Energy Miser: Reducing Compressed-Air Usage

Many manufacturing sites operate on the assumption that compressed air is free. Usage is totally uncontrolled, and open air lines cost real money.

In a previous article (Nov. 2010), we discussed the first step to optimizing energy-intensive compressed-air usage—which is to plug wasteful leaks. The second step of a compressed-air optimization program is to reduce usage where possible. For many plants this is the most important and cost-effective step. Reducing usage minimizes the demand, reduces generation costs, and allows correct sizing of the system.

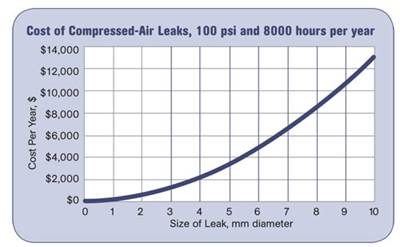

Many manufacturing sites, not only in plastics processing, operate on the assumption that compressed air is free. Usage is totally uncontrolled, and they fail to realize that open air lines cost real money: For example, a 3-mm open air line at 100 psi will cost you around $1300 per year—the same as a leak. In many cases, also, compressed air is used for applications where almost any other type of power would be cheaper.

THE COMPRESSED-AIR MAP

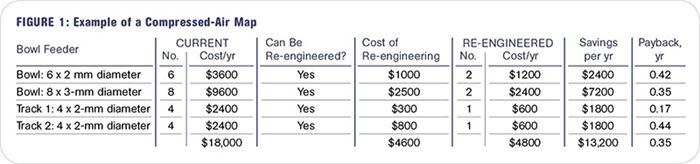

An important tool in reducing usage is a “compressed-air map” of the site. This is a survey of the complete usage of compressed air and an assessment of both the cost and the real need for using it. A compressed-air map will inevitably reveal many areas where the process can be easily changed to reduce compressed-air usage and costs.

Use of compressed air for actuators, cylinders, and slides often consumes a very low volume of air because these are “closed” applications where very little air is discharged to atmosphere—i.e., only the volume of the cylinder or actuator. The real energy hogs are when compressed air is used for “convenience” applications where a quick fix was needed in the past but has now become part of the operating environment. Examples found in real-world plants are an open 3-mm air line used to move plastic bottles across a conveyor (cost: $1300/yr per line) and two 3-mm open air lines used to pre-bend PS foam egg cartons (cost: $2600/yr). Open air lines are effectively “leaks.”

The compressed air map should include any and all open air lines used for the following, where compressed air costs more than simple alternatives:

•Cooling (of product, motors, or tooling);

•Moving (product or raw materials);

•Cleaning;

•Testing;

•Hand tools.

The compressed-air map can be used to quantify the cost of compressed air for each application, the possibilities for re-engineering the process, and the potential costs of the re-engineered process. It often comes as a surprise to quantify the true cost of using compressed air, and that simple calculation often drives reduced usage.

Applications in the compressed-air map should be categorized as either “optional” or “vital.” All optional uses should be closely examined for re-engineering to eliminate that use altogether. It is rarely difficult to justify the cost of re-engineering when the cost of the current compressed-air usage is calculated. (Note: Reducing the use of compressed air will also reduce noise in the plant as an added benefit.)

RE-ENGINEER THE PROCESS

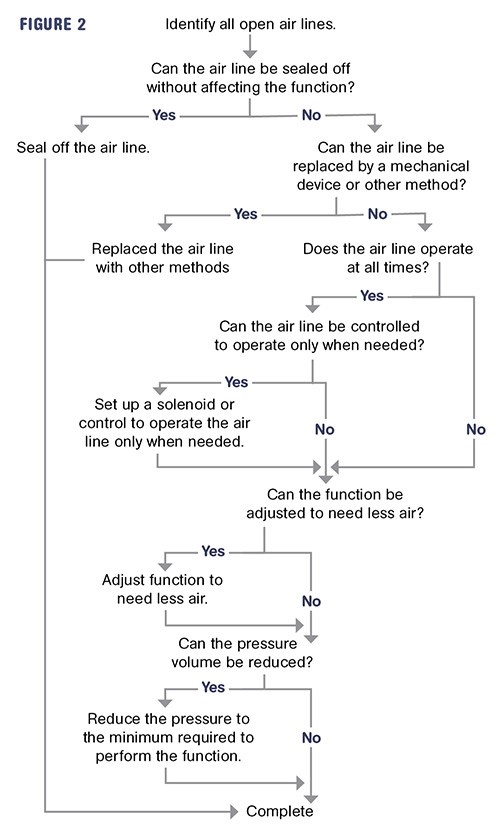

Re-engineering is often a simple matter of examining (in detail) the specific application and applying good engineering practice. A flow chart for reducing compressed air usage is shown in Fig. 2.

The size of the gains is often astronomical. We have worked with plants having substantial assembly operations (always an energy hog), and the standard target that we set for compressed-air usage is a 50% reduction within 12 months. In fact, with good techniques and dedicated engineers, this is generally achieved within nine months.

Related Content

The Effects of Time on Polymers

Last month we briefly discussed the influence of temperature on the mechanical properties of polymers and reviewed some of the structural considerations that govern these effects.

Read MoreKnow Your Options in Injection Machine Nozzles

Improvements in nozzle design in recent years overcome some of the limitations of previous filter, mixing, and shut-off nozzles.

Read MoreThe Effects of Stress on Polymers

Previously we have discussed the effects of temperature and time on the long-term behavior of polymers. Now let's take a look at stress.

Read MoreGot Streaks or Black Specs? Here’s How to Find and Fix Them

Determining the source of streaking or contamination in your molded parts is a critical step in perfecting your purging procedures ultimately saving you time and money.

Read MoreRead Next

Energy Miser: Plug Costly Compressed-Air Leaks

Last month we introduced the idea that compressed-air usage is one of the first places any manufacturer should look to reduce energy cost.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More