHA are able to meet sustainability goals while also delivering the performance attributes needed in rigid food packaging. Here’s what testing has shown.