Automation Cuts Production Time For LED Lighting Units by 89%

Robot-assisted overmolding helps Swiss company compete with low-wage countries.

Replacing five manual assembly steps with a combination of injection overmolding and robotic insert loading and part removal helped a Swiss manufacturer save almost 90% in production time for automotive LED lighting components.

Founded in 1969, JESA of Villars-sur-Glâne specializes in custom-made ball-bearing solutions. One such product is a dynamic adjustment mechanism for multi-directional LED car headlamps. JESA produces millions of these complex components annually, using a turnkey injection molding cell supplied by ARBURG, Inc. (U.S. office in Rocky Hill, Conn.). The automated cell cut production time from 90 sec with manual assembly to 10 sec, helping ensure JESA’s continued competitiveness in Switzerland against low-wage countries. (The firm also has a plant in China.)

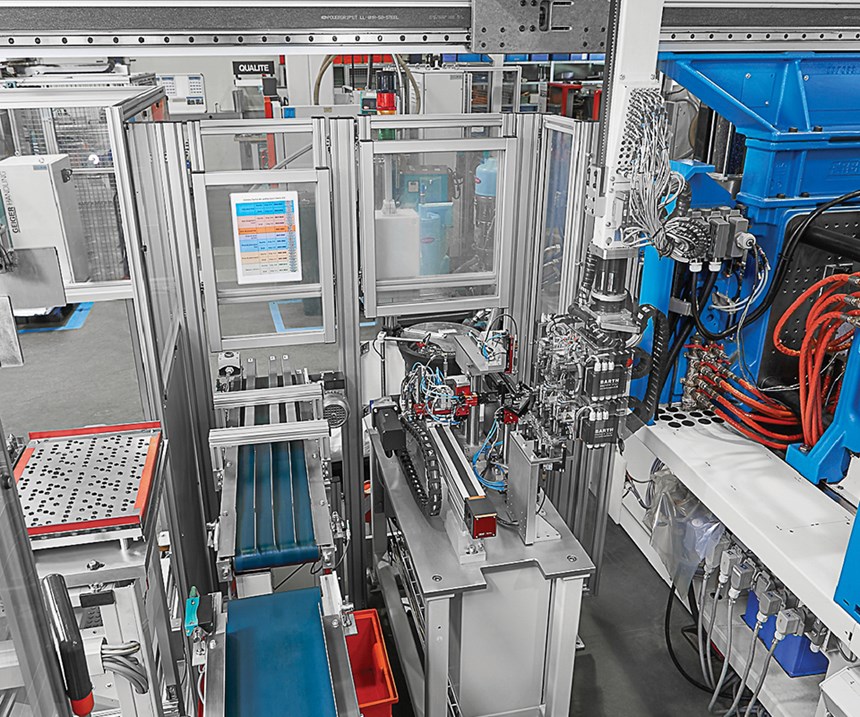

These LED lighting actuators with integral ball bearings are produced in a cell based on an Arburg Allrounder 470 H hybrid press (100 metric tons, servo-electric toggle clamp and screw plastication, hydraulic accumulator injection) and an Arburg Multilift V Cartesian robot. The system also includes a palletizing station and conveyor line from Schuma Maschinenbau GmbH of Germany, a feed and singulation unit from Afag Automation AG of Switzerland, and a complex gripper from Barth Mechanik GmbH of Germany. Arburg sourced, set up, commissioned, and delivered all the components to JESA as a turnkey system.

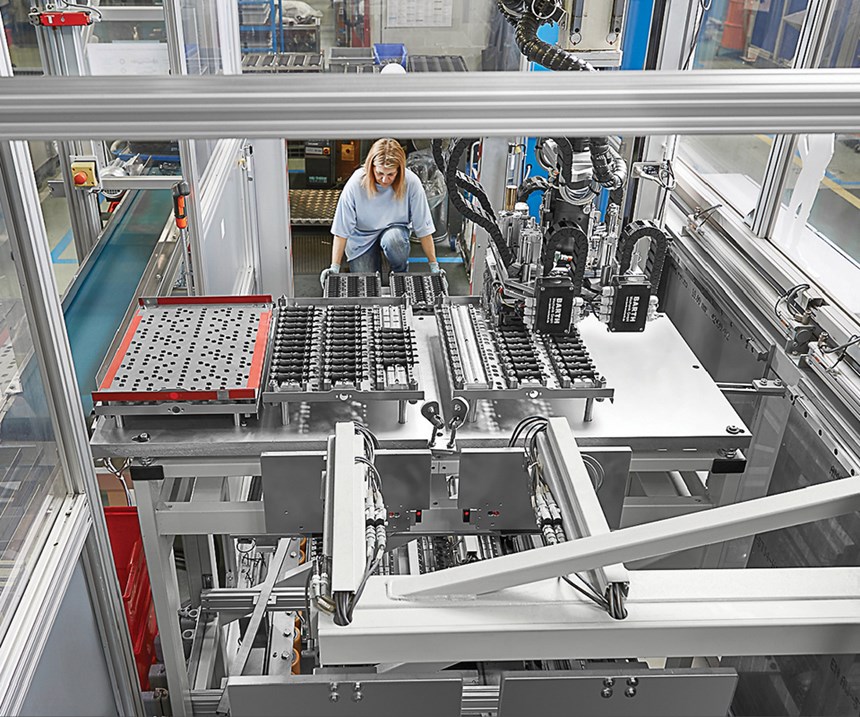

The process starts when the top-loading robot with extended Z-axis picks up four ball-bearing inserts per part at two loading positions (three at one position, one more at the other) using a pneumatic gripper and places them in a four-cavity mold. A total of 16 inserts are thus held in the gripper.

After overmolding with polyetherimide (PEI) engineering resin, the robot demolds the finished parts and sets them down in a metal tray. A conveyor system then channels the transport trolleys with the trays out of the system. Loading the inserts into trays and down- stream visual inspection and storage are the only manual operations.

Related Content

-

AI: The Next Big Thing in Plastics Processing

Discover how artifical intelligence is revolutionizing plastics processing. Hear from industry experts on the future impact of AI on your operations and envision a fully interconnected plant.

-

'Smart,' Moisture-Based Drying Technology Enhanced

At NPE2024, Novatec relaunches DryerGenie with a goal to putting an end to drying based on time.

-

Real-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.