Aluminum Injection Tooling: How to Use & Maintain It

Part II of III

Injection molders and major tier suppliers across many industries are looking to save money anywhere they can on part costs. Aluminum tooling for high-volume injection molding is now emerging as an attractive option for an increasing number of applications because it can reduce cycle times dramatically, speed mold construction, and trim tooling costs. A successful application in aluminum tooling typically runs 20% to 40% faster (and sometimes a lot more) than the same part running in a steel mold. That translates into a cost advantage for molder and customer that is difficult to match. What that means in practical terms is that once you’re running a part in an aluminum tool successfully, your chances of losing that part to another molder—one who is not experienced with aluminum molds and would stick with conventional steel—are cut practically to zero. We’ve identified some critical guidelines to make sure the transition to an aluminum tool for high-volume production goes smoothly.

In the first part of this series (in January), we focused on what is driving this trend and things to look out for when considering your first aluminum tool and some useful guidelines. In this article, we’ll discuss key considerations when doing actual molding and maintenance with aluminum molds and how they differ from more familiar steel tools.

GET USED TO RUNNING FASTER

First off, molding with an aluminum tool requires an entirely different approach than molding with a P-20 steel tool. What works with steel doesn’t work with aluminum. We’ve seen multiple instances where running in aluminum with the same process parameters as a steel tool results in problems like excess scrap as well as cosmetic issues like knit lines, pin push, flash, and drag marks.

As a builder of aluminum tools, we’ve found that part of our responsibility is to meet with molders—everyone from the engineering manager to the machine technicians—up front to help them understand the differences between steel and aluminum before the first trial. The key to a successful molding process with an aluminum tool is to change your operating culture to maximize the productivity potential that can be achieved with aluminum. One main point I make to them, and the single most important idea I wish to express in this article, is that the process must match the tool material, and not the other way around.

The other main point is that molders need to consider how their molding operations must adapt to take full advantage of the speed opportunities that come with aluminum. So many things happen faster with aluminum than with steel. For example, molders will be initially surprised at how quickly an aluminum mold will reach processing temperature at start-up due to its superior thermal conductivity, which is at least five to six times that of typical steel tools. This means not only that more parts can be produced per shift, but machine downtime for mold changes will be dramatically reduced. With greater machine utilization, more parts can be produced on fewer pieces of equipment. Time wasted is money left on the table, and molders will have to adjust to a significantly different rhythm in their molding operations than they’re used to with steel.

Since aluminum pulls the heat out of a part faster, you should be looking to eject the part out of the tool as quickly as possible. It also means that you can fill the tool faster with reduced shot times and lower injection pressure. If you monitored the actual steel temperature during a molding cycle with an aluminum mold, it would show a rapid spike in temperature during injection followed by an equally rapid reduction in mold temperature. For a steel mold, the temperature profile would show a slower, more gradual rise in temperature followed by a gradual decrease in temperature. Rapid heating of the aluminum mold during injection facilitates molding at lower pressure. And due to rapid cooling, there is no tradeoff in overall cycle time. Thus, molders can save time at different points of the molding cycle. It also means that you can typically run an aluminum tool with lower clamp tonnage than with steel.

MAINTENANCE & REPAIR

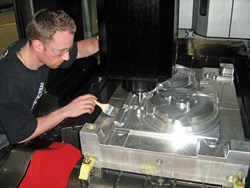

There is usually no more overall maintenance required for an aluminum tool than for steel, but there are different things to look for. For example, the rapid cycle times typically achieved by aluminum tools mean much more gas is released. This means the parting lines should be wiped down more often than with steel tools. That is not a lengthy process, typically just five or 10 minutes, but whereas you might wipe down parting lines once a week or so on a steel tool, you need to check for buildup on aluminum parting lines more frequently. Our customers also tell us that textured aluminum mold surfaces require more frequent cleaning.

One of the biggest differences in repairs for many of our customers concerns their ability to weld aluminum successfully in-house. Most every good molder can do small weld repairs on P-20 steel tools, but many find that they need to send that work out for aluminum molds. Molders using aluminum tooling will find it worthwhile to consult frequently with their mold material suppliers, as the major aluminum manufacturers are introducing new tools and techniques for welding tooling-grade aluminum.

Finally, molders need to rigorously monitor the performance of their molding machines. Our company policy is to place a maintenance schedule on every tool we deliver. In particular, molders should calibrate their production machines on a regular basis for things like parallelism and alignment. While this is no more a problem for aluminum tools than it is for steel, our experience over the course of the last 25 years is that just about every molder would do well to pay more attention to machine parallelism and alignment as part of its maintenance activities. A modest investment in molding machine maintenance now can save a lot of money later if a tool needs major repair.

In summary, aluminum tooling represents one of the best opportunities to come along in decades for molders to lock-in profitable business with minimal risk of losing the job to competitors, either in North America or abroad. The secret is speed. Molders who are considering using aluminum tooling need to be ready for it, and be ready to embrace it.

About the Author

After his father founded Unique Tool & Gauge in 1982, Darcy King joined the firm in 1995 and worked in every phase of operations, becoming president in 2005. Unique specializes in complex, multi-material injection molds and employs 70 people in Windsor, Ont. (519) 737-1159 • unique-tool.com

Related Content

A Systematic Approach to Process Development

The path to a no-baby-sitting injection molding process is paved with data and can be found by following certain steps.

Read MoreBack to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

Read MoreHow to Reduce Sinks in Injection Molding

Modifications to the common core pin can be a simple solution, but don’t expect all resins to behave the same. Gas assist is also worth a try.

Read MoreKnow Your Options in Injection Machine Nozzles

Improvements in nozzle design in recent years overcome some of the limitations of previous filter, mixing, and shut-off nozzles.

Read MoreRead Next

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More