Design-for-Manufacture Review on Micro-Molding Operations

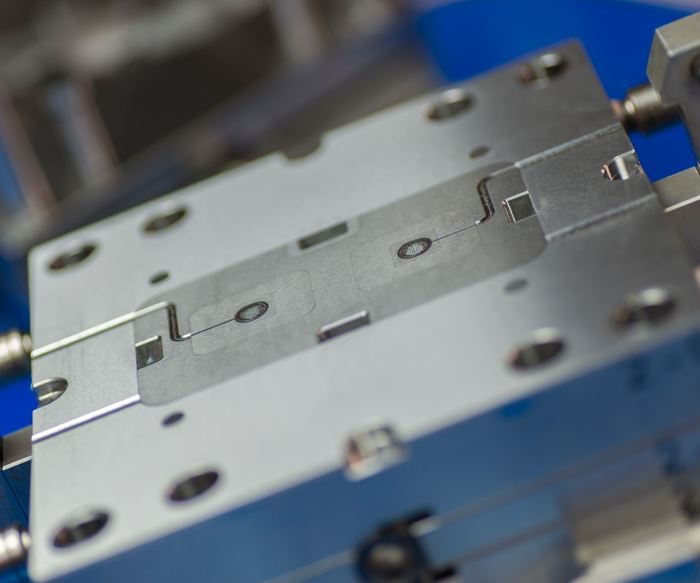

According to Mold Craft Inc., a design-for-manufacture (DFM) review ensures that its customers receive the highest quality molds that produce parts with close tolerances.

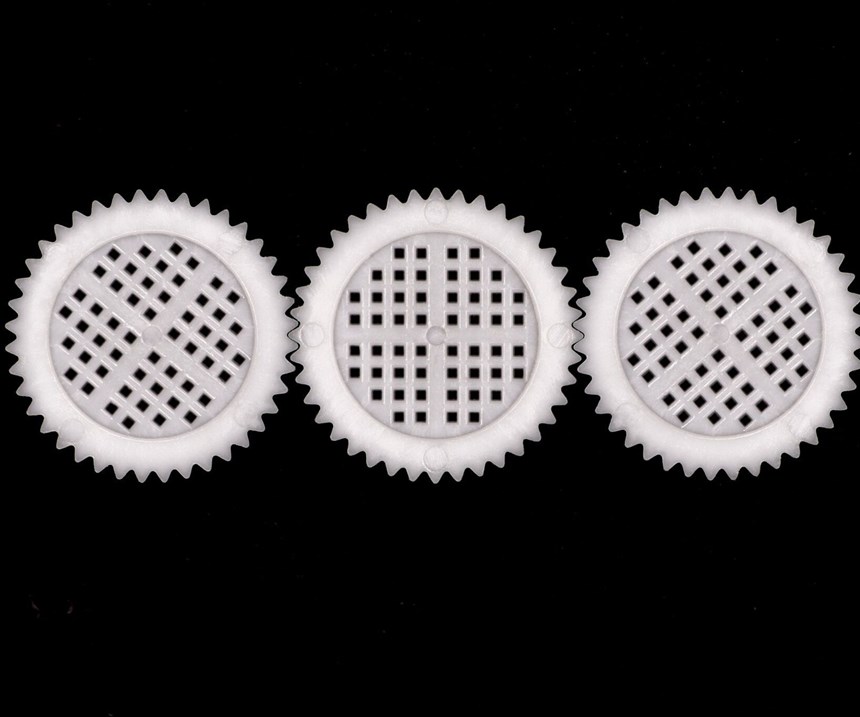

Mold Craft Inc. performs a design-for-manufacture (DFM) review on new micro-mold programs to optimize the experience of its customers. According to the company, the DFM review ensures that its customers receive the highest quality molds that produce parts with close tolerances. Mold Craft performs the DFM review on new micro-mold programs using a questionnaire. This helps establish moldability and project scope. The DFM questionnaire reveals topics of consideration, including part name, material, shrink, part weight, critical dimensions, gate and parting line location, acceptable ejection location and the automation plan for the final part removal. Other considerations include shot size, residence time, shot-to-barrel ratio, part orientation, features that require slide action, draft analysis, thickness and warp analysis, shut-off conditions, thin tool steel conditions, mating part discussion and the estimated annual usage. The review also includes available molding press tonnage, tie-bar spacing, barrel size, injection style and press manufacturer.

Visit Mold Craft in booth W4207 at NPE2018, where the Wittmann Battenfeld MicroPower 15t is displayed. Mold Craft also molds PEEK micro parts in Sodick’s booth (W782) using the LP20VRE vertical molding machine with two-stage plunger system.

Related Content

-

How to Achieve Simulation Success, Part 1: Model Accuracy and Mesh Decisions

Molding simulation software is a powerful tool, but what you get out of it depends very much on your initial inputs. Follow these tips to create the most successful simulation possible.

-

Design Your Tools for Moldability ... and Maintenance

In the initial design phase, when considering the structure and elements of the tool, are you designing them to be maintenance friendly? Canon Virginia has used this approach and preventive maintenance to make tool replacement a thing of the past. You can, too. Here’s how.

-

Back to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.