External Benchmarking of Injection Molding Energy Efficiency

In April, we discussed the use of the slope of the curve of process energy consumption versus production volume for internal benchmarking of energy efficiency.

In April, we discussed the use of the slope of the curve of process energy consumption versus production volume for internal benchmarking of energy efficiency. That curve is called the Performance Characteristic Line (PCL) and the term "internal benchmarking" refers to comparing present performance to a historical standard.

Despite the usefulness of the PCL for internal assessment, it does not by itself allow for the external benchmarking that is necessary to drive significant improvements in performance. External benchmarking is when you compare your plant's performance to that of your peers or competitors. If you are an injection molder, can you afford not to know how you compare with other molders?

Benchmarking is difficult for two reasons:

- Energy use in plastics processing varies with the type of process (as explained in previous columns) and each type of process thus requires a specific external benchmarking reference.

- Energy use in any process varies with the production rate but also incorporates the fixed or base loads associated with plant services and the high fixed loads found in most plastics processing machinery.

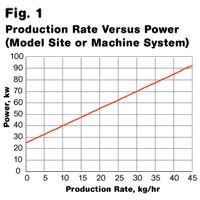

For all materials conversion processes (not just plastics processing), it is possible to set up a model system for either a plant or a machine, where the total electrical load (in kw) consists of a fixed base load (the services) plus a process load that is directly proportional to the production rate in lb or kg per hour. The total load for this type of system is shown in Fig. 1.

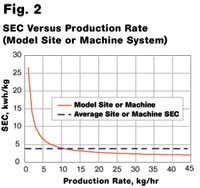

The conventional measure of process energy use is the Specific Energy Consumption (SEC), which is expressed as the number of kwh used to process 1 kg or lb of material (kwh/kg or kwh/lb). The SEC for this model system can be calculated for various production rates, as is shown in Fig. 2 along with a hypothetical average of SEC results collected from different plants or machines. It is obvious that the average plant or machine SEC is not representative of the model system and that any attempt to benchmark a plastics processing method must include the production rate to produce meaningful results.

This is because the fixed loads remain effectively constant whatever the production rate and must be amortized over the actual production volume. At low production rates, the actual process load is low and the fixed load of the plant and machine dominates the total energy use. Thus the effective SEC of the process will appear high. At high production volumes, the actual process load is high and the fixed loads decrease in importance, so the effective SEC of the process can appear much lower. This is a simple amortization of the fixed loads into the variable process load, and it has two important effects:

Comparing sites or machines is meaningless unless the base loads and the production rates are taken into account.

There is no conflict of interest between being "green" and being profitable. Running plants and machines harder increases the energy efficiency of the process because base loads are amortized over higher process loads at the higher production rates.

PROCESS OPERATING CURVE

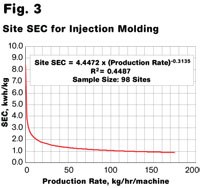

An operating curve for SEC (kwh/kg) versus production rate for injection molding has been generated from 98 injection molding plants throughout the world and the data has been fitted with a power-law "line of best fit" to produce the operating curve shown in Fig. 3.

This operating curve corrects the predicted SEC for variations in production rate, so it is now possible for an injection molding site to benchmark itself against other similar sites. This can be done by:

- Calculating your plant production rate (in kg/hr/machine).

- Finding the predicted plant SEC from Fig. 3 at your plant's production rate.

- Calculating your actual plant SEC from the total electricity use (kwh) ÷ total material processed (kg or lb).

- Comparing your actual plant SEC at that production rate with the SEC benchmark.

Individual sites can now carry out this simple process to determine their ranking relative to the average performance of the 98 sample sites around the world. Keep in mind that achieving the benchmark SEC is not a sign of good or best practice, only a sign of average practice.

MACHINE OPERATING CURVE

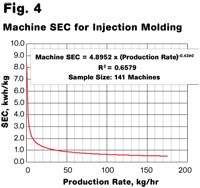

As with plants, it is also possible to benchmark individual machines, and the effect of the specific production rate is very similar. An operating curve for machine SEC versus production rate for injection molding has been generated from 141 hydraulic injection machines and tool combinations and the data has been fitted with a power-law line of best fit to produce the operating curve shown in Fig. 4.

This operating curve corrects the predicted SEC for variations in production rate and it is now possible for an injection molding plant to benchmark its individual machine and tool combinations against other typical machine/tool combinations. This can be done by:

- Calculating the average machine production rate in kg or lb per hr.

- Finding the predicted machine SEC from Fig. 4 at the specific production rate.

- Calculating the actual machine SEC from the total electricity use (kwh) ÷ total material processed (kg or lb).

- Comparing the actual machine SEC at that production rate with the machine SEC benchmark.

Plants can now benchmark their machine/tool energy performance relative to the performance of 141 sample machine/tool combinations—but achieving the benchmark SEC is, again, not a sign of good or best practice, only a sign of average practice.

About the Author

Dr Robin Kent is founder and managing director of Tangram Technology Ltd. in Hitchin, Herts., U.K. Tangram provides consulting engineering, training, and design services to plastics processors. Kent has been involved in injection molding and extrusion for 36 years and has worked as technical director for several major plastics processing companies in the U.K. and Europe. He can be reached at rkent@tangram.co.uk or visit www.tangram.co.uk. Articles in this series are adapted from his book, Energy Management in Plastics Processing (2008, 265 pages, www.pidbooks.com).

Related Content

Injection Molding: Focus on these Seven Areas to Set a Preventive Maintenance Schedule

Performing fundamental maintenance inspections frequently assures press longevity and process stability. Here’s a checklist to help you stay on top of seven key systems.

Read MoreKnow Your Options in Injection Machine Nozzles

Improvements in nozzle design in recent years overcome some of the limitations of previous filter, mixing, and shut-off nozzles.

Read MoreOptimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.

Read MoreGot Streaks or Black Specs? Here’s How to Find and Fix Them

Determining the source of streaking or contamination in your molded parts is a critical step in perfecting your purging procedures ultimately saving you time and money.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More