LIM & LSR Molding

News in LSR Molding at K 2016

Two-color molding with one injection barrel and pumping system.

Read MoreK 2016 Injection Molding: Rapid Pace of Development

Servo drives dominate. Other trends include multitouch screens, adding materials data to process controls, and Industry 4.0 connectivity.

Read MoreVideo: Peter Neumann's Exit Interview

After 35 years (and 12 K Shows), Engel's Dr. Peter Neumann retired on Dec. 1, handing over the family held company to the next generation—his nephew.

Watch11th Hour Extension to Proposed Lockout/Tagout Rule Changes

Deadline extended from Jan. 1 to Jan. 4, 2017 as stakeholders weigh the potential impact on injection machine maintenance and mold changes.

Read MoreK 2016 Preview: Injection Molding

Adapting injection molding to the concept of Industry 4.0 is gaining momentum. At this show you’ll see that the interconnected, integrated “factory of the future” is almost here.

Read MoreThe 5 M’s of Molding—Part 5: Method

Once a molding problem has been identified, use “method” to determine whether the issue is with Man, Mold, Machine or Material.

Read MoreKraussMaffei Celebrates 50 Years in U.S.

The U.S. has become the largest single-country market for KM.

Read MoreNew Materials Shine Bright In Growing LED Market

Rapid expansion of LED technology has spurred development of new formulations for a wide range of lighting components. Here are examples of activity in this fast-moving field.

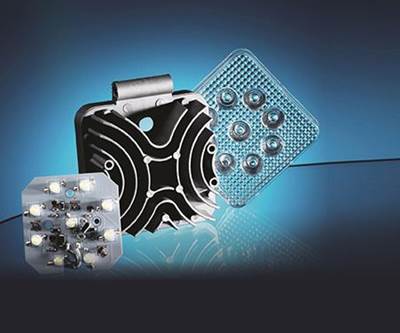

Read MoreLSR Developments in LEDs for Automotive and Street Lighting

LSR’s resistance to UV light and high temperatures allow direct contact to LED, while low injection pressure allows overmolding of sensitive parts.

Read MoreSimulation Meets Reality: Physical & Virtual Molding of LSR

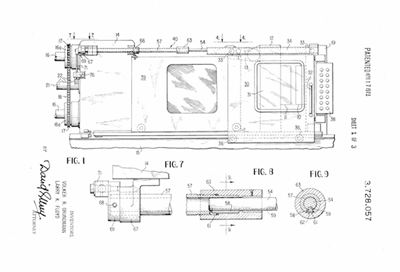

Growing sophistication in simulating the molding performance of LSR is evident in the case of this exceedingly complex part. Actual molding trials validated the predictions of simulated ‘virtual molding.’

Read More