Designing a Thermoforming Plant For Efficiency and Productivity

On-Site: Formed Solutions, Inc.

Building a new plant in 2003 gave Lyle Schut a clean slate.

Building a new plant in 2003 gave Lyle Schut a clean slate. Formed Solutions, Inc. (FSI ), the company he had founded in 1998, had outgrown its facility in Holland, Mich. It was also limited by an inefficient layout in a former machine shop that had low ceilings, divided production into separate rooms, and required excessive handling to move product in and out of different operations.

Schut acquired six acres of land just a few miles away, more than enough to accommodate his growing custom heavy-gauge thermoforming business. But just as important, here was an opportunity to create from scratch the clean, modern manufacturing and working environment he envisioned.

START WITH A PLAN

Schut is not the sort to jump into a project like this haphazardly. His motto is, “Have a goal with a well thought-out plan.” He made a list of these goals for the new plant:

1) Modern and up to date;

2) Easy to organize and maintain;

3) Easy to keep clean;

4) Productive layout with efficient product flow;

5) Organized work cells with flexibility;

6) Safe and comfortable workplace;

7) Ability to expand for future growth

8) Affordable budget.

His next step was to list the basic requirements for the new plant and draw up a preliminary layout. Those basic requirements were as follows:

•Square footage required: 25,000.

•Power required: 2000 amps.

•Compressed air: 50 hp compressor, 2-in. loop, and 1-in. drops to the machines.

•Vacuum: two 15-hp pumps, 2-in. loop, and 1-in. drops.

•Water: 1-in. delivery.

•Office requirements: 6 office staff.

In addition, he resolved to research three possible sites, obtain budgetary quotations from three contractors, pursue financial planning with his current bank; and explore possible tax abatements with local agencies.

In the end, his “affordable budget” (goal #8) comprised $240,000 for real estate and $1 million for building construction. During the planning stages, manufacturing floorspace for the new facility was expanded by 12,500 ft2. This allowed room for a new 4 x 6 ft rotary former in addition to the existing pair, plus replacing a smaller (2 x 3 ft) one of the three single-station formers with a larger size (4 x 6 ft), and adding two more 5-axis CNC trimmers to the existing pair.

Schut says the project took six months from breaking ground until move-in. Production was maintained during the transition by moving the machines singly or in small groups and getting them up and running in the new plant while other machines were still running back at the old facility. A forming press can be disassembled, moved, reassembled, and back in production within a couple of weeks, Schut says. But a CNC trimmer can be shut down, moved, and started up again in the same week. All the machines were moved to the new plant in a space of three weeks.

DESIGN FOR PRODUCT FLOW

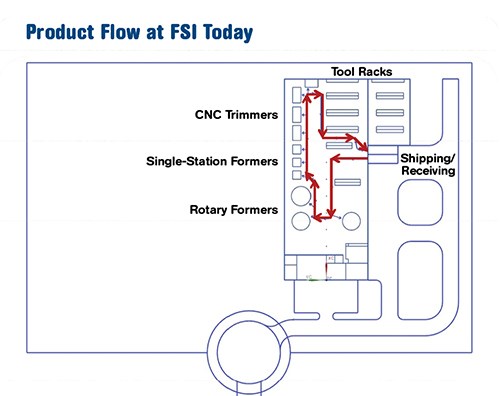

A key goal for the new plant was a more efficient production layout that would reduce or eliminate redundant materials and parts handling. The layout on p. 39 shows the “racetrack” product flow from receiving to forming, trimming, and back to shipping.

Machines are organized into work cells with plenty of space to move around. Sheet dryers are located close to the forming machines, as are the bandsaws (one near each former). Flexibility is provided by large work tables on wheels.

CLEAN, SPACIOUS, WELL LIT

The new plant’s interior is painted white for a clean look. Improved lighting enhances visibility. Machines are arranged spaciously so that all the operators are in view of each other and they can lend each other a hand when necessary. The supervisor and single forklift material handler also can see all the machines easily.

For ease of cleaning, the machines are placed well away from the walls and are mounted up off the floor on risers—no pits are needed.

While Schut decided t hat a ir conditioning the whole plant would be too expensive, employee comfort is provided by four 60-in.diam. ventilation exhaust fans that take the heat and dust out of the building and turn the air over completely every 5 min.

ROOM FOR GROWTH

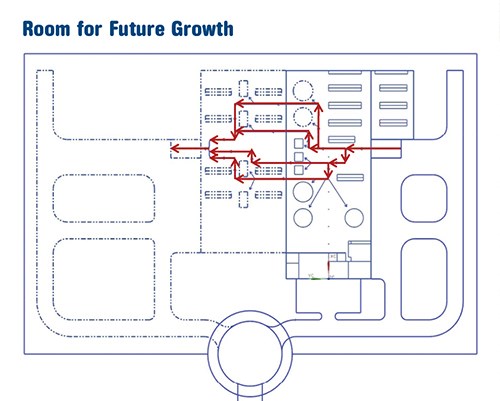

In late 2010, FSI added 6500 ft2 (at upper right of the floorplan) for tooling storage. “Enough storage space is always a problem,” Schut observes. Additional tool storage is provided in a plan for future expansion of an additional 37,500 ft2. This would allow for another plant reconfiguration that would segregate the forming and CNC trimming areas and replace the current racetrack design with a linear flow-through production plan in which materials and products move from receiving docks on the East side of the building through forming and then trimming, and then out through shipping docks on the West side.

Related Content

Cobot Creates 'Cell Manufacturing Dream' for Thermoformer

Kal Plastics deploys Universal Robot trimming cobot for a fraction of the cost and lead time of a CNC machine, cuts trimming time nearly in half and reduces late shipments to under 1% — all while improving employee safety and growth opportunities.

Read MoreIngenuity Is Part of This Former’s Name, and in Its DNA

Plastic Ingenuity started in a garage in 1972 and through a commitment to developing best-in-class products stands today as one of the largest custom thermoformers in the world.

Read MoreThermoformer Maximizes Productivity with 3D Printing

Productive Plastics has created an extensive collection of 3D printed manufacturing aids that sharply reduce lead times.

Read MoreAutomation in Thermoforming on the Rise

Equipment suppliers’ latest innovations exemplify this trend driven by factors such as labor shortages, higher-speed thermoformers and tighter quality control.

Read MoreRead Next

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More