Automotive Plastics: New Thermoplastic Solutions Redefine ‘Performance’ from All Angles

Lightweighting and resistance to heat, chemicals and weathering drive developments in thermoplastics for interiors, exteriors, underhood, powertrain and chassis.

Summarizing recent innovations in thermoplastics for automotive is no small task. Virtually everything that meets one’s eye in a vehicle’s interior is thermoplastic these days, and the same goes for a look under the hood and a good deal of what is visible on the exterior—not to mention innumerable plastic components that don’t meet the eye in powertrain, chassis, and elsewhere. And while much of the conversation about automotive plastics dwells on lightweighting for fuel efficiency, there are many other performance requirements that drive materials developments, such as resistance to fuels and chemicals, heat, wear, sunlight, and weather. In other cases, the goal is improved process- ability to enhance quality and reduce manufacturing cost.

We asked key materials suppliers (not all of whom responded) that have been among the leaders in the development of automotive applications to weigh in on what they see as the areas of an automobile experiencing the most dramatic developments in thermoplastic materials offerings.

Jeffrey Helms, global automotive OEM corporate accounts director at Celanese Engineered Materials, Irving, Texas, exemplifies others’ responses in noting that vehicle fuel economy and CO2 emission targets are the two biggest drivers and challenges in the global auto- motive market. Driving materials developments are hotter under-hood temperatures associated with downsized and turbocharged internal combustion engines, and an increase in electrification with a corresponding need to reduce vehicle mass to increase vehicle range. “Each of these is driving the need for material advances in thermoplastics. Cost-effective metal replacement for component and vehicle structures are creating increases in demand for thermoplastic composites and engineering thermoplastics along with processing methods to enable large-scale production capability. Higher underhood temperatures are driving highly engineered plastics to provide the durability that consumers demand.”

Helms also sees increasing demand for power electronics in both vehicle interior and exterior. “You can imagine these systems will continue to grow as more active safety systems are incorporated, culminating in a growing fleet of autonomous and semiautonomous vehicles” He notes that Celanese is working with both OEMs and component suppliers to help them manage heat dissipation in these devices while minimizing the added part weight and cost.

Mike Chiandussi, powertrain market segment specialist at BASF Corporation - Engineering Plastics, Florham Park, N.J., notes that powertrain and chassis account for more than 50% of the total weight of the vehicle. “It’s logical to take mass out of the largest pieces of the pie per se.” He notes that thermoplastics allow one to achieve complex geometries and design while driving weight out of the vehicle. But He also identifies technical challenges such as high-operating temperatures and chemical wear.

LANXESS Corporation, Pittsburgh, sees OEMs targeting improvements in the powertrain, aerodynamics, and overall weight to meet global fuel-efficiency regulations. With the introduction of more small, turbo-charged engines and exhaust-recovery systems, the demand is for materials that can withstand higher engine operating temperatures in a smaller space. Cooling systems also are operating at high temperatures, explains, Jose Chirino, Americas technical director at Lanxess’ high-performance materials business unit. Adds BASF’s Chiandussi, “We predict that about 20% of all turbocharger applications will require a high-heat- resistant plastic as engine temperatures increase.”

Solvay Specialty Polymers, Alpharetta, Ga., has focused on three areas for its polymers, according to global automotive business-development manager Brian Baleno: transmissions, where the need is for thermally stable, wear-resistant materials; lightweighting; and electrification of the drivetrain.

Jerry Mazur, new business development manager for automotive at Trinseo, Berwin, Pa., views semi-structural applications as the most dramatic development. “Lighter, safer and environmentally sustainable vehicles are a priority, and cost savings is a primary target for manufacturers. It’s in this space that innovative materials and their applications are replacing previous technologies.”

