EXTRUSION: The Two Main Causes of Screw Wear

Wedging and misalignment are often confused with each other when inspecting a worn screw.

Two of the more catastrophic causes of flight wear on single screws are wedging and misalignment. They are often mistaken for one another when inspecting the screw. Here’s how to diagnose the problem correctly.

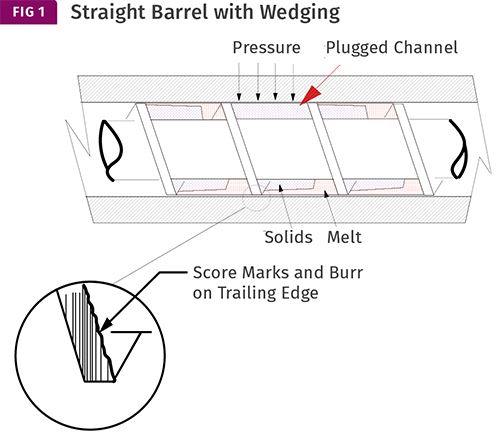

Wedging results from inadequate melting, which causes a short section of the screw channel to intermittently fill completely with unmelted polymer. This creates an unbalanced radial pressure that forces the screw aggressively against the barrel in the opposite direction. This occurs almost exclusively in the compression area of the screw, where the channel volume is being reduced. This has been covered in more detail in previous columns (Feb. ’12 and May ’13).

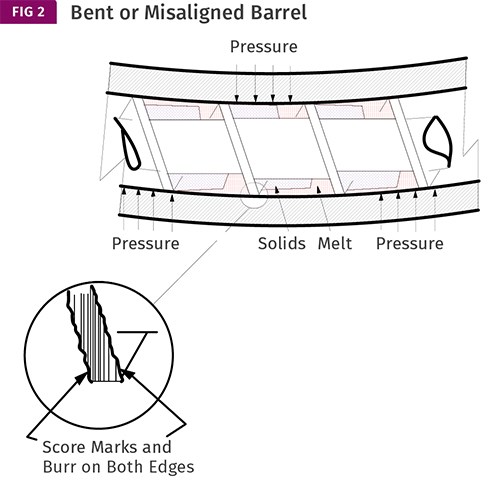

Wear resulting from bending or misalignment can occur anywhere on the screw and is caused by the screw bending while rotating to conform to a barrel bore. Remember barrels are typically many times stronger than the screw because of their higher moment of inertia, so the screw will bend to conform to it. I have also covered alignment in another column (Dec. ’09).

Wedging and misalignment create different forces and wear patterns on the screw. These should provide some clues as to what’s causing the wear because the screw will look different, depending on whether wedging or misalignment is the culprit. In both instances the screw will show galling.

Galling is “a form of wear caused by adhesion between sliding surfaces. When a material galls, some of it is pulled with the contacting surface, especially if there is a large amount of force compressing the surfaces together. Galling is caused by a combination of friction and adhesion between the surfaces, followed by slipping and tearing of crystal structure beneath the surface. This will generally leave some material stuck or even friction welded to the adjacent surface, whereas the galled material may appear gouged with balled-up or torn lumps of material stuck to its surface.” (Wikipedia.com).

When wedging or screw misalignment occurs, the high compressive forces on the flight squeeze out any polymer that normally lubricates the two surfaces. Wedging creates a localized sliding friction with a very high normal force. This force can persist for at least a partial revolution until the wedge breaks up by melting and/or pressure, depending on the conditions of the wedging. Because the flight has an angle to the circumferential direction of the sliding friction, it drags some of the flight material off the back or trailing side of the flight.

If, on inspection, you see crushed flights, a misaligned barrel is likely the reason. A screw that’s conformed to the bent barrel experiences a larger direct and opposing compressive force on its flights, depending on the degree of misalignment. That force tends to crush the flight as the screw is forced to conform to essentially a reduced bore caused by the misalignment. The crushing force—when coupled with the same high frictional force as in wedging—causes very rapid wear.

While wedging results in a “burr” on the trailing side of the flight (see Fig. 1), misalignment produces a burr on both the trailing and leading edges of the flight due to the crushing and frictional effects (Fig. 2). In either case, the flight material is being displaced by the flow of the metal due to the pressure and/or adhesion between the screw flight and barrel wall. The best choice of material for the screw flights is usually determined by a combination of its tendency to resist galling under high loads and its hardness.

Although both wedging and misalignment cause rapid wear, misalignment often is more catastrophic because of the combined effects of adhesive wear and crushing. In hundreds of screw inspections the tell-tale burrs have been helpful in determining the cause of the wear and the solution. It’s not unusual to have both types of wear but in different parts of the screw. As noted, wedging occurs almost exclusively in the compression section of the screw or in highly restrictive mixers that become plugged with unmelt. On the other hand, misalignment can occur anywhere along the screw.

ABOUT THE AUTHOR: JIM FRANKLAND

Jim Frankland is a mechanical engineer who has been involved in all types of extrusion processing for more than 40 years. He is now president of Frankland Plastics Consulting, LLC. Contact jim.frankland@comcast.net or (724)651-9196.

Related Content

Improving Twin-Screw Compounding of Reinforced Polyolefins

Compounders face a number of processing challenges when incorporating a high loading of low-bulk-density mineral filler into polyolefins. Here are some possible solutions.

Read MoreThe Effects of Stress on Polymers

Previously we have discussed the effects of temperature and time on the long-term behavior of polymers. Now let's take a look at stress.

Read MoreWhy Shoulder Bolts Are Too Important to Ignore (Part 1)

These humble but essential fasteners used in injection molds are known by various names and used for a number of purposes.

Read MoreHow to Select the Right Cooling Stack for Sheet

First, remember there is no universal cooling-roll stack. And be sure to take into account the specific heat of the polymer you are processing.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More

.jpg;width=70;height=70;mode=crop)