Answering the Sustainability Challenge with Digitalization

Attendees in the molding halls of K can count on exhibits that address two main themes: digitalization and sustainability. Digitalization in the form of smarter pieces of equipment communicating with each other and with plant personnel; and sustainability in the form of greater energy efficiency and the ability to process recycled and renewable resins.

Trade shows and exhibitors often coalesce around bigger themes informed by broader society trends. Injection molding technology suppliers at K 2022 will certainly demonstrate that tendency this October in Düsseldorf, but what might be different this time around is the consistency and urgency these companies are showing to address consumer and government challenges to plastics that have evolved to the point of restrictive legislation and sector-wide regulatory plans.

So laser-focused are this show’s exhibitors on helping their customers meet the current and coming sustainability challenges that not only will their own booths feature equipment geared towards a more circular and digital future, but many will also have cells running at the VDMA’s Circular Economy Forum—a new temporary exhibition space housed in the inner courtyard of the exhibition grounds between the machinery halls. (VDMA is the organization of German machine builders.)

For example, at Arburg’s booth and its arburgGREENworld pavilion in the VDMA Circular Economy Forum, the stated goal is “to sustainably reduce the carbon footprint in plastics processing and feed the recyclable plastics material back into the materials cycle.” Arburg says digitalization enables sustainability by empowering targeted sorting and recycling of plastics. Tools include the R-Cycle initiative and marking technologies such as watermarks or QR codes that are applied to products during the manufacturing process. In addition, the company’s Gestica controller can be outfitted with various digital assistance systems to help molders overcome the inherent inconsistencies that come with running recycled materials.

The arburgGREENworld pavilion in the VDMA’s Circular Economy Forum will feature an all-electric Allrounder 370 machine molding Fischer’s Greenline brand of construction anchors or plugs. Featuring its “recyclate package” and a Multilift robot, the Allrounder will automatically deposit sprues into a granulator, which will break down the scrap and reintroduce it to the machine to mold more parts.

Sprues created from the molding of Fischer’s Greenline construction anchors will be gathered, ground and re-molded into new anchors at the K. (Photo: Arburg)

Arburg’s main booth will feature eight automation-equipped Allrounder injection machines from 35 to 663 metric tons, utilizing hydraulic, hybrid and all-electric configurations. In addition, the booth will be running two Freeformer 3D printers from Arburg’s industrial additive-manufacturing unit. Automation and robotic systems at the show will be part of turnkey production cells connected to the arburgXworld customer portal. For the first time, visitors will be able to see the new Varimos molding simulation plug-in from Simcon, which uses artificial intelligence to show how changes to machine parameters impact the molding process. Varimos works with Simcon’s Cadmould simulation software to quickly develop and test mold-design iterations.

Three Allrounders will be running the company’s recyclate package, which is intended to ease the molding of recycled materials. Arburg describes this as a combination of a modified injection unit and smart process control. Available on all Allrounder machines, including via retrofit, the recyclate package features a modified cylinder for smooth feeding of recycled materials that might have poor flow characteristics. The screws feature a specialized geometry and a CrN coating to reduce deposit formation and resist wear, while the barrel temps can range up to 450°C (842°F). Additional control features include aXw Control PressurePilot, which requires Arburg’s ScrewPilot control feature, standard on electric and hybrid Allrounders and optional on hydraulics (though not available for Golden Edition presses).

K visitors can see the recyclate package in action an electric Allrounder 470 A molding PP handles from PCR. They can also see the package running on a hydraulic Allrounder 270 S compact, molding glass-reinforced PPS recyclate into tweezers. In addition, in a pilot project by Arburg and Telekom showcasing secure 5G mobile connectivity, a networked compact turnkey system based on an Allrounder 375 V with a six-axis robot and Arburg Turnkey Control Module (ATCM) will mold a bicycle tool from recycled 50% glass-filled nylon 66/6.

Additional machine displays include a hybrid packaging Allrounder 630 H featuring a cleanroom design and molding around 18,000 transparent PET blood tubes per hour. The press communicates with the mold, hot-runner controller, dryer and automation via the Gestica control and OPC-UA communication protocols. The 32-cavity tool from Hack Formenbau features its Moldlife Sense mold-monitoring system, launched in 2021.

Moldlife Sense sends validated and preset setup parameters to the Gestica machine control. In addition to a digital cycle counter and alignment aid for mold setup, Moldlife Sense features optical monitoring via high-resolution cameras and the ability to record and study tool acoustics as it operates. In addition, the package uses sensors to monitor tool breathing, platen parallelism, cavity surface temperature, plate temperature and tool centering.

