Avoid Those Devilish ‘Angel Hairs’

Angel hairs wreak havoc on plastics processing: clogging filters, plugging conveying lines, causing feed problems at the blender, and jamming up machine throats. Here's how to prevent their formation.

EDITOR'S NOTE: With this article we begin a series on materials conveying, drying, and blending by Chuck Thiele, who has spent more than 45 years solving processor’s problems in these and other areas related to auxiliary equipment.

Angel hairs … those fuzzy, fitful, filmy pieces of plastic that drive us crazy. Perhaps “snake skins” is a more appropriate name for them, because there is nothing angelic about them. Angel hairs wreak havoc on plastics processing: clogging filters, plugging conveying lines, causing feed problems at the blender, and jamming up machine throats.

To get rid of these nettlesome things—no, to stop them from forming in the first place—starts with finding out where they originate. The one-word answer is elbows. For more than 50 years, long-radius elbows have been used to change direction of flow in pneumatic conveying systems. The radius of these elbows is normally about 8 to 10 times the conveying pipe diameter. A 2-in. pipe system, for instance, would have a 16- to 20-in. radius bend, while a 4-in. system would have 32- to 40-in. radius bend.

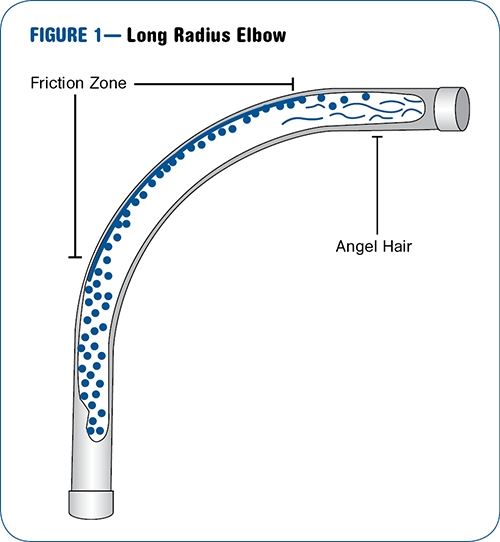

As plastic pellets enter a long-radius elbow, they impact and slide along the wall, passing through what can best be described as a “friction zone” (see Fig. 1). The frictional heat created as the material enters and scrapes along the internal surface of the friction zone causes soft materials like polyethylene and polypropylene to rub and flake off, much like a soft wax or crayon.

The pieces of melted plastic adhere to the walls of the elbow and build up, creating long hair-like strands, hence the name angel hair. These filmy strands, sometime 3 to 4 ft long, ultimately flake off and are conveyed through the system, creating those handling and processing headaches we know so well.

SLOW IT DOWN

Excessive conveying velocity—the speed of air moving through the pipe or tube—can make matters worse, causing angel hairs to form not only at the elbow but even in straight runs of conveying tubing. The ideal average velocity when conveying PE or PP is in the range of 4000 ft/min. In a vacuum conveying system the velocity increases as the air expands and moves towards the vacuum source. The result of this air expansion is a terminal velocity that can be around 5000 to 6000 ft/min. That’s 65 mph.

Systems must be designed to convey the material to the farthest point, and pumps must be sized to maintain the minimum velocity while overcoming the pressure drop of the system. The pressure drop, which is expressed in inches of mercury (in. Hg) in a vacuum system, can best be defined as the energy required to transport the material from its entry point to the use point, plus the static vacuum, which is the energy required to move the air from its entry point to the vacuum pump. The static vacuum can be a critical part of the calculation, especially when vacuum pumps are located hundreds of feet from the material destination points. In this situation you may end up using more vacuum to move the air than the material. Increasing the diameter of the vacuum line is a way to reduce the pressure drop and use the available energy to move material, not air.

Long, straight tubing runs, where the air velocity, and hence material velocity, is increasing can also compound the problem. This is how the problem of angel hair in straight runs actually occurs.

In addition, vacuum systems often have to serve numerous destinations, some close to and others a long distance from the pickup point. When conveying to the farthest distance, the vacuum may be 12 in. Hg, and only 6 in. when conveying to the closer destinations.

The vacuum pump is normally equipped with sheaves sized to operate it at a constant speed. The constant speed creates an air inlet to satisfy the 12-in. Hg requirement. The air flow will be greater when the system is only operating at 6 in. Hg, thus increasing the conveying velocity and exacerbating the problem. In systems with multiple destinations you will have continuous velocity fluctuations. The higher the velocity, the greater the tendency to create angel hair.

In pressure conveying systems, the air is pushed, not pulled, through the conveying lines. The temperature rise caused by the heat of compressing the air exiting the pressure blower can compound the angel-hair problem. It is not uncommon for the temperature differential across the blower to be 12 to 14° F/psi. Thus, if the system pressure is 10 psi, the temperature rise might be as much as 140° F over ambient. This hot air can cause softening of the material, creating problems in rotary feeders and in straight pipes and elbows alike.

