Film Extrusion

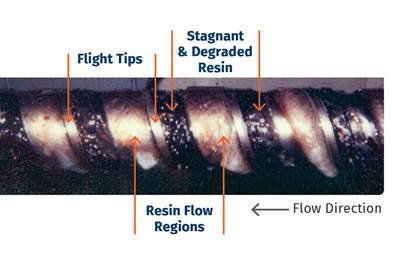

How Screw Design Can Mitigate Gels in PE Films

Gels are a constant issue in production of PE films using single-screw extruders. Gels can create quality issues via optical flaws, and they can cause the film to break on blown or cast film lines. There are numerous origins for gels, and the mitigation method depends on knowing the gel type.

Read MoreHigh-Output Air Ring for Heavy-Duty Bags

Air ring exceeds output rates of 1320 lb/hr and targets bags for form-fill-seal applications.

Read MoreSlitter-Rewinder Packed with Safety Features

Safety features comply with upcoming national and industry standards. Unit also features operator interface refinements that further improve productivity.

Read MoreRoll Stand Offers More Automation, Process Control

Processors benefit from technical and bottom line advantages of the roll stand’s inverted-down, multi-roll design.

Read MoreInnovative Film Gauge is 'Ultra-Accurate'

Said to provide the best-in-class, best-in-value measurement system on the market today.

Read MorePregis Names McClure President of South Carolina Film Extrusion Operation

Veteran film extrusion exec to head up $80 million facility.

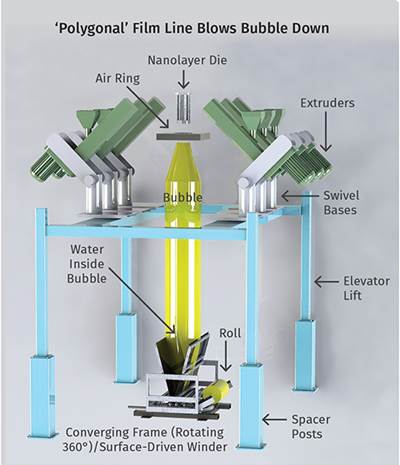

Read MoreCompact Line Turns Blown Film Processing Upside Down

Space-saving blown film line blows bubble down and is height-adjustable to optimize film temperature for the material.

Read MoreW&H Adds Kasie Fairbarn as Product Sales Manager

Fairbarn joins blown film machine builder with experience from both processor and brand owner sides.

Read MoreProductivity & Profitability ‘Turbo' Charged At Young, Growing Film Processor

Polymer Film & Bag adds extrusion capacity and new technology to make its two-year-old processing business more efficient.

Read MoreBandera Names New G.M. for North American Operation

Mattia Gambarotto is based out of Bandera U.S. LLC’s new office in Illinois.

Read More