An electric Allrounder 720 A will utilize a new size-1300 injection unit to mold thin-walled IML cups as an alternative to deep-draw thermoforming. Arburg says the use of its own AMKmotion servomotors allowed the high injection volumes and precision required. Elsewhere, an Allrounder More 1600 will be molding medical luer-lock connectors, the first application to show part handling with a Yaskawa robot that is communicating with and can be directly programmed via the Gestica control. In addition, an Allrounder Cube 1800 will run an 8+8+8 cavity cube mold from Foboha utilizing that company’s new CITI technology. The three-component cube mold will produce a functional component from PP, TPE and acetal. A six-axis robot handles part removal and overmolding insertion. Finally, the display’s biggest press—a hybrid Allrounder 1120 H with more than 660 tons of clamp force—will mold a tool case.

Arburg will also show products from sister companies, including two 3D printers from innovatiQ. Beyond its own stand and its participation in the VDMA Circular Economy forum, an additional 15 Arburg presses will be spread amongst partner companies throughout the fair.

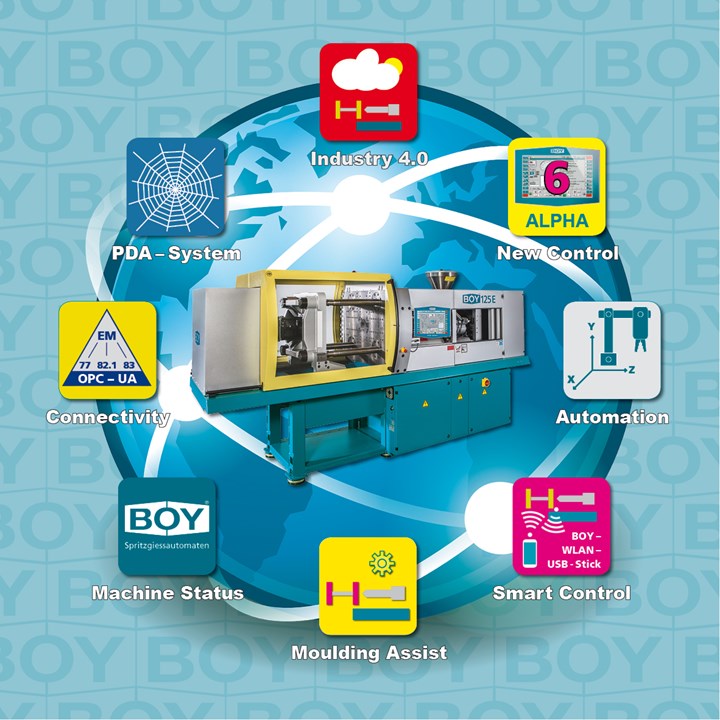

New Control & Digitization Package

In addition to nine injection machines at its booth, Boy’s K fair presence will be augmented by another four machines running at the booths of partner companies. Boy says its exhibits will reflect the broader theme of digitalization, the circular economy and climate protection. The firm will debut the Alpha 6 machine control at the show, featuring a 16:9 screen format as part of its digitalization package. Following the K, Boy says the Alpha 6 will replace the current Procan Alpha 4.

At the heart of Boy’s digitalization package is the new Alpha 6 machine controller to be launched at K 2022. (Photo: Boy Machines)

Also new at K, Boy will present its own cooling-water distribution system, which was developed in-house and will be offered as standard for all its machines going forward. With this system, the set flow rate is digitally recorded and shown on the machine display, while target cooling-medium quantities and process tolerances can be entered, displayed and monitored. A temperature display with process data monitoring is available as an option.

Boy will also showcase an optional electromechanical ejector as a replacement for its hydraulic ejectors. This version offers an independent operating mode with synchronized ejector movement. At the fair, the electric ejector will synchronously move parts to the gripper hand of the LR 5 robot. While the mold opens in the opposite direction, it can be synchronized to the ejector’s movement so that the molded part does not experience any horizontal acceleration when removed from the tool. Boy says the primary advantage of the electric-driven ejector is the possibility of simultaneous operation independent of the machine’s hydraulics.

Boy’s booth will also feature a number of integrated handling devices. The company notes that while its LR 5 has been used up to now mainly for part removal, Boy will show at K that it can offer other functions. To do so, a Boy 35 E VV overmolding machine will overmold metal inserts into T-shaped handles, which are then removed from the mold by the LR 5 and supplied to an automated assembly system. The inserts, which can be individually selected by the show visitor, are inserted into the plastic grip. The LR 5 then places the assembled sets on a conveyor belt and the visitor receives an individualized tool set.