HEAT, CHEMICAL & WEAR RESISTANCE

As underhood temperatures rise, suppliers are offering more heat- resistant products, often with an added lightweight advantage. The new Fortron flexible PPS by Celanese has enabled significant weight reductions in underhood applications while resisting extreme temperatures (>75% tensile strength retention after 1000 hr at 175 C/347 F). Helms notes that because nylon absorbs moisture and undergoes variable performance in rising temperatures, parts manufacturers and OEMs will look to PPS due to its chemical resistance and long-term high-temperature performance stability under the hood and in applications such as EDS (electrical distribution system) fasteners. China’s Chinaust utilized Flexible Fortron PPS to blow mold and thermoform a positive crankcase ventilation (PCV) tube that is now in production on three GM car platforms. The material reduced part count by 50%, saved over $3/car per car, and consolidated a metal-and-plastic assembly into one plastic unit.

Lanxess has responded to these needs with Durethan XTS series, its latest generation of high-heat-resistant nylon 6 grades, as well as the Durethan HR line of high-temperature hydrolysis-resistant nylon 66 for cooling systems. Chirino sees further opportunities for high-tech plastics in battery systems (housing/carrier, cell holder, battery management systems, connectors), engines (bracket, rotor, connectors, cooling circuit), and power electric (housing, power electronics, and connectors). He adds that newer designs for oil-pan modules are rejecting nylon 66 in favor of equally robust but economical nylon 6. The latest example is the module for the new six-cylinder Boxter engines of the Porsche 911 Carrera, which is made with Durethan BKV 30 H2.0.

BASF’s Chiandussi says the company’s Ultramid Endure high-heat-resistant nylon 66 portfolio can be used in turbocharged air-induction systems, including the air-intake manifold, charge-air

ducts, resonators, intercooler end caps, and throttle bodies. It can also achieve long-term-service temperatures of 220 C/428 F and withstand peak temperatures of 240 C/464 F.

Two new powertrain applications, which debuted on the 2017 Alfa Romeo Giulia’s 2.0L GME engine, utilize BASF’s high-heat nylon: The air-intake manifold with integrated charge-air cooler is made with Ultramid Endure D3G7, a 35% glass-filled nylon 66 that is replacing less thermally stable versions of nylons 6 and 66. And the hot-side turbo duct is made with Ultramid Endure D5G3 BM, a 15% glass-filled nylon 66 that is replacing metals in turbo ducts.

Higher temperatures and more demanding wear requirements for transmissions are fueling the need for heat-stable and more wear-resistant materials including Torlon PAI and KetaSpire PEEK, says Solvay’s Baleno. Three key applications in transmissions that demand high- temperature and wear resistance are seal rings, thrust washers, and thrust bearings. Thrust bearings of PAI and PEEK now used to replace axial needle bearings can save 2.5 mm/0.098 in. per bearing. This spatial savings enables designers to downsize aluminum housings and achieve significant weight savings.

Torlon PAI is known for maintaining strength, stiffness, and toughness at high temperature. Its claim to fame is wear resistance in both lubricated and dry environments. Some grades specially formulated for wear resistance include ones with PTFE and graphite, carbon fiber, and carbon fiber plus PTFE. KetaSpire PEEK reportedly offers better fatigue and wear resistance, higher impact strength and higher ductility than other commercial PEEK products.

Wear-resistant grades used in powertrain components include carbon fiber or graphite with PTFE.

Celanese’s CoolPoly thermally conductive plastics, which comes in electrically conductive and insulative grades, have taken hold in automotive heat sinks by matching thermal properties of aluminum while offering weight and cost savings. These plastics enable 40-55% mass savings due to reduced density and design optimization. A commercial use is in the Ford Mondeo lighting module, where replacing die cast aluminum saved 54% in weight. CoolPoly is also being evaluated for metal replacement in power electronics and lighting.

For underhood parts such as radiator air fans, the leading producer of styrene-maleic anhydride (SMA) copolymers. The Netherlands’ Polyscope (U.S. office in Novi, Mich.), is developing highly glass-filled SMA/nylon blends to address water-absorption issues of nylons and replace over-engineered nylons, according to CEO Patrick Muezers.

Houston-based SABIC sees PP making its way into underhood applications. Scott Fallon, global leader of SABIC’s automotive business, points to the 2016 SPE Automotive Innovation Award powertrain winner: the air-intake manifold in VW’s 2015 EA21 1.6L engines, said to be the first such part launched in China using 35% glass-reinforced PP to replace nylon 66. The part provides a 25-30% cost reduction and 15-20% weight reduction while retaining properties and improving weld strength. SABIC’s G3135X PP in this part utilizes finer glass fibers and special sizing.

