Digital Twin Creates New, Virtual Paths for Robots with Real-World Cycle-Time Impacts

Realtime Robotics seeks to get more robots involved in manufacturing by addressing the biggest current barrier: programming costs.

Realtime Robotics, Boston, Massachusetts, grew out of two professors trying to answer one question: Why aren’t robots more prevalent? In a manufacturing market where labor remains scarce, why hasn’t the adoption of automation accelerated?

“It turns out that the answer is the high programming cost,” explains Alejandro Suarez, Realtime director of marketing. When the company broke down the life cycle cost of a robot, it determined that roughly 75% of that cost came in programming, with the rest being actual hardware, including the robot itself and end-of-arm-tooling (EOAT), as well as indirect costs like power and training.

Those professors — George Konidaris, who teaches computer science at Brown University, and Daniel Sorin, who’s a professor in electrical and computer engineering at Duke University — continued their discussion and would go on to found a new company, Realtime Robotics. The company is based on their shared interest in greater automation adoption. To do so, it would deploy technology Sorin has developed that is capable of reducing overall programming time by rapidly assessing the various paths a robot can take.

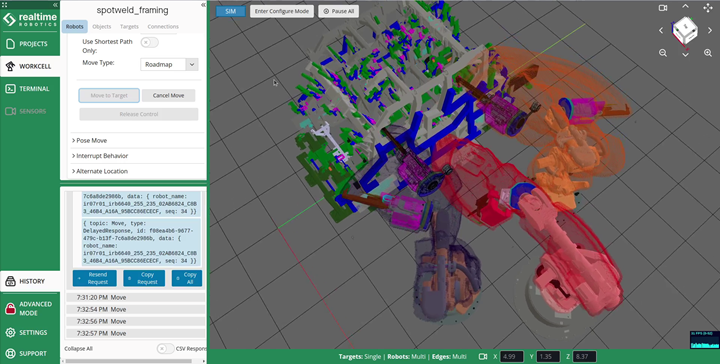

Today, Realtime bills itself as a leader in providing manufacturers with collision-free motion planning and robot control. Over the past year, Realtime says it’s taken that further and its new offering determines that collision-free path, optimizing automation that’s already in the field or currently being designed. “We’re taking our automated path planning, where you’re figuring out what’s the best path for a robot to take — what are the collision-free paths,” Suarez says, “and then we optimize that so we’re truly able to find the best path that’s collision free, reducing the cycle time even for multiple robots.”

At this stage, Suarez says the company essentially has two flavors of optimization. One is optimizing existing paths for a process that’s very defined and limited in where it can travel. The second involves the customer knowing the starting point and destination — point A to point B — but giving users the freedom to say, “Get me there as quickly as possible.”

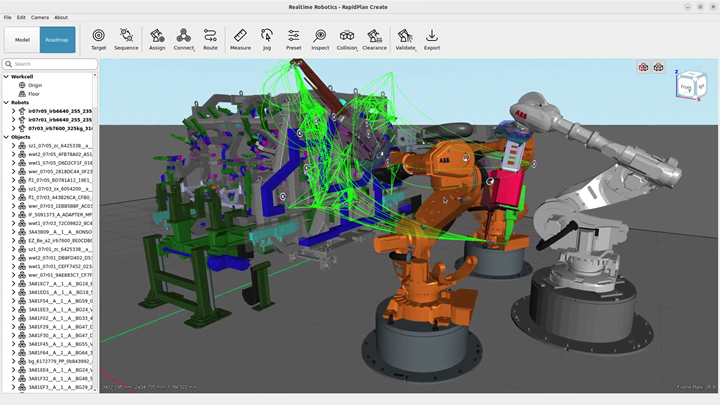

Realtime Robotics creates a digital twin of a cell to quickly compute the best possible paths and sequences for automation. Source: Realtime Robotics

Automated Automotive Assembly

As Volkswagen sought to revitalize its iconic minivan with the new electric-powered ID. Buzz, it turned to Realtime and its optimization-as-a-service product to determine the motion paths for its assembly and welding robots as it set up a new production line. Realtime did so, using its proprietary technology to evaluate hundreds of thousands of possible paths, sequences and sequence allocations for the robots.

“What if you assign five weld spots to one robot and six to the other, or six to the first and five to the other?” Suarez says, “Based on where they are positioned, it can analyze and figure out the paths.” All these calculations are happening on a scale and at a speed that human minds do not work at.

“We’re taking our automated path planning, where you’re figuring out what’s the best path for a robot to take — what are the collision-free paths.”

“It’s really, really difficult for a human to think about all these different combinations and permutations for a single robot,” Suarez says. “Now, imagine you have six robots working in a shared space. This is very exciting because we finally were able to get computers to do the hard work. We’ve been able to create this and to go through and find the absolute best solution.”

Optimizing Existing Lines

The traditional optimization of an existing or “brownfield” site requires the shop and its systems integrator to identify a bottle neck and posit possible solutions, requiring a shutdown to test out those theoretical answers.

“It’s really a trial-and-error process and typically for these projects, it’s the robotics expert that has 30 years of experience and all the scars from doing this that has a starting point for optimizing,” Suarez says. “They go in over a weekend and try to improve the paths, and maybe they get a little bit of improvement, but not to the point where you need. So, it’s still a bottleneck — less of a bottleneck — but still a bottleneck.”

With Realtime’s robotics optimization, Suarez says the process is faster and more thorough, taking days or weeks instead of months. The company’s process starts by receiving existing CAD models and creating a digital twin of the existing robot program, which it loads into its optimization software (it can also undertake a 3D scan of the line).