Even More Electrification

Netstal’s Elios 4500, which has switched from a hybrid clamp to all-electric actuation, will make its show premiere at K. By switching to all-electric mold closing, Netstal says the machine’s dry cycle has been accelerated by 0.1 sec, while average power consumption has been reduced by 7 kW and the machine’s overall length has been reduced by 450 mm or roughly 18 in. At the show, the press will mold thinwall 150-ml, IML-decorated 6.5-g yogurt cups from a certified renewable PP supplied by SABIC in a 5-sec cycle. Based on tall oil, which is a byproduct of paper production, the resin reportedly has the same processing properties as conventional PP. The 12-cavity mold and IML automation are supplied by IML Solutions. In addition to using a renewable material, the cups’ in-mold labels from Verstraete will feature Holy Grail 2.0 digital watermarks that ease sorting at end of life.

A second Netstal press will mold pipette tips from a 64-cavity tool from Otto Männer on an all-electric Elion 1200, utilizing high-speed handling supplied by Micro Automation. The pipettes will be molded from an electrically conductive compound supplied by Finnish firm Premix, which notes that in in-vitro diagnostics, electrically conductive compounds enable liquid level detection for accurate analyses. Cycle time will be 5.3 sec, and the Elion press utilizes Netstal’s Smart Operation Control, launched in 2018 for all the company’s machines running aXos controllers. This control features four “smart” buttons, which initiate status transitions in the molding process while allowing other operating elements to be locked to simplify operation for process technicians. Netstal says this control option allows molders to automate, standardize and shorten recurring process steps. Netstal will also highlight its ability to calibrate machines per ISO 17025 requirements. The company became an accredited calibration laboratory at the end of 2021.

Netstal will mold pipette tips from a 64-cavity tool in a conductive compound at K 2022.

(Photo: Netstal)

An OPC-UA Foundation member, Netstal will also highlight the standardized, manufacturer-independent data exchange between machines and other systems. In its booth, Netstal will show complete integration of an MES platform from bfa solutions, temperature-control units from HB-Therm, and hot-runner controls from Gammaflux. Netstal will also participate in the VDMA’s OPC-UA Showcase. All Netstal machines at K, including those on partner stands, will be integrated into the umati app. Launched in 2017 at EMO Hannover fair, umati (universal machine tool interface), allows attendees to scan QR codes on participating equipment and obtain information on the machine, its status, the job in progress and process values in real time via the umati app.

Smart Molding as Standard

Two European machine premiers, as well as new developments within the Haitian Group, will be on tap at the company’s K 2022 booth that will feature five machines, including three from its Zhafir electric line. Haitian will feature its plan to offer intelligent process optimization packages, which are becoming increasingly common within molding as standard features with their presses. Haitian will debut smart functions that include intelligent energy management, intelligent process optimization, plastication efficiency, and clamp-force optimization. Haitian aims to offer smart features as a standard feature at no extra charge.

To showcase flexible integration via standardized interfaces and open systems, several system partners will be integrated into Haitian machines at K. In MES, in addition to its own GoFactory, another unnamed MES partner specifically targeting the European market will be presented, with all five machine exhibits connected to both systems.

Machine exhibits will include an electric Zhafir Zeres Med Series with 122-ton clamp and Haitian’s medical package. It will demonstrate an economical cleanroom setup utilizing a laminar airflow box from German cleanroom equipment provider Max Petek. Also, an electric 305-ton Zhafir Zeres Multi Series featuring an R-version or piggyback-style auxiliary injection unit will mold tape-measure housings from ABS and TPE. The machine will be the center of a production cell utilizing Haitian’s in-house Hilectro robot. A 370-ton hybrid Zhafir Jenius Series will mold an automotive part handled by a Success 33 robot from Sepro, while a two-platen servohydraulic 460-ton Haitian Jupiter will mold a fruit box from HDPE and TetraPak recyclate compound. For packagingr, a servohydraulic Haitian Mars K Series with injection speeds up to 1000 mm/sec will produce an IML food container.

At K 2022, a Zhafir Zeres Multi Series with a piggyback-style auxiliary injection unit will mold tape-measure housings from ABS and TPE. (Photo: Haitian)

Tapping Directly Into Renewable Energy

Wittmann Group’s displays will be spread among its booths in the injection and auxiliary halls, as well as the VDMA Circular Economy Forum. Under the theme “It’s all Wittmann,” Wittmann Battenfeld will present its equipment for the first time in the new Wittmann design, emphasizing itself as a single-source supplier of complete injection molding cells, including machines, automation and auxiliaries, all with the option of Wittmann 4.0 integration.

