Tooling

Leading-Edge Molding Technology Installed at ORNL

Roctool’s induction-powered heating/cooling equipment to further development of composites.

Read MoreTooling: Dealing with Sprue Bushings On the Production Floor

Causes of and solutions to some problems you probably deal with every day.

Read MoreVirtual Tool Alloy Selection Confirms Benefits in Cost & Part Quality

Using simulation to understand cost-benefit ratio in using tool alloys with high thermal conductivity.

Read MoreSeeking Moldmakers That Are Fast…and Smart

Now in its 15th year, MoldMaking Technology’s Leadtime Leader Award is once again seeking out tool shops that get things done.

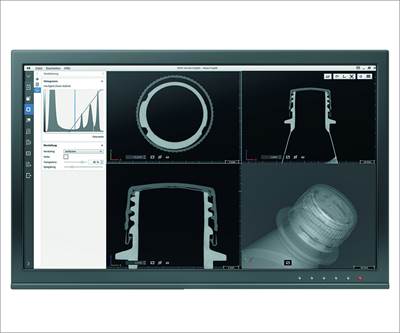

WatchHow CT Scanning Can Cut Your Product-Development Time

Computed tomography scanning offers molders a wide range of benefits, often saving them hundreds of hours during the processes of mold building, mold tryout, and first- article approval. Here’s what you need to know.

Read MoreMold Performance: Tap Into the Power of Data Collection

Collecting core data in a transparent way allows molders to drill into the true cost of tooling issues and develop real goals to keep production flowing.

Read MoreTooling: Critical Design Considerations for Sprue Bushings

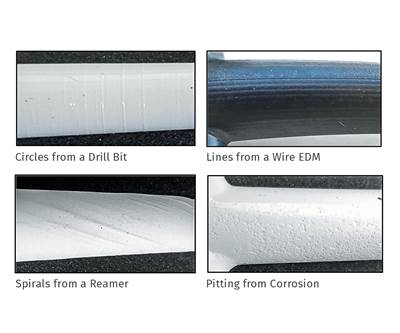

Among them are good cooling, proper orientation, solid retention, structural integrity, generous radii, and an appropriately polished bore.

Read MoreMedical Molder Sweats the Small Stuff to Deliver Big Results

Embracing lean manufacturing and scientific molding keeps Freudenberg Medical on top of customer demands for defect-free deliveries as it expands into full device manufacturing, 100% automated inspection, and 3D-printed tooling for quicker product launches.

Read MoreTooling: Reducing the Mass In Sprue Bushings

Important and frequently overlooked details of sprue-bushing design can improve the process and profits for an injection mold.

Read MoreCould Additive Manufacturing Technologies for Moldmaking Make EDM Obsolete?

As the machinery and materials advance, some moldmaking companies at the forefront of additive manufacturing believe it could reduce or eliminate the need for some more traditional technologies, like EDM and gundrilling.

Read More