AESTHETICS, AERODYNAMICS & STRUCTURAL PROPERTIES

Automotive interiors is one key focus for A. Schulman, Inc., Fairlawn, Ohio., says Frank Roederer, senior v.p. & general manager for North America. He and his European counterpart Heinrick Lingnau, point to the growth of touchscreen technologies that demand specialized plastics and the demand for more plastic parts with look and feel of natural materials.

The firm’s high-flow, low-emissions Schulablend M/MK ABS/ nylon and M/MW ASA/nylon and other alloys offer the potential to eliminate painting and achieve a consistent low-gloss/matte finish. Available in UV-stabilized custom colors and low gloss, they are found in trim such as loudspeaker grilles, pillar covers, instrument panels (masks, end caps, HVAC bezels), trunk and window frames, seat side shields and AV system bezels.

Roederer also highlights softer flexible materials like Polyvin PVC and Invision TPEs for decorative trim like door and console armrests, shifter knobs, bin liners, and cup holders, which need a dry-to-the- touch and non-tacky feel. Polyfort filled, unfilled, and impact-modified PP in UV-stabilized custom colors also get play in pillar covers, door and instrument-panel components, and rear-quarter trim panels.

Lingnau also notes the higher-quality appearance trend in exteriors, where Schulman’s fully compounded compounds are replacing painted parts in metallic colors. The company provides silver metallic compounds by using special pigments and mineral fillers to achieve metallic optics without weld lines and injection marks. This earned the company the 2016 Grand Innovation Award of SPE Europe for the Mercedes Benz GLA skid plate for front and rear bumpers, produced with Polyfort FIPP 10 T K2369, a silver-metallic, impact-modified PP compound using an innovative filler system.

Meanwhile, car makers are striving to make premium inte- riors affordable, says Trinseo’s Mazur. They want surfaces to have a high-quality look and feel, to be durable and less expensive to manufacture in order to pass savings on to customers. This is why the OEMs have stringent requirements for plastics with aesthetics and haptics and best-in-class scratch resistance, along with good processability and cost-effectiveness.

Trinseo focuses its Velvex family of factory-colored TPOs with glass reinforcement for interior applications. “With these products, we bridge the gap between technical and aesthetic performance, and we’re doing so at an affordable cost,” says Mazur. These materials boast improved soft touch, outstanding scratch resistance, and low gloss while meeting key requirements of cost-efficiency. These materials reportedly offer a superior finish for unpainted parts such as door panels.

Trinseo has also developed lower-density Pulse PC/ABS products that not only enable less weight and cost in parts, but also offer low gloss, easy flow, faster cycles, high impact strength at low temperatures, heat resistance optimized for the majority of interior auto components, and low odor and VOCs. For example, Pulse GX50 is approved by BMW for UV and hydrolytic stability and is used on the BMW 1 series, i3 and i8.

Mark Minnichelli, director of technical development at BASF’s performance materials division, points to Ford’s new Lincoln Continental, which features an innovative seating architecture. With its 35% glass-filled, impact resistant Ultramid nylon 6, BASF contributed a 20% weight reduction for the front-row seat pan vs. the metal predecessor, and 15% cost savings.

Minnichelli also heralds the use of a 20% carbon-fiber reinforced Ultramid nylon 66 to produce the grille-opening reinforcement (GOR) on the 2016 Ford Shelby GT359 Mustang. Not only 2.5 lb lighter than the traditional GOR of metal stampings overmolded with plastic, but the new part’s aesthetic quality prompted Ford to forgo the “beauty cover” to hide the GOR, saving another 1.9 lb for a 45% weight reduction overall.

Meanwhile, Polyscope’s main focus is on interior structural parts. Says Muezers,“We are aiming to achieve performance properties that bridge the gap between nylon 6 and nylon 66 in applications such as instrument-panel supports, structural consoles, audio components, and interior trim.” Since 2013, its Xiran IZ terpolymers—based on SMA and N-phenylmaleimide, have made significant commercial strides with several OEMs in sunroof frames. Applications such as this require a high degree of functional integration, high-precision molding, and greater stiffness. Xiran products replace glass-filled PBT/ASA blends, which can have warpage issues, cost more, and are more difficult to process.

