Composites Getting Faster and More Automated

Molds that can change configuration, automated tape laying and winding, robotic sprayup, and faster prepreg molding processes highlighted the focus on productivity at the international composites show in Paris. RTM innovations round out this news report.

News at the big JEC composites show in Paris in April was all about speed and automation. New technologies include faster tool building, faster fiber and tape winding (thermoplastic and thermoset), faster RTM, faster automated prepreg molding, and fully automated sprayup of large parts like wind-energy blades.

Morphing molds

Two companies displayed unusual tooling with the flexibility to change dimensions. Surface Generation Ltd. in the U.K. (represented here by Jim D. Gray & Assoc.), showed its patented Reconfigurable Pin Tooling, which is said to cut mold-building time in half for prototyping and short runs of parts with complex compound curves.

It uses a bed of square pins, which are automatically raised and lowered by computer software to different heights to form a rough contour of the desired shape. The pins are then CNC machined into a finished mold much more rapidly than a solid block of material because the CNC cutter has so much less material to remove. As pins are gradually consumed, they are coded with matrix or RFID tags to indicate how much is left, so that the software can optimize reusing them for another pattern or mold. When design changes are required, pins in local areas of a tool can be raised or lowered for faster, less expensive reworking.

For high-pressure tools (up to 30,000 psi), pins can be made from aluminum, carbon fiber, graphite or steel. For low-pressure molds, aluminum pins are used to make a reverse shape that corresponds to the part. Then polyurethane, epoxy, or foundry sand is cast over the pins to make a short-run mold, which is finished by CNC machining.

Surface Generation sells software to analyze mold shapes, plus a bed of pins, CNC automation to adjust the pin heights, and software to design and store mold shapes using the raised pins. The biggest pin the company has built so far is 20 in. square and weighs 450 lb. The smallest is 1 in. square with tolerance of 0.0001 in. The biggest bed of pins built to date is 6 x 3 ft, incorporating 225 6-in. pins. The smallest is 1 ft square with 61 2-in. pins. The company has also developed a system that mixes pin sizes.

A second flexible mold system that can change part dimensions is for RTM. Invented by FiberCore Europe BV in the Netherlands, it uses a single variable tool to mold free-span composite bridges measuring from 1 to 30 meters in length or width. This avoids the high cost of one-off tooling and makes plastic composite bridges cost-competitive with concrete, FiberCore says.

On display at JEC was the largest free-span composite bridge ever built (24.5 m long x 5 m wide), which means it isn’t suspended from cables or supported by an arch. The bridge was molded in one piece out of vinyl ester from DSM and carbon fiber (Panex 35 from Zoltek Co.) over FiberCore’s own glass-reinforced, honeycomb-like core material. It was installed after the show in Holland for pedestrian, bicycle, and emergency vehicle traffic. It carries 82.5 tons and weighs 12.5 tons, vs. a weight of 176 tons for an equivalent concrete bridge. FiberCore molds only the span, fitted with hooks to lift it in place. Architects design end supports and hand rails to client specifications.

Faster taping & winding

Two companies showed unusual processes for dramatically faster fiber winding and tape laying. The Institut fur Verbundwerkstoffe GmbH (IVW), a composite R&D group in Kaiserslautern, Germany, won a JEC innovation award for a wet-winding head with a ring of eight movable arms. It’s reportedly three times faster than current methods using winding heads with up to four arms. The eight-arm ring is, however, limited to wrapping an axially symmetrical shape, like pressure tanks for hydrogen-fueled hybrid cars. It also uses new impregnation technology, which reduces leakage and uses less resin. The IVW has built two prototypes, one for its lab and one for Toyota.

FiberForge Inc. in the U.S. is supplying the first commercial system of its high-output tape-laying machinery for carbon-fiber-reinforced thermoplastics. FiberForge’s first licensee, Cutting Dynamics in Avon, Ohio, will use the ALS (automated layup system) equipment to make seat frames for commercial aircraft, replacing aluminum. FiberForge has licensed a second system as well.

The patented technology lightly tacks carbon-fiber/thermoplastic tape at precise locations on a flat 2D thermoplastic blank (U.S. Pat. 6607626). This is much faster than robotically laying wet tape onto a 3D part blank. The flat, near-net “tailored blank” is then thermoformed into a 3D shape (U.S. Pat. 6939423). Directional fiber placement optimizes strength and stiffness.

The tape head is fixed over a moving table with three axes of movement: x and y flatbed tractors and a rotating top. The fully automated system produces a part in less than 4 min. It’s currently sized for blanks up to 1 meter square, but Fiberforge says systems could be built to form parts up to 2 or 3 m square. Core components of Fiberforge’s system are built by Accudyne Systems.

Ingersoll Machine Tools introduced a system to heat thermoset or thermoplastic carbon-fiber prepregs with infrared lamps to make them tacky before placing them on a mold. IR heat is more even and controllable than the conventional use of hot gas jets.

