A Processor’s Most Important Job, Part 8: Molded-In Stress

How processing adjustments can control molded-in stress.

This is part eight of an eleven-part series focused on the most important job of a processor. To read the rest of this series, click these links:

part one, part two, part three, part four, part five, part six, part seven, part nine, part ten, part eleven.

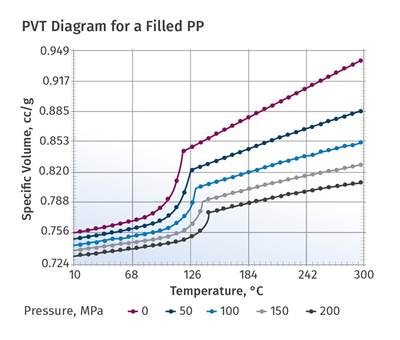

In our review of characteristics that can be controlled to a significant extent through processing, the next item on the list is internal stress in the part, also referred to as molded-in stress. Stress arises from two primary influences: Differences in pressure and differences in the rate at which the polymer cools within the part. Flowing molten polymer exhibits a loss in pressure through the system that is related in part to the distance and the cross-sectional area through which the material flows.

Therefore, there will be a measurable pressure gradient across any molded part as the material flows from the gate to the last places in the cavity to fill. This variation in pressure will produce variations in the degree to which the material shrinks.

The Cooling Rate Effect

Cooling rate also influences the shrinkage of material. Even when the cooling-line layout in a mold is done with meticulous attention to detail, which rarely happens, differential rates of cooling are still inevitable due to wall-thickness considerations. Material close to the mold surface will cool faster than the material in the part core. The greater the wall thickness of the part, the more problematic this will become.

When molders fail to deal with root causes and elect to either fixture a part to prevent movement while it cools, or alter the processing conditions to reduce warpage, they are often building in even higher levels of stress.

Orientation is another factor associated with the behavior of the different layers of material flowing through the mold. Polymer chains naturally form an entangled network where the molecules are coiled up. However, when molten polymer flows, differences in the shearing forces between the various layers of flowing material cause the chains to straighten and orient in the direction of flow. This is the mechanism that causes non-Newtonian behavior in polymers.

Shear rates are at their highest just below the part surface, and this is also the layer that cools most rapidly. This rapid cooling limits the time that the polymer chains have to relax from the oriented state to the coiled state. Therefore, the material near the wall will exhibit a relatively high degree of retained orientation in the final part. The level of this orientation will decrease as we move to the center of the part. Not only is the gradient in orientation between the surface and the core a source of stress, but in fiber-reinforced materials, anisotropic shrinkage is caused by the limitations that the oriented fibers place on the dimensional change in the polymer as it cools. This limitation is not observed in the direction transverse to flow, or at least not to the same extent.

The Melting Process Effect

Consequently, any fabricated part will contain some level of internal stress that arises naturally from melt processing. In many cases, these stresses will appear as warpage. Warpage is the natural result of shrinkage that varies in magnitude within a part, whether it be due to volumetric considerations or driven by orientation. But even if warpage is not evident in the part, stresses are still present. Often, they do not show up until the part is in the field and experiences an environmental condition such as elevated temperature, contact with a certain chemical, or an impact event. Elevated levels of stress will result in a less-than-optimal response to these application influences.

Warpage is one of the mechanisms by which stress is relieved. When molders fail to deal with root causes and elect to either fixture a part to prevent movement while it cools, or alter the processing conditions to reduce warpage, they are often building in even higher levels of stress. Most processors know that reducing the temperature of the mold is a very effective way of reducing warpage. We have discussed the temporary nature of this improvement when talking about semi-crystalline polymers. But what about materials that do not crystallize?

How do amorphous polymers like polycarbonate, ABS, and polysulfone react to the faster cooling rate associated with a lower mold temperature?

