Compressed Air: Optimize Treatment and Distribution to Save Energy

In previous articles, we discussed the enormous waste of energy and money that occurs every day in many plants due to inefficient use and generation of compressed air.

In previous articles, we discussed the enormous waste of energy and money that occurs every day in many plants due to inefficient use and generation of compressed air (Energy Miser Oct. ’10, Nov. ’10, July ’11, Aug. ’11). Optimizing the supply is not only about efficient generation, it is also about making sure the compressed air gets to the application in the correct state (dry and oil-free) and in the most effective manner.

TREATMENT: GETTING THE RIGHT LEVEL

Compressed air must be treated to remove oil and water vapors and other contaminants, and the quality of the air can have a significant effect on the reliability and maintenance cost of the system. Treatment is an expensive operation, but even companies who are good at managing compressed air can fail in this area.

Oil/water separators, dryers, and filters all either use energy directly or create flow restrictions that increase the energy needed to supply the compressed air. Most of these devices are forgotten after installation, and poor or inadequate maintenance leads to excessive energy use.

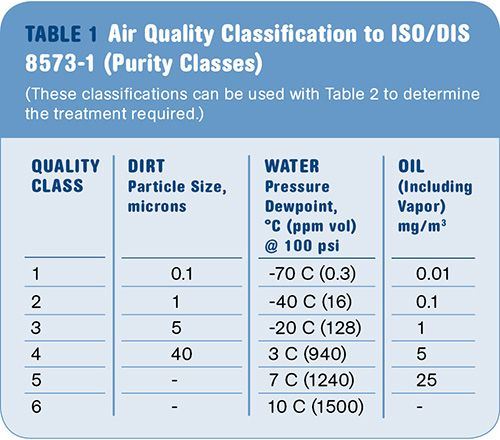

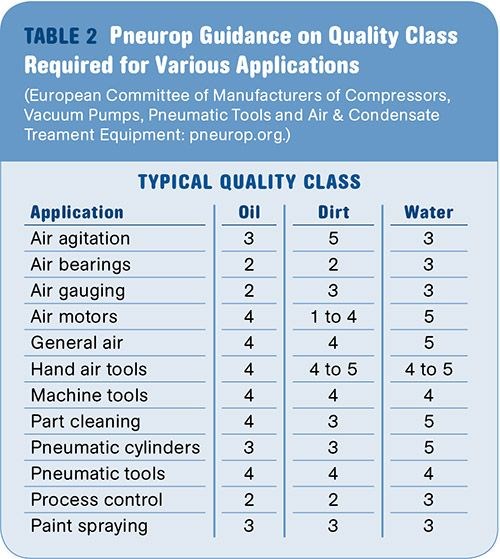

Treatment costs depend on the air quality specified, but most companies have no idea of the specification to which they are producing compressed air. Guidance on the quality classifications for compressed air is given in Table 1 and guidance on typical quality requirements for applications is given in Table 2. Plants should find out what quality class their system is producing and what quality class is actually needed for their applications. For most applications in plastics processing, Class 4 is sufficient and treating all the compressed air to a higher quality (Class 3 or above) is both unnecessary and expensive.

•Use the minimum quality of air needed. The higher the quality, the higher the energy cost.

•If a specific application needs high-quality air, then consider reducing the treatment quality of the bulk air and upgrading the quality as necessary at the point of use.

COMPRESSED-AIR DRYING

Dryers are used to remove water vapor from the compressed air and will use significant amounts of energy. This is particularly true if the requirements are set too high for the application.

•Make sure the temperature of the air inlet to the dryer does not exceed 35 C (95 F) and that dryer-room temperature is within 5° C (9 °F) of the outside ambient temperature.

•Check that the condensate collection system is not constantly bleeding air.

AIR FIL TRA TION

Filters cause pressure drops and to save energy it is recommended that only the minimum filtration requirement be met. Filters should be adequately sized for the duty and should be regularly checked for cleanliness.

•Treat the bulk of air to the minimum quality necessary: 40-micron filters are usually sufficient.

•Test filters regularly. The cost of the energy to overcome a pressure drop >6 psi is usually greater than the cost of a filter. Blocked filters can cost real money.

•Replace manual condensate traps with electronically controlled traps.

DISTRIBUTION: GETTING IT THERE

Distribution costs are hidden, and improving the distribution system can produce large reductions in the cost of supplying compressed air. In many cases the distribution system is a bottleneck and plants will increase the pressure in order to get the needed amount of air to the application. The need is for “cfm” (cu ft/min) but they substitute “psi” to make it work.

