EXTRUSION: Another Technique for Controlling Melt Temperature

Flight widths are almost always designed at 10% of the screw diameter. But they can be optimized to reduce melt temperature and perhaps boost output.

On the vast majority of screws there is a general practice of using a flight width that is 10% of the screw diameter throughout the entire screw length. The screw flights preform a number of functions in the overall design. First, they create the helix that provides the conveying force for the polymer, and the helix angle generates the pressure necessary for conveying against the discharge pressure. In addition, the flights form a barrier between the channels, and they wipe the barrel, which aids in melting and reducing degradation on the barrel wall. Finally, they center the screw in the barrel and support the screw against unbalanced radial pressures, somewhat like a bearing surface.

With all these requirements, it’s obvious that their design is an important part of the overall screw design, so why are all of them 10% of the screw diameter?

The 10% practice seems to be more a matter of convenience for the designer and the manufacturer than an actual design consideration. It’s obvious that the flight width has an effect on the output, simply because it affects the channel width. It has also been clearly established that flight width affects melt temperature. In many cases the flight width can be narrower and still perform the functions of the helical flow path, generating pressure, wiping the barrel, and centering the screw in the barrel. The function of supporting the screw against unbalanced radial pressures, which occurs largely in the melting area, is an area where wider flights may be needed to act as a bearing surface. But even in that area, amorphous polymers seldom have the high melting forces that create the need for a wider flight.

However, bearing-type support is important for many crystalline polymers that can “wedge” in the melting or compression area and result in high flight wear. By using a wider flight in this area, and a narrower one in the remainder of the screw, the melt temperatures can be reduced, with the only compromise being a slight increase in leakage over the flights from channel to channel.

The tendency of a polymer to shear-thin largely determines how critical the flight width will be to the final melt temperature. Polymers that are more Newtonian do not shear-thin as much and as a result they have a greater heating effect when subjected to the very high shear rates occurring in the flight clearance.

In order to quantify this concept, I compared sample calculations of the heating in the metering section over the flight clearance for the same 4.5-in. screw using two different flight widths, processing polypropylene and nylon 66 at a fixed screw speed and open discharge. The analysis used the classical approach of Tadmor and displayed a melt-temperature increase in the metering section. Keep in mind that the polymer already had picked up a lot of temperature increase in the melting process, and this was added temperature after melting had been completed.

TEST 1. Lead 4.5 in., flight width 0.450 in., and radial flight clearance 0.005 in.

PP: 6% of total heating generated in the flight clearance.

Nylon 66: 19% of total heating generated in the flight clearance.

TEST 2. Lead 4.5 in., flight width 0.250 in., and radial flight clearance 0.005 in.

PP: 3% of total heating heat generated in flight clearance.

Nylon 66: 10% of total heating generated in the flight clearance.

The shear-thinning tendency of non-Newtonian behavior is described by the power law index. The higher the number, the more Newtonian and the less it shear-thins. The effect is substantial for nylon 66, which has a power law coefficient of 0.66, and relatively minor for PP, which has a power law coefficient of 0.38. See accompanying table for the power law coefficient for several types of polymers.

Based on the power law coefficient, polymers like polystyrene and PVC will shear-thin a lot and the effect of a narrower flight width in certain areas will not provide much improvement. For PP, LDPE, and HDPE there is an appreciable effect, and for nylon 66 and PC there is a very significant effect.

Here’s the takeaway: Optimizing flight width is one more aspect of design that can be used to reduce melt temperature with little negative effect. And since cooling often controls the output of many extrusion operations, it’s important to process at the lowest usable temperature. Use the power law coefficient as a guide to the effectiveness of this approach. This is not a radical concept. The approach of using the narrowest possible flights has been common for years in foam cooling screws and other melt-fed screws, but—for convenience—seldom in other extrusion applications.

Related Content

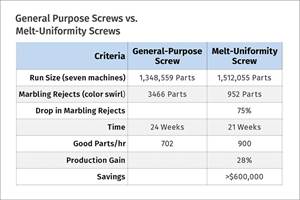

Improve Production Rates Via Screw Design — Barrier vs. General Purpose vs. Melt Uniformity

I’m looking for a few good molders to help trial a new screw design, and share data and results for a future article to prove the benefits of a melt uniformity screw.

Read MoreHow Screw Design Can Boost Output of Single-Screw Extruders

Optimizing screw design for a lower discharge temperature has been shown to significantly increase output rate.

Read MoreXaloy Invests in New R&D Center

Xaloy is investing in a new R&D Facility for plasticizing equipment in northeast Ohio with aid from JobsOhio R&D Center Grant.

Read MoreExtreme Coatings Names Jackson Director, North American Sales

Company also extends its global manufacturing footprint.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More

.jpg;width=70;height=70;mode=crop)