scientific molding

Screw Speed Versus Recovery Time

Many molders don't take screw-rotation speed into account when developing a process for a new mold. Here's why they should.

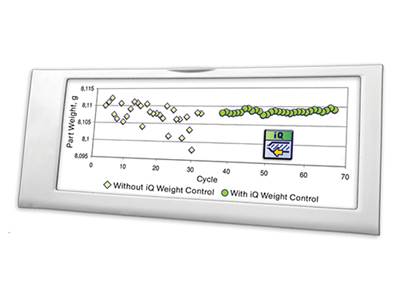

Read MoreSwitch Over To Consistent Quality

A new process-control method picks up variations in melt quality and viscosity during the injection phase and equalizes them within the same shot.

Read MoreShutting Down & Starting Up An Injection Molding Machine

Whether your press is going down for repairs, a holiday, or a slow production schedule, proper shut-down and start-up procedures must be followed.

Read MoreMRPC Takes ‘Holistic’ Approach To Scientific Molding

Last year this family-owned molder made a major commitment to Scientific Molding by starting a training process involving all employees.

Read MoreDon’t Overlook Gate Location

Molders take heed: Gate location is the root cause of many molding difficulties. You’ll be doing yourself a big favor by spending some time and thought in determining the best gate location. Here’s what to look for.

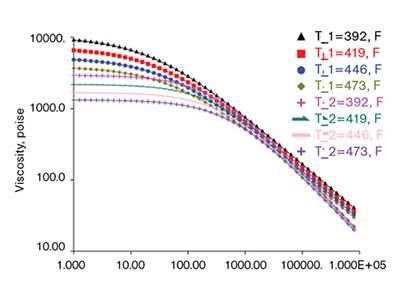

Read MoreMold Simulation: Get Best Results With Good Materials Data

Want the best results from your flow analysis software? Of course you do. But you stand a better chance for success if you pay particular attention to the material data used by the software.

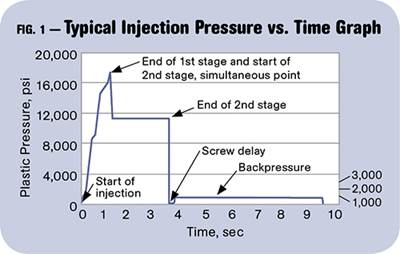

Read MoreHow to Establish an Acceptable Range for Pressure at Transfer

Pressure at transfer tells you the viscosity of the resin, providing the fill time is the same. Monitoring pressure at transfer—or better yet, the integral under the pressure vs. time curve—provides insight into the process.

Read MoreImprove Profits by Graphing Injection Pressure

Graphing is a powerful aid in optimizing the process and troubleshooting both process and machine issues.

Read MoreWhat to Calibrate on Your Press

There are different approaches to meeting the goal of making parts identically. At the heart of all them is the process or the machine setup sheet. My bet would be you cannot find two that are identical.

Read MoreWhy Multi-Cavity Molds Fill Unevenly

Balanced filling is critical for making identical parts, achieving high CPKs, holding tight tolerances, and getting “good” data from design of experiments.

Read More (2).jpg;maxWidth=970;quality=90)