scientific molding

Injection Molding: Safety First—Know the Compatibility of Different Resins

Certain materials don’t play well together when mixed. So it’s best not to. Here are some guidelines.

Read MoreInjection Molding: Process Documentation Is Crucial to Making ‘Identical’ Parts

Use a machine/mold setup sheet to document plastic parameters and use them on any acceptable machine into which the mold is placed.

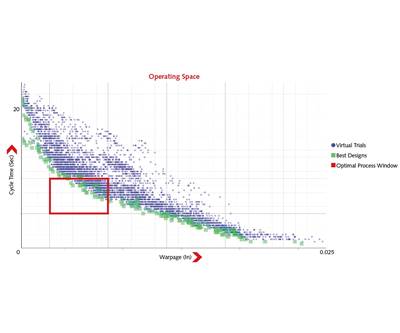

Read MoreAutomate Injection Molding Simulation With Autonomous Optimization

Simulation not only predicts how a mold will fill, but also provides guidance to make it fill better. The new technology of Autonomous Optimization automatically performs hundreds or thousands of simulations, testing multiple variables—gating, venting and cooling, for example—and learning which combinations help achieve objectives for injection pressure, cycle time, warpage, etc.

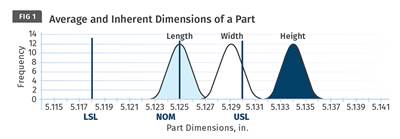

Read MoreImproving Molding Process Capability: Understanding the PVT Graph, Part 1

Process capability is related to the variation in part dimensions from shot to shot. High values of process capability require the shrinkage of the material to be identical on each shot, which can be confirmed from the pressure-volume-temperature (PVT) graph.

Read MoreGetting Started with Medical Molding: First Consider the ‘Four E’s’

Global medical molder Nypro provides first-hand guidance on what you need to get into the medical molding business.

Read MoreInjection Molding: A Practical Approach to Calculating Residence Time

Toss the formulas. The best way to determine residence time is to conduct a simple experiment.

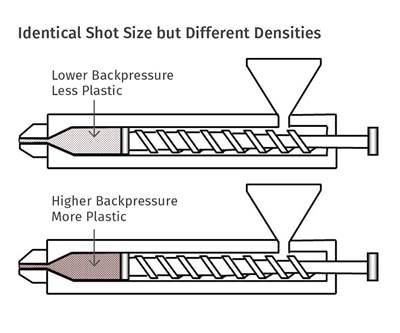

Read MoreInjection Molding: How Backpressure Adjustments Influence Shot Size

Raising backpressure results in increasing shot size, which can cause a host of other problems.

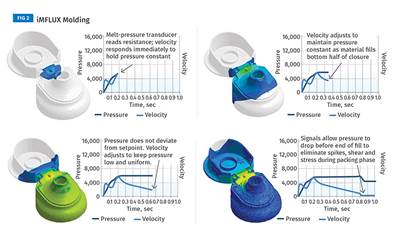

Read MoreA New Way to Mold Better Parts Faster and Easier

A new injection molding process ‘breaks all the rules’ by using low, constant pressure to achieve faster cycles and better-quality parts.

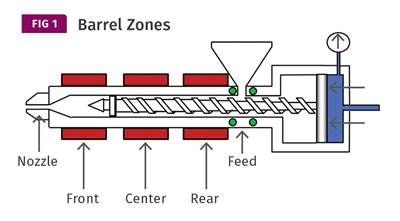

Read MoreInjection Molding: How to Set Barrel Zone Temps

Start by picking a target melt temperature, and double-check data sheets for the resin supplier’s recommendations. Now for the rest...

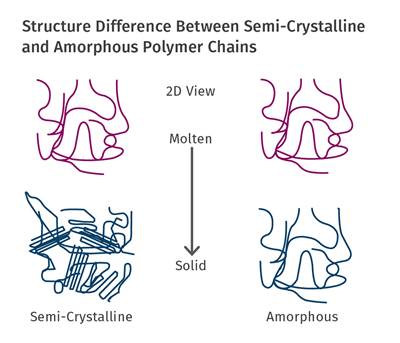

Read MoreInjection Molding: Melting Amorphous vs. Semi-Crystalline Plastics

Understanding the differences in how each melts is crucial to obtaining melt uniformity.

Read More