Conair Rolls Out ‘Uptime Guaranteed’ Initiative, Guaranteeing Its Equipment’s Performance

Conair plans to walk the walk when it comes to ensuring the performance of all its equipment via what it calls the deepest service team in the industry and new Industry 4.0 tools.

Long-running investments in the technology it designs and builds, as well as the people and infrastructure needed to support it, coupled with new Industry 4.0 tools, has put the auxiliary equipment supplier in a position where it feels it can stand unequivocally behind its equipment.

“What we think is natural is kind of a next step to this notion of ‘Uptime Guaranteed,’” explains Conair President Larry Doyle. “Where we make a promise to the customer assuring them that our equipment will rarely, if ever, be the reason or the cause of that unintentional production stoppage.

“The industry has seen the evolution over the course of many, many years of people touting 24-hour service or touting parts in stock or touting all sorts of things to help support the customer,” Doyle says. “Whether or not they can back it up is a totally different story. One of the things that we’ve done differently over the years is put in things like a performance guarantee, where we’re not just warrantying equipment but we’re guaranteeing the performance of the equipment.”

With Uptime Guaranteed, Doyle says Conair will be able to tell customers exactly how close to 100% uptime they can expect from their equipment, based on their process parameters and other factors. Using this data, the company can then guarantee the uptime percentage, whatever it may be. “If the equipment doesn't meet those benchmarks,” Doyle says, “we will take ownership of the problem. We will fix or replace the equipment and work with our customer to make sure those uptime objectives are achieved. This is what we mean when we talk about Uptime Guaranteed.”

Doyle noted that Conair has long invested in and strengthened its service presence. The company’s Instant Access Hotline makes spare parts or service just a call away, 24/7. In addition, Conair’s service techs work from an inventory of more than 50,000 line items—over 1.5 million parts total. The company says it ships nearly 90% of parts orders within one business day and usually within 6 hours. If on-site assistance is needed, Conair’s team of field service professionals has almost 40 techs.

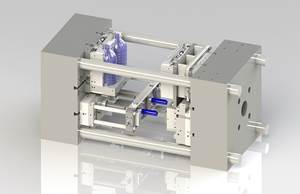

What’s also new at NPE2018, which ties directly into the existing Conair service proposition, is a new Cloud-based system called Conair SmartServices. Conair says SmartServices captures all of the data generated by controls on virtually all Conair equipment and many auxiliaries sold by other companies. A small module installed inside the equipment’s control panel wirelessly transmits all that process information to a database in the Cloud where it is stored and analyzed by proprietary algorithms developed by Conair. Processors can access the information from their equipment using a web-based platform that allows them to organize data by cell, plant, product line or more, and companies with more than one location can track all their equipment globally or zero in on an individual site.

Doyle says the SmartServices offering will not only be sold on new equipment but can retrofitted to select older equipment. “That will provide valuable insight into performance and monitoring of the equipment,” Doyle says. “It will be able to report back out diagnostics and help us with process optimization and understanding what types of data are really indicative as to how the machine is performing.”

At the company’s booth, Conair has different functioning systems with live services and interactive displays to let attendees see the gathered data, as well as SmartServices dashboards, both on equipment running at NPE but also equipment operating at customer sites and the company’s own lab.

Related Content

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreBASF Highlighting How They 'Make, Use and Recycle Future Solutions'

NPE2024: BASF is using its proprietary computer-aided engineering tool Ultrasim when designing for sustainability in a broad range of industries.

Read MoreAt NPE, Cypet to Show Latest Achievements in Large PET Containers

Maker of one-stage ISBM machines will show off new sizes and styles of handled and stackable PET containers, including novel interlocking products.

Read MoreInside the Florida Recycler Taking on NPE’s 100% Scrap Reuse Goal

Hundreds of tons of demonstration products will be created this week. Commercial Plastics Recycling is striving to recycle ALL of it.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More