Materials

EconCore Expands Continuous Production of Thermoplastic Honeycombs for Composites

ThermHex technology has been used successfully to produce honeycombs from several high-performance thermoplastics.

Read MoreNovel Flat Fiberglass Boasts Several Benefits for Thermoplastic Composites

Flat vs. round fiberglass allows higher fiber loading levels and better mechanical properties—including higher impact strength.

Read MoreHigh-Temperature Resistant PEKK and Modified PAEK for FDM

PEKK compounds, material for extrusion-based 3D printing processes and an endothermic blowing agent are highlighted.

Read MoreMaterials: LSR Grades Offer Low-Temperature Curing, Primerless Adhesion to Copolyester

Curing at a lower temperature makes it feasible to overmold the materials onto heat-sensitive substrates, including copolyesters.

Read MoreMaterials: New LSR Cures, Forms in the Body

Patented LSR delivery system allows implantation of pre-sterilized materials for in-situ cure and forming within the body.

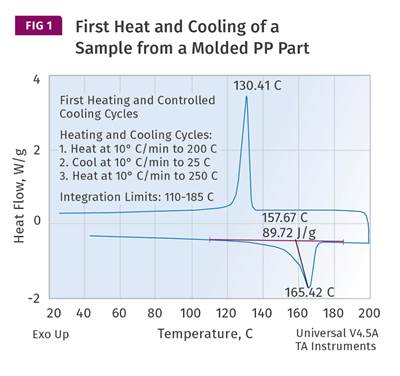

Read MoreA Processor’s Most Important Job, Part 3: Unintended Consequences

Processors are often expected to compensate for ill-advised decisions made earlier in the product-development process. In the case of shrinkage, one of the most common ‘fixes’ is to simply reduce the mold temperature.

Read MoreNovel ‘Flat’ Fiberglass Enhances Injection Molded TP Composites

Advances in fiberglass reinforcements for thermoplastics have evolved from conventional chopped strand to long-glass fibers to hybrids of long glass and carbon fibers.

Read MoreLow-Gloss PVC Compounds for Automotive Window Encapsulation

OEM-approved Apex 1523-LG compounds from Teknor Apex retain PVC cost advantage over elastomers, are scratch- and mar-resistant, and facilitate precise color matching.

Read MoreLyondellBasell to Acquire A.Schulman

Acquisition to create an industry-leading compounding business.

Read More