News in RTM molding

Shoreteam Co. in France, an R&D group for RTM technology, showed a new trimless Inside Channel Process for RTM, which fills parts using a single entry port for resin and a single vacuum port. Resin goes into a channel inside the core layer of the fiber sandwich, so the part needs no trimming after molding.

LOF tech Sarl in France has developed a patented one-shot RTM system to make a seamless hollow part using a bladder. LOF tech molds a one-piece kayak, which went into production last February. Resoltech Sarl in France collaborated by developing a very low-viscosity epoxy for the process. The technology, which LOF tech offers for license, is also being used to produce long, thin, hollow parts like sailboat spars.

Roctool Sas in France (U.S. office in Atlanta), introduced a high-speed RTM process using its Cage System of electromagnetic induction-heated molds to reduce cycle time by as much as 50%. Since only the surface of the tool is heated, it heats and cools much more rapidly than conventional molds. Roctool offers licenses on this new high-speed RTM Process

Faster prepreg molding

Car hoods represent one of the last big opportunities on auto bodies to replace metal with plastic, so they’re getting close attention. Gurit (formerly SP Systems) in the U.K., a supplier of epoxy-based prepregs, is becoming a Tier One automotive parts supplier. Gurit (North American office in Canada) is building a new plant in the U.K. to mold lightweight hoods and other auto body panels for special-edition cars with short runs of around 3000 parts.

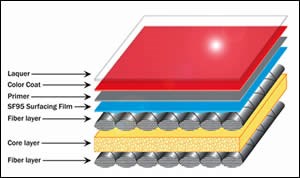

Gurit’s process doesn’t need an autoclave to remove air bubbles during molding. Its Sprint CBS (car body sheet) multi-layer film/fiber laminates are molded in a heated tool, followed by a semi-closed tool process with a vacuum bag. The process, developed under a U.K. government research grant, reportedly makes lower-cost parts than traditional carbon-fiber prepregs.

The hood is made of a single layer of Sprint CBS prepreg, which has dry fibers on the surfaces, epoxy resin films underneath, and a syntactic-foam core in the center. Gurit cuts the prepreg material automatically, assembles it in kits, cures and consolidates the kitted material in a vacuum press with relatively low-cost tooling, which removes the air. Then the panel is molded with a light SF95 surfacing film to pull air away from the surface and suppress fiber read-through. Cycle time is 60 min at 248 F or 30 min at 266 F, compared with several hours in an autoclave. Hoods demold with a ready-to-paint surface, Gurit says, and are then primed, painted and lacquered. The hoods go into production this summer.

Innomat GmbH and Dr. Mirtsch GmbH in Germany have developed a continuous in-line prepreg “structuring” and curing process that imprints a continuous pattern of hexagonal indentations onto sheet without the wall thinning seen with conventional embossing. The regular indented honeycomb pattern increases sheet stiffness and allows thinner sheet to be used. Such 3D “structuring” has been used for a decade in metal sheeting but is new to thermoset plastics.

The continuous process takes thermoset prepreg, “structures” it, and cures it in-line with either light or heat. Innomat developed the prepreg formulation, and Dr. Mirtsch built the heating and structuring machinery, which uses elements on rolling wheels to indent the pattern.

Scholz Maschinenbau in Germany has built what is believed to be the first microwave composite autoclave for R&D at the German Aerospace Agency (DLR) in Braunschweig, Germany. It reportedly can cure carbon-fiber prepregs faster and more efficiently than convection heating the whole mass of the autoclave with hot air. The R&D autoclave is equipped with microwave heating at one end and conventional electric heating at the other, allowing tests that compare or combine the two.

Microwave ovens have been developed before to heat prepregs more efficiently, but without autoclave pressure. Pressure improves the evenness of prepreg heating, Scholz says. The microwave autoclave is 1.6 m diam. x 4 m long and has 96 microwave field emitters.

Automating wet sprayup

Two exhibitors showed new robotics to automate sprayup systems for more repeatable processing of very large composite parts. Matrasur Composites in France showed new integration of robots into what is reportedly the first 100%-automated sprayup process. Matrasur offers three types of robots: teachable Robomat, conventional Robostrat, and fiber-cutting Usimat. Operators don’t need special qualifications to program Robomat, a lightweight, carbon-fiber, six-axis robot, which is installed on a bridge that adds six additional axes.

The robot is programmed via lead-through teaching. The operator holds the robot’s spray gun and leads it through a sprayup routine with gel coat, resin, or resin and glass. Afterward, the operator pushes a button to record it for the robot. The robot can then reproduce the same gesture alone.

ABB’s robotics div. in the U.S. has also devised (but not yet built) a robot capable of spraying gel coat onto wind-energy blades of any length. ABB uses an unusually flexible, wall-mounted, six-axis robot, model IRB 5500, which ABB launched last year. It has a reach comparable to a standard robot on a 6-meter rail. When the already long-armed robot is mounted on rails, it can spray gel coat on wind blades of any length, ABB says.

Read Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More