nanocomposites

Plastic Pallets Gain Ground In an Eco-Conscious World

Low-cost wood is still king, but plastics’ reusability is a growing attraction among manufacturers looking for sustainable material-handling options. The one major hurdle is today’s high resin prices.

Read MoreInvesting in Planet-Friendly Packaging

Clear Lam Packaging Inc. is a mid-sized, family-owned packaging company with an enviable growth rate of over 20%/yr, unusual at a time when many mid-sized packaging companies are being bought out and disappearing. The secret, Clear Lam believes, has been its aggressive investment in R&D.

Read MoreNew Biopolymers Find Commercial Use

Two promising new biopolymers are finding some initial commercial applications.

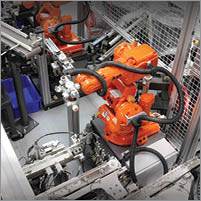

Read MoreComposites Embrace Mass Production

The focus this year at the international JEC Composites Show in Paris was not so much on brand-new processes as on adapting existing processes and materials for mass production, especially of large parts with critical structural demands. Attracting the most attention was wind energy, where composite material usage is growing more than 17%/yr, according to Gurit (formerly SP Systems), a Swiss-based global prepreg supplier with U.S. operations.

Read MoreEnhancing Biopolymers: Additives Are Needed for Toughness, Heat Resistance & Processability

Plastics are going “green,” but they will need some help to get there. Biodegradable polymers derived from renewable resources are attracting lots of interest and publicity, but that enthusiasm is counterbalanced by persistent questions of availability, cost, performance, and processability. All these issues are inter-related: Increasing demand will lead to more capacity, which will presumably lead to lower prices. But the foundation is market demand, which ultimately depends on whether biopolymers will have the performance properties and processability to compete with existing non-renewable plastics.

Read MoreClariant and Bayer Partners In Nanotube Compounds

To take advantage of the electrical conductivity and mechanical strength afforded by carbon nanotubes (CNT), Bayer MaterialScience AG in Germany (U.S. office in Pittsburgh) and Clariant Masterbatches (U.S. office in Winchester, Va.) signed a long-term cooperation agreement for development, production, and sales of CNT/thermoplastic compounds and masterbatches.

Read MoreBASF Boosts Degradable Resin Capacity

BASF AG in Germany (U.S. office in Florham, N.J.) plans to expand its capacity for Ecoflex biodegradable aliphatic copolyester from the current 30 million lb to 132 million lb/yr by the third quarter of 2010.

Read MoreClear Road Ahead for TPOs, TPVs

Olefinic TPEs originally comprised only two classes of rubber-modified polypropylene, known as TPO and TPV. More recently, these have been supplemented by new types of olefinic elastomers that can be used on their own or as the rubber component in TPO/TPV compounds. Additionally, a small handful of specialty TPEs using olefinic matrices occupy niche applications.

Read MoreTPEs Move Up the Performance Scale

This first of two articles on directions in TPE development focuses on styrenic, copolyester, polyamide, and TP urethane elastomers. The following article covers olefinics—TPOs, TPVs, and POEs.

Read More