Arthur Eichengrün: Pioneer of Cellulose Acetate Manufacturing Processes

Explore the legacy of Arthur Eichengrün, a trailblazer in 20th-century chemistry and materials science, whose achievements reshaped both medicine and the plastics industry. His groundbreaking contributions led to his induction into the prestigious Plastics Hall of Fame in 2024.

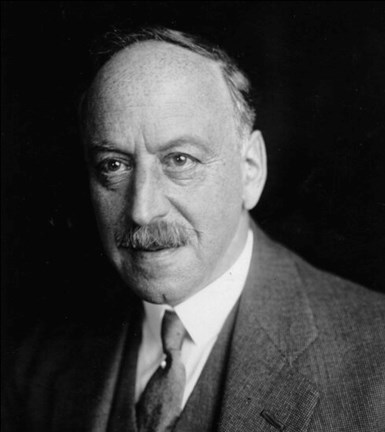

Dr. Arthur Eichengrun, Cellon-Werke (Germany). Source: Plastics Hall of Fame

Arthur Eichengrün, a pioneering figure in chemistry and materials science, left a mark on the scientific landscape of the 20th century. Joining Bayer & Company in 1896, Eichengrün's career saw him trailblazing in pharmaceuticals, plastics and photochemistry.

Among his achievements were the development of Protargol, an anti-gonorrhea medication, and his co-discovery of aspirin, two innovations that revolutionized medicine. However, his contributions extended far beyond the realm of pharmaceuticals.

In 1903, alongside Theodore Becker, he unveiled the first soluble cellulose acetate material, known as Cellit. Their invention not only paved the way for safer and more versatile materials but also played a pivotal role in the development of cellulose acetate film, a significant advancement in cinematography adopted by industry giants like Eastman Kodak and Pathé Frères.

Eichengrün established Cellon-Werke in 1908, where he furthered the science of injection molding by introducing the first injection molding press in 1919. During World War I, Cellon, a flame-resistant plastic developed by Eichengrün, found critical applications in aviation, including pilots’ goggles and gas masks.

He was forced to sell his company in 1933 and later endure imprisonment in the Theresienstadt concentration camp. But, upon liberation in 1945, his unyielding commitment to scientific inquiry led him to resume his scientific pursuits in Berlin, amassing a total of 47 patents throughout his career.

Related Content

-

Breaking News From NPE2024

Here is a firsthand report of news in injection molding, extrusion, blow molding and recycling not previously covered.

-

Real-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

-

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.