Beyond running renewably resourced and recycled resins, Wittmann will emphasize sustainability through a patent-pending collaboration with a customer that allows its EcoPower injection molding machine to utilize renewable energy from sources like solar, wind or water directly without first having to pass the renewably derived electricity through inverters, transformers and high-voltage power lines that lead to power loss. In collaboration with its customer WAGO, Wittmann will highlight a conceptual study using a machine from its all-electric EcoPower series demonstrating just such a setup, for which it has jointly applied for a patent with WAGO.

At the show, an EcoPower 180/750+ running direct current will mold an electrical part for WAGO in flame-retardant nylon from a 24-cavity mold. Parts are removed by a modified Wittmann WX142 robot. The DC-version automation is powered directly via the intermediate DC circuit of the EcoPower press, which also returns any excess energy released by axis deceleration to the intermediate circuit. Wittmann notes that this not only enables lower energy costs via direct use of renewable energy like solar power, but direct current can also be stored in conventional batteries, providing molders a method to handle current peaks and valleys. If necessary, the machine can be changed over to AC operation. In addition, Wittmann says the EcoPower 180’s new B8X control enables faster response to sensor signals and higher part reproducibility.

In addition, the company will showcase multicomponent molding in a reusable three-component coffee to-go cup, which also utilizes Cellmould microcellular foam to reduce the amount of material used. Here a lid is molded from Borealis’ renewably sourced Bornewable PP on a servohydraulic SmartPower 400/750H/210S/525L Combimould with rotary unit and mold from Haidlmair. Wittmann notes that a special feature of the mold is the use of hybrid components combining conventionally processed tool steel with 3D-printed “yellow” bronze, which is an alkali copper/tin/zinc cyanide plating system. A clear first shot is overmolded in the second cavity by the Bornewable PP blend paired with Cellmould foaming for insulative properties. The lip is molded in an adjancent cavity from the same material but is colored separately thanks to the Haidlmair tool. All three components of the reusable cup are molded in Bornewable PP, simplifying end-of-life recycling. The parts are deposited on a conveyor belt by a WX142 robot and then packaged, with Bornewable PP also used for packaging.

All three components of the reusable coffee cup molded at K 2022 by Wittmann come from renewable PP with its Cellmould foaming reducing material and adding insulative properties to the cup. (Photo: Wittmann Battenfeld)

Wittmann will present two more applications of renewable materials; in both cases, HiQ Flow software compensates for viscosity fluctuations. A biodegradable ice-cream cup will be molded in six cavities on an EcoPower 110/750 equipped with the new B8X control. Here BAOPAP resin from HopeTree is used. The material consists of water, vegetable oils and fats, starch, vegetable thickening and swelling agents, and natural fibers. Disposable via household composting, the material reportedly biodegrades completely within 50 days. HopeTree positions the bioresin as a substitute for cardboard.

Wittmann says ice-cream cups molded from HopeTree bioresin show how HiQ Flow software can compensate for viscosity fluctuations in biobased materials. (Photo: Wittmann Battenfeld)

The second application applying renewable material will be at the VDMA Circular Economy Forum. Here an EcoPower 110/350 with B8X control and eight-cavity mold will mold a building block from a Fasal Wood GmbH compound. The Austrian company compounds resin from wood flour and post-industrial PP supplied by Borealis. The cell features a Wittmann W918 robot and S-Max 3 screenless granulator in an “Insider” configuration that fits within the machine safety guards. Molded parts and sprue are removed by the robot, with the sprue passed directly to the granulator, where it is ground and then returned to the process. To ensure repeatability, HiQ Metering for active closing of the check valve and HiQ Melt for measuring the material’s melt-flow index are paired with HiQ Flow.

Injection-compression molding (ICM) will be demonstrated on a high-speed EcoPower Xpress 160/1100+. Running a four-cavity mold, the machine will mold a 230-ml cup from Sabic PP with a 0.28-mm wall thickness. An IML system from Beck Automation features automatic positioning of all four labels, supplied by Verstraete. Regardless of its position inside the magazine, each label is placed in the same position on the IML core, reducing reject rates and operator intervention. Quality inspection is performed by an Intravis vision system with 10 cameras integrated in the production line.

A servohydraulic MacroPower1100/12800 will use Wittmann’s Cellmould foam technology to create a door panel consisting of a natural-fiber mat onto which a PP map pocket is overmolded. The precut natural-fiber mats are pulled from a buffer stack and inserted into an IR heating station by a WX152 robot. The heated mats are then placed into the mold on the fixed half, where it is formed, cut to size and overmolded. This press features Wittmann’s new CMS Lite condition-monitoring system, which continuously checks the state of the servohydraulic axes to determine the pump’s and valves’ conditions.