At this stage, Suarez says the company knows straightaway whether it can optimize the given automation process or not. “Right away we get a sense that, for example, we’ll be able to reduce the cycle time 1% to 5%. From there, the company then works with the end user to determine what are the parameters that can be changed and which ones are immutable. Next, Realtime works with the system integrator of choice for the client, telling the integrator how the robots need to be programmed and sequenced. “They take that and deploy it on the actual robots,” Suarez says. “They make changes to the PLC or any changes that are required for the entire system.”

Finally, Realtime validates the results in actual production, taking into account things like communication delays between the robot and the PCL, which can be difficult to simulate. “It might be that instead of saving 5 seconds, we’re able to save 4.8 seconds,” Suarez says. “We’re able to do this whole thing in a single weekend shutdown, because we already figured out the answer in simulation.”

Realtime says its platform is robot agnostic, having successfully optimized with Fanuc, ABB, Kuka, Yaskawa and more with most early clients among major automotive OEMs. More recently, it has branched into other sectors and tasks, including mixed-case palletizing.

Realtime Robotics can determine the possible paths, sequences for automation, weighing multiple factors like cycle time, energy efficiency and floor space utilization. Source: Realtime Robotics

Optimizing More than Cycle Time

Beyond cycle time and optimization for raw speed, Realtime is also fielding additional requests from its customers to enhance other aspects of their automation. In Europe, in particular, concern over energy costs has led customers to ask Realtime to find paths and processes that reduce cycle time as much as possible, while also creating a path that maximizes energy efficiency. “Energy costs are so top-of-mind that customers are saying, ‘Well, you optimized for cycle time, while keeping that cycle time, can you also reduce the energy consumption? Can you optimize for energy consumption?’” Suarez says.

“We figure out the paths for the robots, the interlocks, so you’re able to fit into your existing space quickly.”

In addition, customers are also keenly aware of available floor space. “Customers say, “So you achieved my cycle time. The robots are using less energy. Can you save me some valuable floor space?’” Suarez says. In Japan, he notes, right behind cycle time, its clients’ chief concern isn’t energy usage but real estate on the shop floor.

In plastics, where robots are often used to convert a manual process to an automated one, space is again a concern, with a new robot meant to occupy an area formally manned by a human. “What we’re able to do in a small space is figure out the optimal solution,” Suarez says. “We figure out the paths for the robots, the interlocks, so you’re able to fit into your existing space quickly.”

Realtime is working on another function that Suarez believes will be of interest to plastics processors: AutoHoming. Typically, in a cell where a robot might be performing pick-and-place or other machine-tending functions, if there is an error where production is stopped, maintenance techs must often use the teach pendant to jog the robot back home because it was stopped suddenly and might not be sure how to return.

As a stopgap measure, some processors will write up code giving the robot take-me-home routines from places it’s likely to stop, which is an imperfect solution. “It’s very dependent on where the robot is,” Suarez says. “You have to find a collision-free path back. If you’re not able to program it, it requires a human with eyes, a brain and hands to say, ‘OK, here’s the way to get out of that spot of the machine.’”

Often, this requires the current part to be scrapped, because a new part is required to reload the proper sequence. With AutoHoming, Realtime knows where the robot is at all times and what the surrounding environment is. With the press of a button on the HMI, an operator can send the robot back home automatically and, if required, it can go back to its last position before the alarm and continue the process.

The company believes this function can eliminate another reason why customers shy away from using multiple robots in one cell. “Not only do you have to return one robot,” Suarez says, “but you have to return two or three, but if they were able to continue production once you fix the problem that would directly improve the bottom line.”

Related Content

Automotive Awards Highlight ‘Firsts,’ Emerging Technologies

Annual SPE event recognizes sustainability as a major theme.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreImpacts of Auto’s Switch to Sustainability

Of all the trends you can see at NPE2024, this one is BIG. Not only is the auto industry transitioning to electrification but there are concerted efforts to modify the materials used, especially polymers, for interior applications.

Read MoreNew Facility Refreshes Post-Consumer PP by Washing Out Additives, Contaminants

PureCycle prepares to scale up its novel solvent recycling approach as new facility nears completion.

Read MoreRead Next

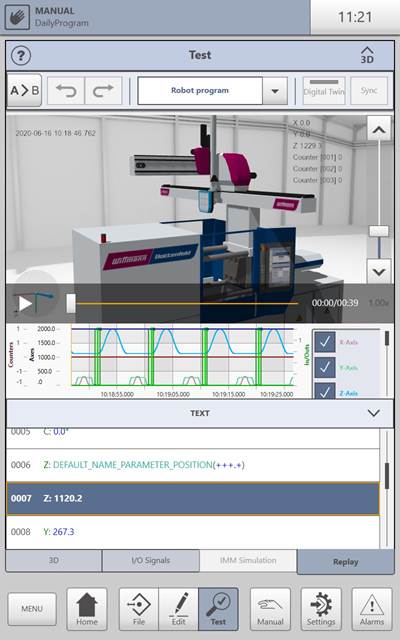

Automation: Digital Twin Allows Slow-Motion “Replays” of Robot Movements

Wittmann Battenfeld say all data are recorded in the R9 control’s video assistance system within 4 msec and can be traced back into the past for up to 100 seconds, letting molders replay incidents.

Read MoreChoosing the Right Projects to Automate

What are the strategies and upfront work that go into identifying production problems that could benefit from an automation solution?

Read MoreFakuma: Robot Makes Safe, Early Starts; Optimizes Path Planning

Engel is expanding its range of smart assistance systems at Fakuma 2021 adding the new iQ motion control to its viper series linear robots.

Read More