Cooling Water: Minimize Demand by Reducing Heat Gains

Energy Miser: 13th in a Series

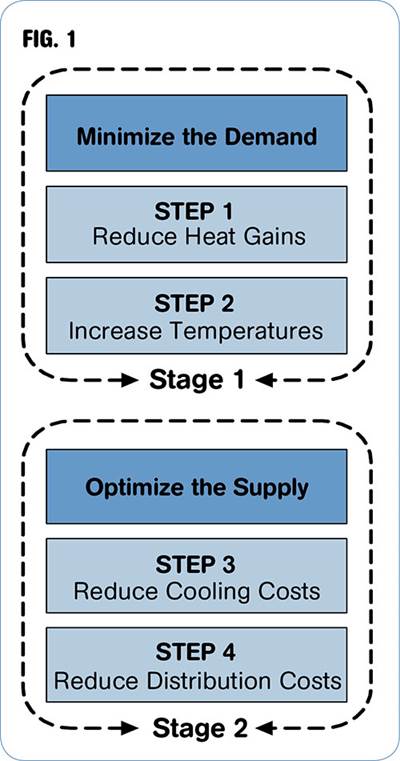

In March, we introduced the subject of energy savings through cooling-water management.

In March, we introduced the subject of energy savings through cooling-water management. The first stage in such a program is to minimize the demand, and the first step there is to reduce heat gains. Reducing heat gains will minimize the cooling load and can have a large impact on the running costs of any installation. Simply by identifying the heat loads and reducing these, it is possible to make major improvements to energy efficiency.

The important thing is the water temperature at the operating process and not the temperature as it leaves the chiller. There are two main areas for improvement:

1) Minimizing parasitic loads by insulating pipes, tanks and other components. This is particularly relevant where chilled-water pipes and pumps are in hot service areas, but heat gains can occur on any long pipe run where there is inadequate insulation.

2) Minimizing unwanted heat gains by providing chilled water only to areas where it is actually needed.

INSULATE CHILLED-WATER SUMPS

Chilling water to the correct temperature and then pumping it to a poorly insulated or uninsulated sump for storage or distribution is simply throwing away energy (and money). The water will warm up in a poorly insulated sump and the energy used to chill the water beforehand will be wasted. All chilled-water sumps should be well insulated to prevent parasitic heat gain. Simple retrofitted insulation can easily achieve this. This type of project will have a payback of around one year.

•Tip: Check the insulation levels of all your chilled-water sumps. This can be done by hand (feel for cold spots) or more accurately with a thermal camera.

•Tip: Apply or refurbish insulation as required to eliminate cold spots.

•Tip: Don’t forget to check that the tops of the sumps are in place, well fitting, and adequately insulated.

INSULATE CHILLED-WATER PIPING

Chilled-water piping is often left uninsulated in an attempt to reduce initial installation costs. This may save money in the short term but the chiller system will just have to work harder and use more energy to get the chilled water to the process at the right temperature. In the long term, leaving piping uninsulated will cost

more than if it was done right in the first place. If insulation is not fitted at the initial installation, then retrofitting will increase the cost but will still have a good payback. Insulation projects are cheap, easy to accomplish, and generally have a payback of 12 to 18 months, depending on the difficulty of installation.

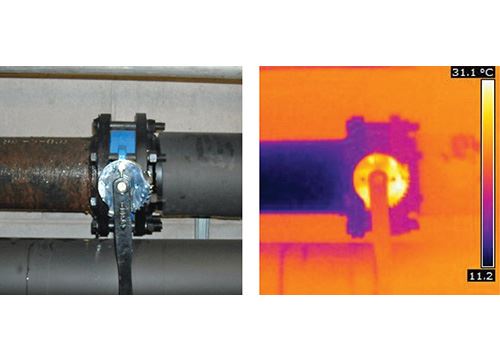

A thermographic camera survey will rapidly identify pipes that will suffer from parasitic heat gain and result in excessive chiller operation. Figure 1 shows a typical installation where some of the piping is insulated (lower and right areas) but the uninsulated areas (middle left area) are clearly seen as being colder than the

insulated areas. These areas will gain heat, increase the water temperature, and require the chiller to be set at a lower temperature to deliver the same temperature to the point of application.

