In its corporate “Mission and Values” statement, custom injection molder and moldmaker GW Plastics says of its clientele, “Customers are the only reason for our existence and must be treated as such.” It was that spirit of service that brought GW to the central Mexican city of Querétaro in 2006—its first foray outside the U.S.—to better serve customers that had ventured south, and it is that same dedication that pushes the company to continuously improve that operation, which is now entering its 13th year.

“We try to cultivate long-term business relationships with our customer base,” explains Justino Barrientos, sales manager for GW Plastics Querétaro. “We don’t want to have a one-year relationship; we want to be there for many years and to keep growing that base.”

Featuring 26 highly standardized injection molding machines from Sumitomo Demag and Engel, ranging in clamp force from 60 to 660 tons, the approximately 52,000-ft2 operation has seen numerous changes over the last dozen years, with more in the works. When Plastics Technology visited in the fall of 2018, blueprints of the facility sat on plant manager Eric Olvera’s desk. The company was considering plans to boost capacity by 30% via an expansion and reconfiguration of its current space, which, without any new construction could house up to 31 injection machines, according to Olvera.

Olvera’s office on the second floor affords him a bird’s-eye view of GW’s operations in two ways—the first being a window overlooking the manufacturing operation, which in addition to molding includes mold machining and assembly; the second via a screen featuring live process feedback from the RJG sensors outfitted on every production tool running at the facility. Olvera’s own historical view of GW Plastics Querétaro extends back to its origins. When the facility opened in 2006 with six injection presses, he was the materials manager, working his way through the ranks in the intervening years to become the plant manager today.

Over that period, he’s seen numerous changes to GW and the Mexican market, with growth as an underlying constant. During that time, sales have nearly quadrupled as the company enjoyed sustained annual growth of 10% to 15% in Mexico. Globally, GW has operations in Vermont (two plants, including headquarters in Bethel), Texas, Arizona, Ireland and China, with the majority of its business in medical applications, followed by automotive. The Querétaro operation focuses largely on automotive, but medical business is growing, too. In Mexico, medical interest is expanding enough that plans are underway for a proposed expansion/reconfiguration including cleanroom and liquid silicone rubber (LSR) molding.

EVOLVING AND ADAPTING

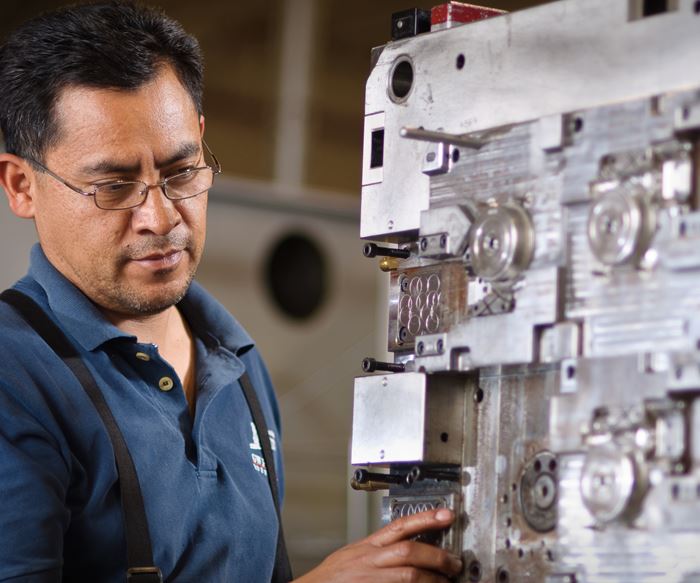

Olvera says GW’s customers’ demands, as well as the company’s capabilities, have evolved over time. “When we first started, the parts were simpler than those we’re doing now,” Olvera says. “Today we’re producing more complex parts with tighter tolerances.” Back in those early days, the operation focused strictly on molding, but now it has moved into assembly and highly customized secondary operations, including specialized leak testing for safety-critical automotive fuel-system components. Beyond insert molding and overmolding, secondary operations include ultrasonic welding and pad printing. Automation is applied on every machine. On the tooling side, the plant now runs more high-cavitation molds, ranging up to 64 cavities; and its in-house tool room has made it more self-sufficient for maintenance, repairs and some engineering changes. “It has been many years since we had to send a tool back to the U.S.,” explains Barrientos.