Polyscope is also targeting instrument-panel carriers where SMA can meet a broader temperature range (-35 C to 120 C or 31-248 F) than the widely used PP. In particular, PP does not have comparable low- temperature performance, which is important for airbag deployment.

At the K 2016 show in Dusseldorf, Ineos Styrolution, Aurora, Ill., launched what are believed to be the first styrenic thermoplastic composites, with mechanical properties that reportedly exceed composites of nylon 6 or PC. Its StyLight composites are based on a modified SAN with glass or carbon-fiber fabrics for structural and aesthetic/semi-structural applications in interior and exterior panels, seat structures, door modules, center consoles, tail-gates, and parts with a carbon-fiber look. StyLight grades are offered as semifinished goods or thermoplastic sheets, which are ready for processing via thermoforming and overmolding. The company has been in talks with several car makers and, in cooperation with German engineering company KTM Technologies, has developed a selection of concept studies of StyLight in exterior and interior applications like body panels, tailgates, door modules, and consoles.

Celanese has continued to reduce volatile emissions in interiors with a novel family of acetals that boast formaldehyde emission levels as low as 2 ppm. These Hostaform XAP2 grades reportedly are now the benchmark for acetals in vehicle interiors. They are used in locks, head-rest guide sleeves, HVAC components, buttons, speaker grills, etc. Speaker grills represent a fairly large interior acetal part where its contribution to interior emissions is more heavily weighted. Celanese is continuing to push emission levels down with a next-generation XAP3 acetal line that promises formaldehyde emissions of 1 ppm.

In the area of aerodynamics, active grill shutters play a role in increasing fuel efficiency by as much as 1.1 mpg, but weight and warpage can be an issue. To address this, Lanxess’ new Durethan XF (Xtreme Flow) easy-flowing nylon 6 is being evaluated for reduced warpage and improved cycle times.

LIGHTWEIGHTING ALL AROUND

Lanxess’ Chirino says these XF grades are also gaining applications in structural parts such as front ends, lightweight cross-car beams, rear bumpers, and door modules—thanks to the high-modulus/high-flow materials like Durethan BKV 60 XF, a 60% glass-filled nylon 6 that facilitates complex, thinwall, lightweight applications that replace metal with weight reductions up to 50%.

Solvay’s lightweighting material developments include Amodel PPA and Omnix HPP high-performance nylon with 30-60% long fiber. They are aimed at gears used in EGR (exhaust gas recirculation) and ETC (electronic throttle control), as well as structural parts on the interior panels and consoles and components in chassis systems.

Solvay also reports interest in Tegracore PPSU foam, a novel high- temperature structural and insulating material based on Solvay’s Radel PPSU, for thermal insulation of the electrified powertrain and engine encapsulation, says Baleno. A key feature is its thermoforming capability, which enables foam shapes to be customized.

A. Schulman’s Lingnau cites compounds based on innovative reinforcements (such as micro or nano fillers) and polymer alloys that have lower density but the same performance profile as conventional compounds. “We have alternatives as drop-in products with 8-16% lower specific density, which is a big step forward.” Such compounds include Polyfort impact-modified PP with nano filler, which can be further optimized for weight reduction by adding glass spheres. He also cited the Shulamid nylon family aimed at lightweighting. Its reduced-density RD nylon 6 and RD nylon 66 grades are available with standard 15% and 30% glass fiber. Reduced-density PP compounds are also now available, based on minerals with reduced density and/or hollow glass bubbles.