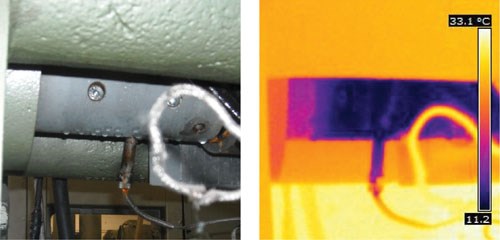

A thermographic survey is quick and provides excellent visual evidence, but it is relatively simple to find areas of parasitic heat gain by other means. If the piping feels cold to the touch or shows visible condensation, then parasitic heat gain will be taking place. Figure 2 shows a section of pipe with visible

condensation. The condensation on the pipe is an indicator of high parasitic heat gain and the plant is paying money to condense all of this water out of the air.

•Tip: Use the cooling- and chilled-water map to identify areas of uninsulated or poorly insulated chilled-water piping. These will be obvious in many cases because of the condensation that drips onto the floor.

•Tip: Parasitic heat gains will be highest on metal piping and that should be your first priority. Plastic piping (ABS or PVC) is less susceptible to parasitic heat gain, but it will still occur. This should be the second priority.

•Tip: Do not forget to look at the flexible plastic hoses from the drops to the machines. These will also suffer from parasitic heat gain. Maintenance will often strap the flexible hoses together with cable ties for neatness. This brings the cold-flow hose into intimate contact with the warmer return hose and increases parasitic heat gain. It looks tidy and neat but it is not energy efficient.

•Tip: Try not to run chilled-water piping in the roof void area. This will always be the hottest part of the plant (heat rises).

INSULATE COOLING-WATER PIPES, TOO

For most plastics processing plants in temperate areas, there is no real benefit in insulating (non-chilled) cooling-water piping. Cooling water is closer to ambient temperature than chilled water and insulation is not generally required, especially where plastic piping is used. The only exception is where cooling-water

pipes run through high-temperature areas.

Cooling-water insulation is not as profitable as chilled-water insulation and can have payback periods as long as four years.

STOP WASTE!

Pumping chilled water to idle machines is an outright waste that is seen at many plants. The machines are idle but the water continues to flow because the isolation valves are difficult or impossible to reach and the staff has not been told to isolate the machine.

Local isolation valves that are easily accessible and clearly signposted should be used to prevent the supply of cooling water to machines and tooling that are not being used. The best solution is to use automatic valves that are controlled by the control circuit of the machine.

•Tip: Include a run-on timer to remove any residual heat.

•Tip: Use the cooling-water map to identify areas that can be easily isolated.

Figure 3 shows a cooling circuit on an inoperative injection molding machine. Condensation is clearly visible and yet this cooling circuit had not been used for two years! For all of that time, the machine had cooling water circulating through it, using energy to operate the pumps and remove parasitic heat gain. What a waste.

MOLD-TEMPERATURE CONTROLLERS

If portable mold temperature controllers are used to either cool or heat specific tools, then it is good practice to look at the tubing that carries the cold or hot fluid. This can often be insulated easily to reduce the energy use by the mold-temperature controller.

NEXT: Minimize cooling water demand by raising process temperatures.

Related Content

Temperature Control Unit (TCU) Modulates Heat Output in Real Time

Delta T Systems’ Smart series water TCU features “Vari-Heat” technology for greater precision and efficiency.

Read MoreFree Cooling Chiller System Launches

Delta T Systems enters the free cooling space with a line that uses ambient air to cool the process fluid.

Read MoreTemperature Control Units on Display at PTXPO

technotrans says climate protection, energy efficiency and customization will be key discussion topics at PTXPO as it displays its protemp flow 6 ultrasonic eco and the teco cs 90t 9.1 TCUs.

Read MoreIs Your Water System Setup Helping or Hurting Your Molding Plant Productivity?

The plant water system is a critical component of an injection molding facility. A poorly designed or maintained water-cooling system can have a serious impact on production efficiency and cause many maintenance issues. Here’s what you need to know — and ask — to prevent those problems.

Read MoreRead Next

Introduction to Cooling Water Energy Management

A reliable and consistent source of cooling is essential in plastics processing.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More