The temperature situation is even more acute with vacuum/pressure systems using a single blower. The single blower is an economical solution for railroad hopper-car unloading, but it can create real problems, as the differential pressure across the single blower is a combination of both the vacuum and pressure sides of the system. If a system is operating at 12-in. Hg on the vacuum side and 8 psi on the pressure side, the combination of the two brings a pressure differential of 14 psi. With these conditions, you will have a temperature rise at the pump discharge approaching 200° F.

Truck unloading systems are another problem. Operators like to empty the truck quickly, which means running the truck blower at up to 15 psi. That high pressure creates to a lot of hot air. It is next to impossible to integrate after-coolers into truck unloading systems, so the only solution is to get the operator to keep the pressure well under 10 psi. Good luck with that!

SOLVING THE PROBLEM

In the late 1960s, some suppliers developed “rifled” or “shot-peened” elbows to solve the frictional factor that causes angel hairs. Both of these solutions create a rough internal finish on the elbow that causes the pellets to tumble rather than slide along the walls. The trouble was that these rough interior elbows did not (and still don’t) mitigate the frictional factor at all. The tumbling tends to break up the long strands, just creating more and smaller pieces of angel hair, which compounds the problem rather than solving it.

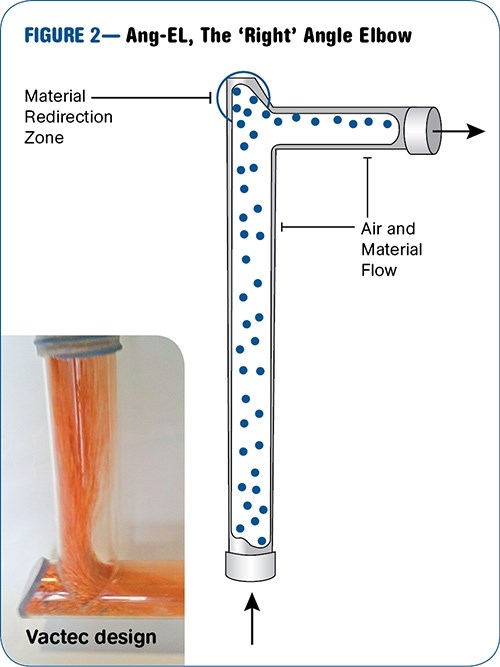

Probably the surest way to reduce the formation of angel hair in either a vacuum or pressure system is to eliminate altogether the radius elbows and the associated frictional factor. Suppliers such as Pelletron, Hammertek, Coperion, and Vactec all have bends that are effective (see Fig. 2). These products are all “right-angle” designs that use varying methods to change direction, while eliminating the friction zone that is present in a radius bend. Critical to each is the capability to accomplish the change in direction without drastically affecting the pressure drop of the system.

There are a number of other techniques processors can deploy to deal with angel hairs. Among them:

•Cool the air. Use an after-cooler for all pressure-conveying systems. You can also modify single-blower vacuum/pressure systems by adding a separate pressure blower for the pressure side, eliminating the combined pressure of the vacuum and pressure side of the system. Be sure to consult with a knowledgeable expert when selecting a pump for the pressure side of the system.

•Manage velocity: This is very important when laying out a new system. Using a variable-frequency drive (VFD) on the pump can help you to tune the system. Novatec (novatec.com), has introduced some interesting technologies that can actually lower terminal velocities and self-modulate for conveying over short or long distances.

•Set a trap: Angel-hair traps can be used to catch angel hair before it clogs a filter, feeder, or machine feed throat. There are two types—those that are inserted directly in the silo or surge-bin suction box, and those that are inserted in the conveying line. Both are available from most suppliers and are fairly effective at capturing angel hair, but they do not eliminate the problem. Angel-hair traps must be cleaned regularly or they can plug and seriously impact the system’s efficiency, creating material discharge or pressure-drop problems.

Related Content

Conveying System is AI-Driven

NPE2024: New system creates and maintains optimal source-to-destination material flows.

Read MoreFinding Efficiencies in How Components Work Together

Auxiliary systems are vital to the proper functioning of a plastic processing line, and they can be a source of major cost and efficiency improvements.

Read MoreDeflection Elbows Eliminate Streamers for Large Film Processor

New elbows eliminate troublesome streamers to increase productivity at leading blown film processor.

Read MoreCut Loading Time Through Direct Charge Blending

Direct charge blender loading, a vacuum-powered automation process, can dramatically improve loading time and reduce material costs. In this article, we address ten common questions to help you determine if the systems are right for your facility.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More