color

Additives: New Color Effects for PET Packaging

Penn Color has developed some unique color packages in collaboration with Husky and PET Engineering.

Read MoreNPE2018 New Technology Focus: Additives

The broad range of new additives includes modifiers, silicone additives for various polyolefins, compatibilizers PET and PLA, a blowing agent reinforced nylons, flame-retardant synergists for wire & cable, unique colorants, and color-tracking software for liquid-color metering devices.

Read MoreNew Mold Monitoring System Promises Fast Processing Speeds and High Resolution

The full-color, high-resolution digital image processing technology serves to protect complex, expensive injection molds running sub 2-second cycles.

Read MoreChanging the Game in Liquid Color

Riverdale Global’s ‘Computerized Color’ technology and service offerings continue to evolve.

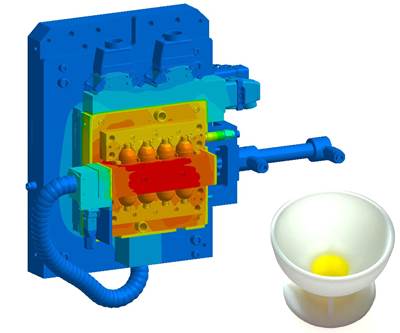

Read MoreTwo-Color LSR Molding Fine-Tuned with Flow Simulation

“Virtual Molding” simulation can model all aspects of LSR molding, even with two colors.

Read MoreOne-Step Color Masterbatch Production

KraussMaffei Berstorff Liquid Color Compounding Technology allows masterbatches to be run without the need for ‘mono-concentrate’ production steps.

Read More‘Mini’ Accumulator-Head Machine Comes to NPE

Small industrial blow molder with rapid color and material change.

Read MoreThe 3-to-7-Minute Color Change—Step 3: Color Planning

It is important to understand what to expect when changing from one color to another; here’s a method to analyze what steps must be taken from a cleaning standpoint.

Read MoreThe 3-to-7-Minute Color Change—Step 2: Preparation & Equipment

Hopper and screw and barrel considerations come into play as do strategies: press-side loading, satellite hoppers or a combination of both?

Read MoreQuick Changeover: The 3-to-7-Minute Color Change

Step 1: Assessment—These questions must be asked during the development of fast changeover procedures.

Read More