LIM & LSR Molding

Minnesota Rubber and Plastics to Build Innovation Center

The medical focused injection molder says the new 9000-ft2 innovation center will give its customers a design-prototype-build-test outlet for the creation of new devices and components.

Read MoreFakuma: Boy Brings Eight Machines to Friedrichshafen

Neustadt-Fernthal, Germany based Boy will have four machines at its Fakuma stand this October, with an additional four presses running at partner booths.

Read MoreFakuma: Wittmann Battenfeld to Launch Machine Line at Friedrichshafen Fair

In addition to introducing its new SmartPlus line of servo-hydraulic injection molding machines, Wittmann Battenfeld will feature multiple machines at its booth and stream video of other cells from its labs.

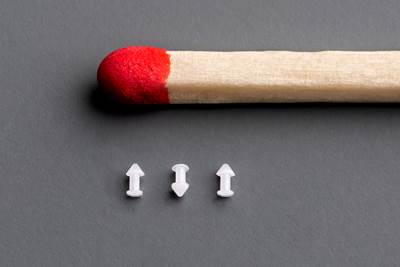

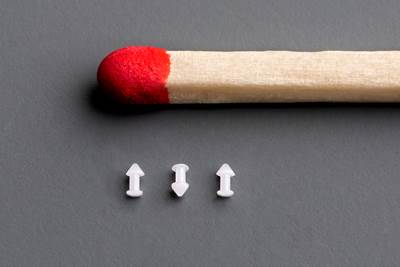

Read MoreMicro-Injection Molding LSR: Exploring the Limits of What’s Possible

Molding delicate LSR parts weighing 0.5 mg in 32 cavities requires high precision and repeatability in molding and careful post-mold handling. Here’s a look at the challenges of micro-molding with LSR and what makes it different from thermoplastic micro-molding.

Read MoreTrelleborg Expands Silicone Molding in Minnesota

Sweden-headquartered Trelleborg has expanded its Delano, Minn. facility, adding clean room silicone molding space.

Read MoreInjection Molding: New Micro-Injection Unit for LSR

Engel and collaborator ACH Solution say the new unit enables shot weights well below 0.1 g.

Read MoreNolato Group Acquires GW Plastics

The Vermont headquartered injection molding, moldmaking and contract manufacturing firm founded in 1955 becomes part of the global, publicly traded Swedish conglomerate.

Read MoreFakuma Show Goes On (Digitally) for Wittmann Battenfeld

Self-contained inline scrap integration; medical, LSR, and packaging Cells; an MES Upgrade and more to be introduced virtually.

Read MoreSimulation Software Speeds Mask Development

Sigma Engineering partnered with Arburg and others to expedite the design and optimization of a molded LSR mask, using simulation to determine mold setup, filling calculations and thermal layout in 24 hours.

Read MoreM.R. Mold & Engineering Completes Move to Larger Location

The California mold maker that specializes in tooling for liquid silicone rubber (LSR) completed the move into a new 23,000-ft2 space on March 31 amidst the coronavirus crisis.

Read More