CMS Lite conditioning monitoring will also be on a press from the new SmartPlus series with B8X control, which utilizes servohydraulics plus braking-energy recapture for greater energy efficiency and repeatability. A SmartPlus 90/350 at the center of a Wittmann automation cell will mold spirit or bubble levels from ABS in a 1+1-cavity mold. After top and bottom parts are molded, the top piece is printed at a laser station, while the bottom section is placed on a tray fitted with vials. Next, the two parts are pressed together under a preset force, and the finished levels are transported to a testing station, where the vial’s positioning is checked by a vision system. After inspection, the finished spirit levels are removed and deposited on a conveyor belt by a Wittmann WX138 robot.

In LSR, a servo-hydraulic SmartPower 120/350 LIM will mold four different closing caps in a single process, using a four-cavity mold from Austrian firm Nexus. The Die Nexus X200 metering unit, which is connected with the machine’s B8 control system via Euromap 82.3 OPC-UA protocol, comes with a new Servomix dosing system. The mold, meanwhile, uses the latest Flowset needle-shutoff cold-runner technology. The caps are removed by a Wittmann W918 robot and packaged.

In a second LSR application, a micro loudspeaker’s membrane will be molded from thermoplastic and silicone on a MicroPower15/10H/10H Combimould using a single-cavity tool where more expensive multicavity tooling is more often used. The MicroPower features two-stage screw/plunger injection. The LSR metering pump from EMT Dosiertechnik consists of a 1-liter cartridge for extremely small metering volumes. EMT says continuous emptying of the cartridges ensures high precision while a minimized blending section enables rapid cleaning and minimal material loss during changeover.

In support of lightweighting, Wittmann will showcase its new Airmould 4.0 pressure-control module for gas injection and new manual operating unit.

Furthering energy efficiency, Wittmann says its machines at the show are equipped with the IMAGOxt energy-management software, which provides a scalable display and visualization of energy consumption by connected equipment. The program also calculates CO2 emissions and energy savings that can be documented in reports. This program is available as a web application and optional extension to Wittmann’s TEMI+ MES program or as a standalone.

At its booth, Wittmann also will feature a work cell consisting of a SmartPower 120 and a W918 robot to which its HoloVerse voice control and augmented-reality functions have been added. At that same booth, Wittmann will present a line for decorated and functionalized surfaces, in collaboration with Leonhard Kurz and in-mold decorating (IMD) supplier Syntech Plastics. Showcasing flexibility, the equipment is laid out in a manner that could accommodate IMD with a feeding unit, IMD with film preheating, IMD Vario with preheating and thermoforming, and straight insert molding. Built around a SmartPower 300 machine and W846 robot with special gripper technology, the cell also features IMD components from Kurz, as well as hardening and cleaning technology from Bayer, creating a fully functional conceptual component for an automotive headliner. In addition, the molding machine is equipped with the Wittmann’s Expert-Coining package, which allows parallel mold movements during the injection process.

Outside its own booths, IKV Aachen will use a Wittmann Battenfeld SmartPlus 120/525 machine with B8X control to mold a stackable sorting box. The box is made of colored PP on 100% PCR base material. Here an internal mold -ressure control system developed by IKV will monitor molding of 100% PCR. Finally, the Hungarian Plastics Industry Assn. will feature a SmartPlus 60/210 molding biodegradable coffee capsules from a water-soluble PVA and a biomaterial blend.

Related Content

Exhibitor Registration Opens for K 2025

Exhibitor registration for the triennial event, which will take place Oct. 8-15, 2025, in Düsseldorf, Germany, is open with a reservation deadline of May 31, 2024.

Read MoreK 2022 Additives & Materials: Sustainability in the Lead

Nearly all of the new additives highlighted at the big show are aimed at enhancing recyclability of commodity resins and some volume engineering resins such as nylon and PC. A few new materials, on which we had not previously reported, also surfaced at K 2022.

Read MoreEnergy Efficiency in Focus at K 2022

As much as cycle time, kWh/kg was an oft-cited metric by injection molding machine suppliers at October’s big show.

Read MoreBreaking the Barrier: An Emerging Force in 9-Layer Film Packaging

Hamilton Plastics taps into its 30-plus years of know-how in high-barrier films by bringing novel, custom-engineered, nine-layer structures resulting from the investment in two new lines.

Read MoreRead Next

K 2022 Preview: Injection Molding Closes the Circle, Digitally

Because the market requires sustainability—and important component of which is the circular economy—and sustainability requires digitization, all three will be major themes at injection molding booths at K 2022.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More