In addition to its process-monitoring technology, GW Plastics is a staunch proponent of RJG’s training offerings, with two certified Master Molders on its staff and the application of Scientific Molding principles throughout. On higher-cavitation tools, cavity separation is applied to segregate parts as they’re molded, with 100% inspection required on many jobs, given their safety-critical role in a car’s fuel, steering or brake systems.

Running on the floor when Plastics Technology visited was a system used to hold car windows in place, comprised of a metal stamping that must be preheated before overmolding. On another insert molding job, two Cognex cameras were in place to check for the presence and proper alignment of inserts; while an adjacent machine ran a gas-tank enclosure, where a terminal was inserted and overmolded. Post-molding operations for this job include testing for conductivity as well as leaks. The same RJG screen in Olvera’s office sat on the machine.

“All the machines and all the tools are connected to a computer, and every second we monitor what’s happening on the production floor.” Olvera says. “The process is monitored through the different sensors that we have installed on the machines, so at the end it will result in process stability which translates to good product.” GW Querétaro’s quality performance recorded a reject rate of 1 ppm in 2018, or better than Six Sigma standards.

The newest machine on the floor is an Engel duo 500, while above the plant floor the latest addition is an overhead crane. A fully enclosed and climate-controlled inspection room houses two coordinate measuring machines (CMMs). “We have a zero-defect philosophy,” Olvera says. “That is something we believe in highly.” Querétaro is certified to ISO 9001, ISO 13485 and IATF 16949. “The entire production facility operates in a climate-controlled environment following Good Manufacturing and 5S Practices, which further contributes to process stability and strong quality results,” Olvera notes.

FINDING & KEEPING TALENT

As its capabilities and its customers’ demands have increased, so has its competition, which Barrientos describes as “fierce.” One area where GW Plastics Querétaro finds itself battling other precision molders in Mexico is for workers. Including hourly and salaried staff, the facility has 129 employees, all of whom it must fight to keep.

“We believe in local people, and we have created extensive training programs, competitive wages, employee profit sharing, and benefit packages to make sure our workers feel comfortable and happy here,” Olvera says, “because we try to keep our people, work together with them. It has been hard in the last three years in the Querétaro area to maintain our people.” The company has risen to the challenge, however, holding to a single-digit turnover rate since 2017, according to Olvera.

In addition to special events, like a spring festival and Christmas holiday celebration that bring together employees and their families, the company has held onto workers by showing them a path to advance within the business, while recognizing them along the way. “Myself as an example,” Olvera says, “I started as a materials manager. Very much at first, we’re looking at what is the potential talent that we have inside. That helps when people feel they have a future with the company; that they can grow together.”

“That becomes motivation for the other employees,” Barrientos says. “They say, ‘OK, I can actually get to be a manager here if I work hard and get results.’ People are our most important asset. We must treat each other with respect and trust.”

“It is the people that are making the parts; it is the people that are touching the parts,” Olvera adds. “It’s important that they feel committed and happy to be working here. That is the basis of our business—we are people serving people at the end of the day.”

Barrientos concludes, “GW’s culture is rooted deeply in trust, respect, and integrity in all that we do. It starts at the top with Brenan Riehl, our CEO, who believes passionately in the power of ‘servant leadership,’ the philosophy of which runs throughout the organization, creating an environment of collaboration and teamwork.”

Related Content

How to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

Read MoreFor Extrusion and Injection-Blow Molders, Numerous Upgrades in Machines and Services

Uniloy is revising its machinery lines across the board and strengthening after-sales services in tooling maintenance, spare parts and tech service.

Read MoreMultilayer Solutions to Challenges in Blow Molding with PCR

For extrusion blow molders, challenges of price and availability of postconsumer recycled resins can be addressed with a variety of multilayer technologies, which also offer solutions to issues with color, processability, mechanical properties and chemical migration in PCR materials.

Read More‘Monomaterial’ Trend in Packaging and Beyond Will Only Thrive

In terms of sustainability measures, monomaterial structures are already making good headway and will evolve even further.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More