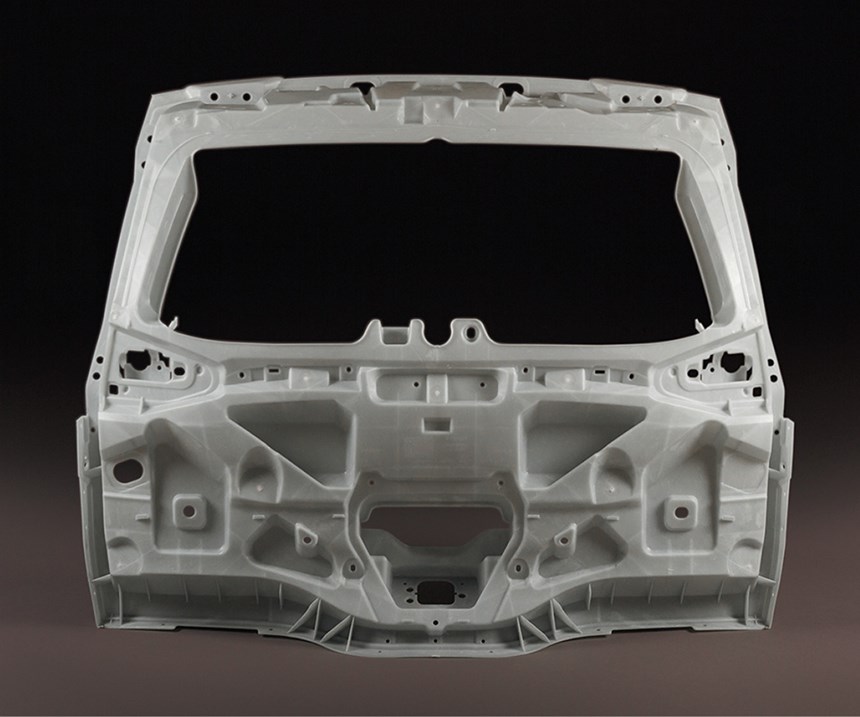

SABIC sees demand for Stamax long-glass PP (LGF-PP) to replace metal in structural applications like front-end modules, door modules, inner tailgate components, and instrument panels. Up to 50% in weight savings are possible, with high stiffness and dimensional stability. Stamax LGF-PP has allowed an Asian auto- maker to shave 30% in weight from the inner tailgate of a recently launched car. “Lightweight tailgate construction is an area of focus for us. SABIC is engaged in multiple projects on all-plastic tailgate designs and we have a full portfolio of solutions for all tailgate components—from the inner structure and outer skin panel to the window. Building on the validated uses of thermoplastics in tailgate components and in glazing, an all-plastic tailgate with a PC-based backlite presents significant opportunity for the industry. A car maker can save up to 30% or 12.5 kg (27.5 lb), depending on the size and design of the entire tailgate,” says Fallon.

Trinseo’s Majur notes that his company has worked with long-standing partner Renault to convert semi-structural parts to LGF-PP. With the fourth generation of the Renault Clio, launched in 2012, Renault reached its target of reducing the lift-gate weight by about 15%, and the effort continues. Front-end modules and air-flow systems, door modules, IPs, center consoles, under-vehicle belly pans, and seat structures are other potential opportunities. Majur adds that LGF concentrates enable improved-cost efficiency and improved manufacturing flexibility vs. fully formulated LGF grades by allowing addition in varying amounts to unfilled PP at the injection molding machine.

PlastiComp, Inc., Winona, Minn., is targeting structural parts for its long-carbon-fiber (LCF) thermoplastic compounds and its unique hybrids of LGF and LCF in a unified pellet—currently available in nylon 66, PP, and TPU—says business-development manager Steve Ouendag. The company is working with several Tier 1 suppliers on metal replacement in underhood and powertrain assemblies with LCF-PP and nylon. Weight savings as high as 50% can be achieved when replacing aluminum or cast metals.

Related Content

Foam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

Read MorePlastics Technology Year in Review: Your Favorite Reads of 2024

A year-end review of the top stories showcasing industry trends, advancements and expert insights. Revisit the articles that captured the attention of the plastics community.

Read MoreGet Color Changes Right In Extrusion Blow Molding

Follow these best practices to minimize loss of time, material and labor during color changes in molding containers from bottles to jerrycans. The authors explore what this means for each step of the process, from raw-material infeed to handling and reprocessing tails and trim.

Read MoreProcessing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More