DON’t NEGLECT RECEIVERS

Receivers are the big metal tank at the end of the generation area. They perform several vital services: They provide storage to allow compressors to go off-load when not needed. They

allow the system to cope with high transient demands. They smooth out generation pulsations, and they act as a secondary cooler for the compressed air. Despite these vital functions they are most often ignored and rarely considered.

•An inadequately sized receiver will result in excessive cycling of the compressor.

•Receivers must (legally, in most places) be regularly inspected and fitted with a working safety valve.

•Receivers should have a working pressure gauge. This is to measure the pressure actually being supplied to the system. You need to know what it is.

•If the system is large, it’s worth considering putting smaller local receivers at some distance from the main receiver.

SYSTEM DESIGN & MAINTENANCE

Compressed air is a fluid and will suffer from a pressure drop over the length of the distribution system: The longer the pipeline, the greater the pressure loss. Systems also grow with time (but rarely shrink), and in many cases the total extent and layout of the current distribution system is actually unknown to plant management.

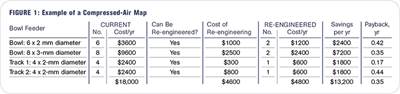

•Map the system to record the location, size, and condition of the distribution piping.

•Remove or totally isolate any redundant spurs or branches.

•Design systems to allow zone isolation and shutdown.

•It is always cheaper to use good-quality distribution piping in the long term. Pressure losses will be less, corrosion will be reduced, and the overall lifetime cost will be minimized.

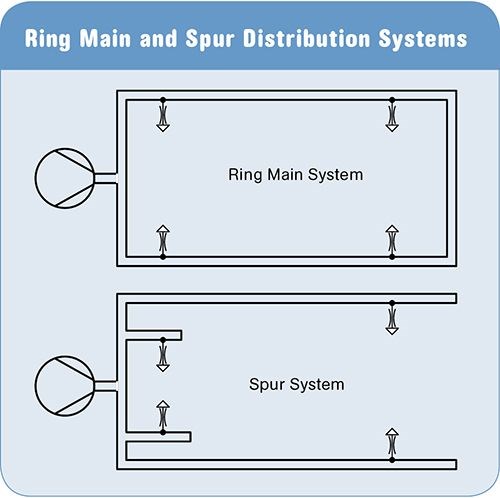

•Ring main systems (see diagram) allow air to converge from two directions. That reduces pressure drops and makes changes to the system easier.

•When fitting or refurbishing a system it is best to use the largest possible pipe diameters (4 or 6 in. is best). This reduces pressure drops and distribution losses and can act as a secondary receiver to smooth demand fluctuations.

HEAT RECOVERY

Most of the energy put into a compressor is rejected as heat and in many cases it is possible to recover this rejected heat for use in other applications. Heat-recovery systems can use the hot air

or warm water from the compressor for space heating or hot-water supplies.

•Space heating: Warm outlet air from the compressor is often vented directly to the atmosphere via ducting or grills. If the compressor is near the production areas, this heat can be ducted to provide free heating. This ducting should be fitted with a thermostatically operated flapper bypass to divert the heat inside in winter and outside in summer to prevent production areas becoming too hot in summer.

•Hot water: Simple plate heat exchangers can provide hot water for the plant for staff washroom and other purposes. This water can be provided at general domestic hot-water temperatures (up to 60 C/140 F), but it requires storage and control systems to get the full benefits.

Read Next

Compressed Air Isn’t Free!

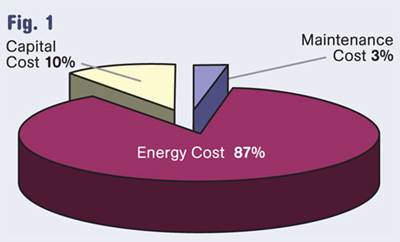

Compressed air is a convenient and often essential utility, but it is very expensive to produce, and most of the energy used to compress air is turned into heat and then lost to the system and environment.

Read MoreEnergy Miser: Plug Costly Compressed-Air Leaks

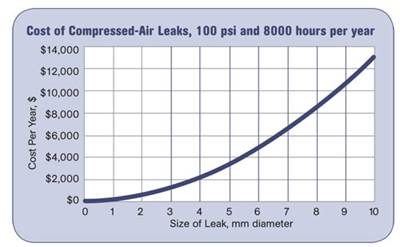

Last month we introduced the idea that compressed-air usage is one of the first places any manufacturer should look to reduce energy cost.

Read MoreEnergy Miser: Reducing Compressed-Air Usage

Many manufacturing sites operate on the assumption that compressed air is free. Usage is totally uncontrolled, and open air lines cost real money.

Read More