BLOW MOLDING AT NPE: Energy Savings, Lightweighting & Flexibility

New machines are mostly all-electric, hybrid, or servo-hydraulic.

Only a handful of blow molding machinery OEMs provided advance word on their exhibits at the show (March 23-27 at the Orange County Convention Center in Orlando,

Fla.). But their new models amplify recent trends: energy-saving all-electric, hybrid, and servo-hydraulic presses; more sophisticated wheels; smaller stretch-blow machines for custom PET bottles, and ever-higher outputs for soft drinks and water bottles. For the latter, a whole new concept will be introduced that offers greater lightweighting than ever before. There was also news in blow molding auxiliaries and software for process simulation.

ALL-ELECTRICS HUM

Bekum America Corp. will introduce its U.S.-manufactured, all-electric EBlow 607D double-shuttle machine. It is the largest of five models in the EBlow 07 series, launched in 2010. With a mold width of 700 mm, mold daylight of 380 mm, and closing force of 27 tons, this machine can produce bottles up to large handleware with extensive flash-removal requirements.

Like the HyBlow hydraulic version of this machine, its C-frame clamp isolates mold guidance from the closing forces, providing precise guidance and high tonnage with uniform clamp-force distribution, leading to extended mold life. The direct-acting clamp provides variable stroke capability without the complexities of toggles.

NPE will also be the U.S. debut of the new KBB60D double-sided machine, part of a new all-electric series introduced at K 2013 in Dusseldorf (see Feb. ’14 show report). They boast energy savings plus fast cycles, quick mold changes, and the latest hygiene requirements for cosmetic and food containers. The machine at the show (on its way to Currier Plastics, Auburn, N.Y.) will be producing 24-ml hotel amenity bottles in a 2 x 13-head configuration.

Kautex’s U.S. office represents the Italian company Meccanoplastica srl, which will present its line of all-electric injection-blow and stretch-blow molding machinery. Its Jet120 three-station injection-blow machine will operate at the show.

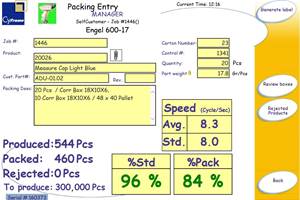

Also present in Kautex’s booth will be Includis Inc., a German software company (with a U.S. branch in Akron, us.includis.com) specializing in web-based manufacturing execution systems (MES) for monitoring production, process data, and energy consumption of plastics machinery.

Another injection-blow exhibit will be of Milacron’s Uniloy UIB 199-3 hybrid machine (electric screw plastication, hydraulic clamp and injection) running a tablet bottle.

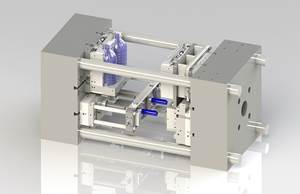

MORE SOPHISTICATED WHEELS

The new MVP rotary wheel extrusion blow molder from Graham Engineering Corp. will see its commercial launch at the show. This latest generation of the firm’s flagship wheel technology features an all-new modular clamp design and a variable-pitch option. These innovations are said to allow a range of package sizes to be blown on a single machine, as will be demonstrated live at the show. The modular clamp also enables offline maintenance, repair, or replacement of a single clamp station to minimize downtime. It’s also available on Graham’s High Speed wheel model.

PET MACHINES FOR CUSTOM & COMMODITY BOTTLES

Three one-step rotary injection-stretch-blow (ISBM) machines will be running in the Nissei ASB Co. booth. One is the ASB-12M, a small machine with 14-metric-ton preform clamp, capable of running a wide variety of resins and bottles or jars. Introduced at K 2013, it uses two servo-driven hydraulic pumps to cut energy consumption by about 40% vs. a comparable standard hydraulic model, and also reduces noise and vibration. It can mold jars with up to 83-mm necks and accepts molds for ASB-12N/10 and ASB-50MBv3 machines. At NPE, it will mold 20-oz reusable sports bottles of Eastman’s Tritan copolyester.

Also running in the booth will be two upgraded versions of Nissei’s best-selling ASB-70 series medium-sized machine. An improved ASB-70DPHv4 will mold super-lightweight 12-oz, 20-g wide-mouth jars in five cavities with inline inspection and packaging. And a brand-new ASB-70DPWv4 with three servo-driven pumps reduces energy consumption about 60% vs. the v3 model.

SIPA of Italy will show off the SIPA T80, a four-station rotary one-step ISBM developed by Automa, which SIPA acquired last year (see January Starting Up). It’s designed for smaller volume production than SIPA’s own units, the newest of which is the Sincro Xtreme system, which joins SIPA’s Xtreme high-speed, continuous, rotary injection-compression molding system (introduced at K 2013) with a rotary high-speed stretch-blow unit (see January Keeping Up). This compact and flexible system is described as the world’s first injection-compression-stretch-blow molding (ICSBM) system. Injection-compression molded preforms are said to be 10% lighter than even the lightest preforms made by conventional injection molding. SIPA will hold seminars on this technology on March 25 and 26.

TRIMMERS & LEAK TESTERS

In blow molding downstream auxiliaries, M.C. Molds, Inc. will present its DST 2000 spin trimmer with a conveyor and new controls allowing for faster setups and greater accuracy.

Minatech Inc. will bring several new machines to the show:

• Star-wheel, servo-driven leak-test and weighing system;

• Leak testers for round containers with multiple necks;

• Take-out and leak-test line for stretch-blow machines;

• Take-out, deflash, and leak-test line for accumulator-head machines producing large parts;

• A similar cell with robot and weighing function for accumulator blow molding of tight-head drums.

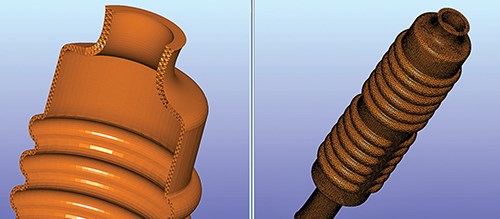

PROCESS SIMULATION GOES 3D

The latest generation of blow molding simulation software from Accuform s.r.o. in the Czech Republic will be presented by its U.S. agent, Compuplast International Inc. The news is that this B-SIM 3D software, which simulates the parison inflation to determine final thickness at every point in the product, now uses fully 3D parison geometry. Prior to this, blow molding simulation often used a “mid-plane” type of assumption for the parison, which was less accurate for parts with relatively small diameters and thick walls. The 3D version is said to show improved correlation with real parts in preliminary evaluations by customers.

See also this month’s Keeping Up section for news in blow molding controls from Eurotherm and R&B Plastics Machinery.

Related Content

At NPE, Cypet to Show Latest Achievements in Large PET Containers

Maker of one-stage ISBM machines will show off new sizes and styles of handled and stackable PET containers, including novel interlocking products.

Read MoreHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

Read MoreUse Interactive Production Scheduling to Improve Your Plant's Efficiencies

When evaluating ERP solutions, consider the power of interactive production scheduling to effectively plan and allocate primary and secondary equipment, materials and resources on the overall production capacity of the business and conclude that this is a key area that cannot be overlooked.

Read MoreMultilayer Solutions to Challenges in Blow Molding with PCR

For extrusion blow molders, challenges of price and availability of postconsumer recycled resins can be addressed with a variety of multilayer technologies, which also offer solutions to issues with color, processability, mechanical properties and chemical migration in PCR materials.

Read MoreRead Next

Blow Molding News at K 2013

All-electric machines of all types were the stars of the show, but there were a number of other noteworthy developments.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More