EXTRUSION: Why Barrier Screws & Rigid PVC Don’t Always Mix

RPVC’s somewhat unusual melting mechanism makes it unsuited to traditional barrier type designs.

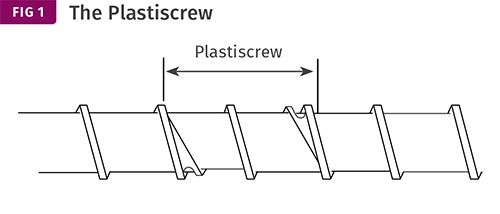

For years I had been relatively unsuccessful using barrier screw designs for rigid PVC. As a result, I more or less stopped designing them for this particular material...without knowing the basic reason they did not meet expectations. I was also always surprised by how well the 1960s design by NRM, known as the Plastiscrew, worked on rigid vinyl compared with many of the various barrier screw designs. Davis-Standard has since bought NRM and now holds the trademark on the Pastiscrew.

A Plastiscrew section (Fig. 1) is essentially a short barrier flight that crosses the main channel with an undercut O.D. that acts like a dam with no provision for separating or accumulating the melt, unlike a barrier screw.

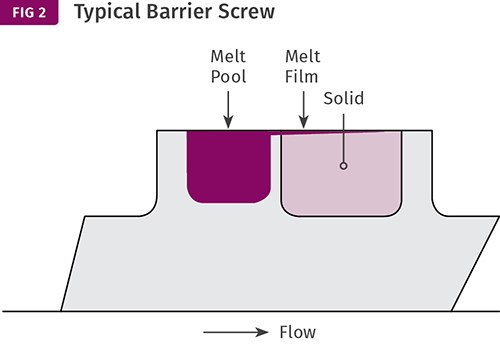

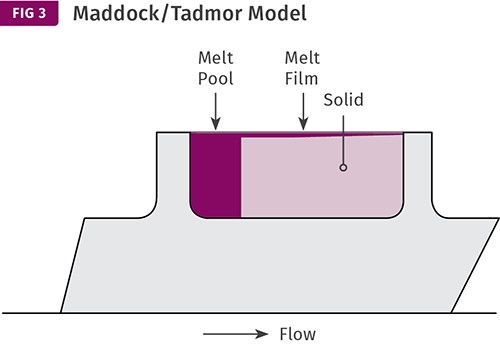

It became obvious that RPVC had a somewhat different melting mechanism that made it unsuitable for the principle of the typical barrier screw (Fig.2), which assumes the melt film forms in the solids channel and is allowed to pass backward over the undercut barrier flight and accumulate in the melt channel. Those designs utilize the well-known concept from the traditional Maddock/Tadmor melting model (Fig. 3).

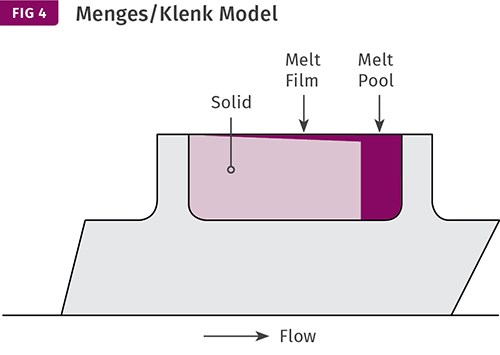

But while the Maddock/Tadmor melting model is the most widely known and used among screw designers, it is not the only model identified by researchers. A model called the Menges/Klenk has been shown be appropriate for RPVC. It works almost in reverse of the Maddock/Tadmor model, with the melt accumulating behind the flight rather than in front (Fig. 4). So instead of the melt film being formed over the solid bed and accumulating in front of the flight, it accumulates behind the flight.

As a result, RPVC would not perform well on a barrier design using the principles of the Maddock/Tadmor model. The melt pool is on the wrong side in the main channel, making passage to the melt channel difficult. This would be a very inefficient model, with melt eventually accumulating in both the melt channel and the front of the main channel as melting progressed. This could result in substantial thermal differences within the melt.

It also seems likely that this “counter-flow” would enhance breakup of the solid bed—whose integrity is an advantage of barrier designs—and further degrade the thermal uniformity of the extrudate. In fact, poor melt homogeneity has been my experience with Maddock/Tadmor type barrier screws processing RPVC.

A number of researchers have pointed out a theoretical basis behind this “reverse” performance. In their book Extruder Principles and Operation, M.J. Stevens and J.A. Covas discussed the Menges/Klenk melting model, among others. They noted that the unique morphology of RPVC means it can often slide on metal surfaces rather than wetting them like most other polymers. They concluded that the exceptionally high viscosity of RPVC—and its different morphology—allow the solid bed to slide against the pushing flight with such pressure that it forces the melt pool forward to accumulate behind the flight, where the pressure is lower.

It would seem that this mechanism would only prevail with very high-viscosity polymers capable of developing sufficient shear stress and resultant pressure necessary to force the melt pool from the pushing side of the flight, where it is being naturally dragged due to the path of the helical flight. If the Menges/Klenk mechanism is in place, the flight clearance and the flight width become extra critical in the analysis of the melting process.

A crossing flight or dam like the Plastiscrew is successful with RPVC because it disrupts the melting pattern. That is, it rearranges the melt and solids as they pass over the clearance and allows the high viscosity of the polymer to complete melting, then mixes them to homogenize the temperature.

That could explain several of the inconsistencies in screw design for RPVC, including why rebuilt screws for RPVC can result in overheating and poor melt uniformity. It is also probably the reason barrier designs utilizing the Maillefer, or crossing-barrier, principle work somewhat better than parallel barrier flights for RPVC.

Related Content

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so the barrel appears to be turning clockwise around a stationary screw.

Read MoreInjection Molding: Focus on these Seven Areas to Set a Preventive Maintenance Schedule

Performing fundamental maintenance inspections frequently assures press longevity and process stability. Here’s a checklist to help you stay on top of seven key systems.

Read MoreThe Fundamentals of Polyethylene – Part 2: Density and Molecular Weight

PE properties can be adjusted either by changing the molecular weight or by altering the density. While this increases the possible combinations of properties, it also requires that the specification for the material be precise.

Read MoreBack to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More

.jpg;width=70;height=70;mode=crop)