Conveying System is AI-Driven

NPE2024: New system creates and maintains optimal source-to-destination material flows.

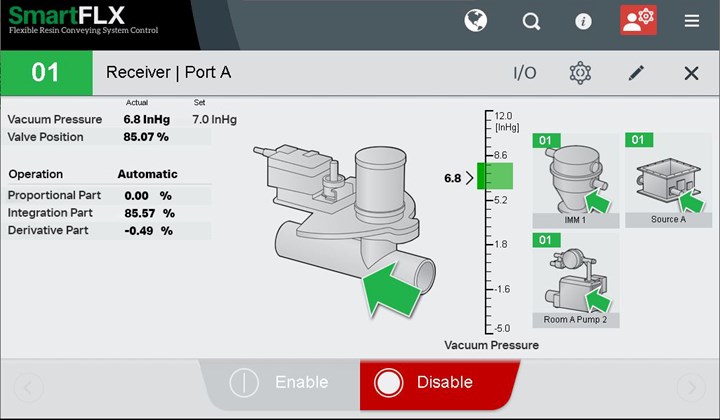

Among the products on display at Conair is a live, interactive demonstration of a novel and patented AI-driven conveying technology that virtually eliminates the need for human interaction or adjustments to central conveying system.

As Conair explains, this patented AI technology creates and maintains optimal source-to-destination material flows regardless of material characteristics, distances or destinations, while automatically compensating for common conveying problems. All the operator needs to do is tell the conveying controller where to send the material and the technology takes care of the rest.

Conair says the AI-driven conveying technology offers processors “a practical, affordable and technically advanced way to meet high labor training and turnover costs head-on. Investing in this product is going to directly save labor and simplify training because artificial intelligence will not only optimize the process of conveying but also will eliminate labor costs, specifically the need for error-prone manual interactions with the conveying equipment.”

Related Content

-

Cut Loading Time Through Direct Charge Blending

Direct charge blender loading, a vacuum-powered automation process, can dramatically improve loading time and reduce material costs. In this article, we address ten common questions to help you determine if the systems are right for your facility.

-

New Pump Rewrites Conveying Rules

NPE2024: Smart Pump technology brings more flexibility and finesse to resin conveying.

-

Automated Resin Management and Blending System for Tight Spaces

NPE2024: Designed for new and existing operations with up to 10 machines and limited available space.