A study performed on ABS some years ago offers some insights into this question. The accompanying graph shows the results of this study; an evaluation of the effect of mold and melt temperatures on the impact resistance of test specimens molded from a particular grade of the polymer. ABS is generally considered to be a reasonably tough material, and materials in this class will typically produce falling dart energies-to break in the range of 30-40 nanometers (22-30 foot-pounds) and exhibit a ductile failure mode. However, note that when specimens were prepared in a mold set at a relatively low temperature of 84°F (29°C) the energy required to break the test specimens was only 1.5 nanometer (1.1 foot-pounds), a value associated with a very brittle material.

Altering the melt temperature across a fairly wide range from 425°F (218°C) to 525°F (274°C) did not appreciably change this result. However, when the mold temperature was increased, the impact resistance improved dramatically. With the mold temperature set at 185°F (85°C), the impact resistance improved to 30 nanometers (22 foot-pounds) with the melt temperature set at the upper end of the experimental range. This improvement is attributable to the smaller difference in cooling rate between the surface material and the core material, coupled with a reduction in the thickness of the oriented layer of material. Both factors reduce the level of molded-in stress in the part, making it more capable of managing an externally applied stress.

The natural response of most processors, when presented with these data, is to protest that the cycle time will be longer if the mold temperature is increased. However, this objection can be answered by observing what occurs when the melt temperature is reduced.

Lower Melt Temperatures

While lowering the melt temperature had little to no effect on part performance when the mold was cold, the same adjustment produced an additional improvement in impact resistance when the mold temperature was increased. The best results, impact resistance of 48 nanometers (35 foot-pounds), were achieved with the lowest melt temperature and the highest mold temperature. By reducing the melt temperature, the increased mold temperature can be managed without changing the cycle time.

Any fabricated part will contain some level of internal stress that arises naturally from melt processing.

The best way to remove heat quickly is not to introduce it in the first place. The lower melt temperature also reduces the risk of polymer degradation. This behavior can be verified by using another measure of molded-in stress, resistance to stress cracking. When molding some clear PC parts using a relatively high melt temperature of 610°F (321°C) and a low mold temperature of 75°F (24°C), it was observed that the parts developed cracks when exposed to olive oil. In fact, parts molded at these conditions spontaneously developed cracks even without exposure to the olive oil if enough time was allowed to pass after the parts were produced.

When the mold temperature was raised to 221°F (105°C) and the melt temperature was reduced to 530°F (277°C) the stress cracking was eliminated without lengthening the cycle time.

The part surface also had a better appearance because the higher mold temperature delayed the rate at which the surface material solidified. These are anecdotal results, and in the world of plastics, everyone has a good story or two. But this does not pass for science.

In our next article, we will elaborate on the foundation principles behind these improvements and translate them to the process conditions that ensure optimal performance for the molded part.

About the Author

Michael Sepe

Michael Sepe is an independent, global materials and processing consultant whose company, Michael P. Sepe LLC, is based in Sedona, Arizona. He has more than 40 years of experience in the plastics industry and assists clients with material selection, designing for manufacturability, process optimization, troubleshooting and failure analysis. Contact: 928-203-0408 • mike@thematerialanalyst.com.

Related Content

Where and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.

Read MoreInjection Molding: Focus on these Seven Areas to Set a Preventive Maintenance Schedule

Performing fundamental maintenance inspections frequently assures press longevity and process stability. Here’s a checklist to help you stay on top of seven key systems.

Read MoreThe Effects of Stress on Polymers

Previously we have discussed the effects of temperature and time on the long-term behavior of polymers. Now let's take a look at stress.

Read MoreHow to Select the Right Cooling Stack for Sheet

First, remember there is no universal cooling-roll stack. And be sure to take into account the specific heat of the polymer you are processing.

Read MoreRead Next

A Processor's Most Important Job, Part 7: Reviewing Crystallinity

There are several process-related issues that influence crystallinity besides cooling rate. Let’s examine a few.

Read MoreA Processor's Most Important Job, Part 9: Avoid Molded-In Stress

How to establish molding conditions that minimize internal stress in a part.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More

.jpg;width=70;height=70;mode=crop)