Advances in Materials, IML and Tooling Highlight Rotomolders' Meeting

Several new resins and additives that raise part performance and improve processability were launched at the recent 32nd Annual Fall Meeting of the Association of Rotational Molders (ARM) in Detroit.

Several new resins and additives that raise part performance and improve processability were launched at the recent 32nd Annual Fall Meeting of the Association of Rotational Molders (ARM) in Detroit. The conference also featured a simple and efficient in-mold labeling system, a unique tooling device to create holes and openings in the mold, and new clamshell and shuttle machines.

High-Output Resins

Nova Chemicals introduced Surpass RMs341-U/UG, an octene HDPE copolymer with a balance of exceptional processability and stiffness. It has 3.5 MI and 0.941 density. In applications such as chemical and water tanks, cycle time is reduced 10% to 15% vs. a comparable 2-MI resin, Nova claims. It reportedly can fill complex parts as well as can a 5-MI hexene copolymer. Very low catalyst residues are said to provide superior whiteness and easy demolding. Other applications include marine equipment and waste containers.

Meanwhile, new hexene copolymers from Equistar Chemicals include Petrothene GA675662, an LLDPE with improved stiffness at no sacrifice in impact strength. It has 5.2 MI and 0.939 density and is for RV and marine applications. Petrothene GA672762 is a new HDPE with greater stiffness than standard resins for large tanks from 200 to 16,000 gal. Thinner walls are said to be possible and ESCR is not sacrificed.

ICO Polymers claims to have the first crosslinkable semi-conductive PE compounds for rotomolding. Icorene CX-1503 provides high flame resistance and toughness for demanding static-sensitive applications. Its typical surface resistivity is 106 ohm/sq and flexural modulus is 99,900 psi.

Another new compound, Icorene C-420, is a non-crosslinkable semi-conductive LLDPE that is stiffer than previous grades. It has a flex modulus of 101,350 psi, low-temperature impact of 19 ft-lb, 5 MI, and 0.931 density.

A new nucleating agent from Milliken Chemical is being adapted to MDPE rotomolding resins. Already commercialized in packaging film, Hyperform HPN20E is said to provide faster cooling without warpage. The additive helps PE to crystallize faster, reducing cooling time. The first commercial use is a rotomolded water tank in Latin America, which boasts a 30% to 40% productivity improvement.

In-Mold Labeling

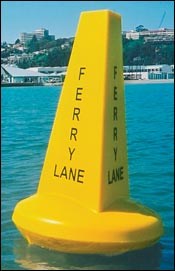

New labeling approaches are emerging to help rotomolders meet growing customer demand for product traceability, name-brand recognition, and decorative quality. The latest is a new in-mold labeling (IML) system from New Zealand’s Polymer Systems International Ltd. It reportedly eliminates many of the limitations associated with applying graphics to already molded parts. The company is represented here by Paladin Sales.

The olefin-based opaque label is compatible with PE and is placed manually in the mold, which can be at virtually any temperature. This enables molders to keep cycle times to a minimum by not requiring longer cooling times to bring molds within a low temperature range. No spray adhesive is required because the label carries its own. For applications where IML isn’t practical, the label can be rolled onto a reheated part in a post-mold operation.

Machinery News

Ferry Industries introduced a new generation of clamshell and shuttle machines. The newest RotoSpeed single-station clamshell has a flexible independent cycle control and electric ballscrew actuation instead of hydraulics. Air flow is said to be improved significantly and load-carrying capacity is up 20% to 4000 lb. This compact model is targeted for low-volume complex parts.

The next-generation RotoSpeed shuttle is a modular system with one or two arms sharing a common oven. Each arm has its own independent processing cycle. An aerodynamic oven helps optimize energy efficiency. Six models have mold swing up to 218 in. and carrying capacity up to 7500 lb.

Tooling Advances

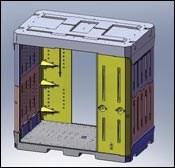

Norstar Aluminum Molds and German toolmaker Maus have developed unique tooling attachments called Freeforms that form holes and other openings in parts during the molding process. They eliminate the need for drilling or routing afterward. Freeforms are made of a high-temperature, castable silicone that does not allow the molten resin to stick. They both form the holes and facilitate easy demolding.

Freeforms come as standard or custom preformed inserts that attach through holes in the mold wall. They can be attached to loose mold pieces or cast onto the surface of the mold, creating free-form shaped openings. They can create holes as small as 0.25 in. either parallel or perpendicular to the line of draw.

New AutoMatic Mold Jacks from Paladin Sales are patented mold-opening devices that prevent problems in unloading parts caused by mold halves sticking together. Once a hoist lifts the four hooks, the mold jacks are actuated and pushed down on a plate attached to the bottom of the mold or spider to force the mold apart. No pry bars are required, and the jacks reportedly open the mold evenly so that no damage occurs to the parting line or the machine arm. In addition, they help seat the mold halves evenly and smoothly upon mold closing, again preventing damage to parting lines. A set of four mold jacks costs about $650.

A quick-mold-change system from Cole Industries claims to reduce changeover time by 75%. It consists of a 1-in.-thick slide plate that is welded to the spider and a 1-in.-thick mounting plate with two tapered pins. A tapered slide creates a positive lock to join the two plates with one bolt. The patent-pending device costs $850.

Award-Winning Parts

Winners of the ARM parts competition included the Cosmo container, claimed to be the industry’s first plastic collapsible container for the portable storage and moving market. The 700-lb, 8 x 5 x 8 ft PE container, developed by Nova Chemicals, collapses to less than one-third of its height when empty. The prototype design, slated for commercial production early this year, replaces wood and metal storage boxes.

Another innovative application was the industry’s first rotomolded fence from SimTek Fence, Orem, Utah. The simulated rock privacy fence is designed to fill a gap between extruded PVC and real stone. It consists of foam-filled posts and rotomolded hollow panels that are steel-reinforced at the top and bottom. The 6 x 6 ft panels include 120 hidden kiss-offs for structural integrity. Tongue-and-groove assembly accommodates thermal expansion.

The parts are molded from a granite-effect compound from Chroma Corp. formulated for long-term weatherability. Overall performance is said to be better than PVC in terms of impact, UV resistance, and wind load. Installed cost is about $40 to $55/ft vs. $20 to $35/ft for PVC.

Related Content

BASF Highlighting How They 'Make, Use and Recycle Future Solutions'

NPE2024: BASF is using its proprietary computer-aided engineering tool Ultrasim when designing for sustainability in a broad range of industries.

Read MoreTosaf’s Investments in North America Result in 40% Increase in Production Capacity

Backed by a global presence, Tosaf provides localized additive and color solutions, and services for the plastic industry in North America.

Read MoreIntrinsic Viscosity Enhancer for rPET and PET Food-Contact Applications

Nexam’s Nexamite MO2100 rebuilds molecular weight and increases IV to enable upcycling of rPET.

Read MoreCompatibilizer for Nylon/ABS Alloys

CAI Performance Additives’ ST-AN3230 has shown to improve both compatibility and performance of nylon/ABS alloys.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More