Foiling Flow Imbalances In Multi-Cavity Tools

In multi-cavity molding, attaining uniform and balanced flow of material to each cavity is a frequent challenge.

In multi-cavity molding, attaining uniform and balanced flow of material to each cavity is a frequent challenge. There are many well known causes of flow imbalances, such as differences in gate sizes and the shear patterns created in the runner system (as described by Beaumont). A lesser known culprit, which can also be more troublesome to diagnose, is temperature variations in hot-tip, thermally gated hot-runner systems.

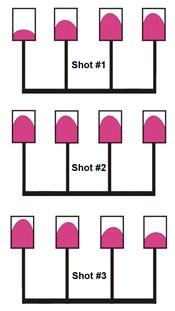

Temperature variations in the hot runner can not only produce short shots and flash in different cavities on the same shot, but also can cause continuous shot-to-shot variation in the cavities that experience these problems. In a four cavity tool, a molder may see a short shot in cavity number 1, flash in cavity number 4, and good parts in cavities 2 and 3. The cavities may see a different fill pattern on the very next shot, so that cavity 1 flashes, cavity 4 has a short shot, or perhaps every cavity is impacted in some way. The imbalance can be great, where one cavity is 50% filled in one shot and 100% the next shot. This variation can occur even with a two-cavity mold. The continuously changing imbalance can occur whether the application requires high or low injection pressure.

Minor temperature changes from one zone to another can create imbalances in filling within a matter of minutes, although the minimum amount of temperature change necessary to produce such variations has not been determined.

Temperature troubles

Changes in the hot-runner temperature have several sources. One source is oscillating temperatures in the hot drops due to the PID controller. In such a case, the temperature in each cavity rises and falls around the setpoint as the heaters turn on and off. The problem is that temperature cycles are different from cavity to cavity. For example, the temperature for cavity 1 may be rising while that in cavity 2 falls, resulting in easier flow into cavity 1, at least until cavity 1 starts cooling and cavity 2 begins to heat up. This variation results in longer-term trends, with one cavity exhibiting problems for several minutes at a time.

Another source of temperature-related flow imbalances is the formation of small frozen plugs in the gate at the end of each hot tip, much like a cold slug that forms on each shot at the tip of the machine nozzle. At the start of injection, these plugs must be “blasted through” before material flows into the cavities. The problem is that not all plugs get blasted through at the same time. The last cavity to blast open finishes flowing last, resulting in later filling, lower pressures, and possibly sinks or shorts. However, because it filled last, this cavity has less time to form a plug before the next shot. On this shot, the cavity fills sooner, resulting in higher pressures and possibly flash. This pattern keeps changing from cavity to cavity on each shot.

In this case, heating the tips for all cavities can result in less of a plug forming, which can produce more stable balance from shot to shot. However, it does not work in all cases, leaving the molder with the frustrating task of chasing a quality problem that is constantly shifting.

Cavity-pressure solution

Sometimes these problems can be overcome by changing temperature controllers, modifying the hot runner itself, or adjusting temperature-control settings. However, in too many cases, these are simply not options for the molder.

A better solution is to create a process that makes good parts despite the continuously changing imbalance. This method does not fix the root cause of temperature-related flow imbalances, and hence the imbalance will still be there. Rather, what we want to do is overcome the imbalances to make good parts.

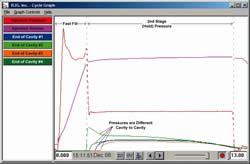

Creating more robust processes is made easier using pressure sensors in each cavity of the mold. Cavity-pressure data can be used to analyze the problem and then to evaluate the effectiveness of alternative solutions. It can also be used to provide closed-loop feedback to the press, transferring out of the injection phase when the correct pressure has been reached inside the mold. By adding cavity-pressure sensors, a user can see differences in peak pressures from cavity to cavity. Even more revealing is that the sensors can show which cavities filled first and to the highest pressures on each shot.

Very often, the first cavity to begin filling will continue filling before the press transfers to second-stage (packing) pressure. If the melt hits the end of the cavity during first-stage injection, the pressure will spike. This can result in problems such as flash.

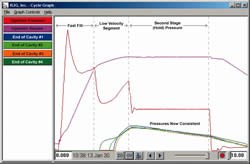

One solution is to reduce the injection velocity before the first cavity fills out, preventing any cavities from spiking in pressure. When parts are 80% to 90% full, a second low-velocity filling step is added to allow the cavities to finish filling without over-pressurizing the cavities. This low-velocity filling speed is often set at about 10% to 20% of the initial injection rate. This low velocity is maintained until the parts are packed to a desired pressure, at which point the press switches to the packing stage. This results in more uniform packing of all cavities.

One might expect that the cycle time would be extended when a low-velocity profile is added to the filling program, but the opposite is frequently the case. This is because the imbalanced process requires a hold time and cooling time sufficient for the last cavity to fill. By packing using velocity instead of pressure, the last cavity actually finishes filling sooner, resulting in overall cycle reduction.

The benefits of this approach are more consistent peak pressures inside the cavity from shot to shot. This results in more consistent part quality without sacrificing cycle time.

Mike Groleau is head of the Consulting and Training Group of RJG Inc., Traverse City, Mich. He has extensive experience in cavity-pressure data analysis, process-control strategies, and design of experiments (DOE) for injection molding He can be reached at (231) 947-3111.

Related Content

Custom Injection Molder Plugs into All Electric Machines

Formerly a showroom for early-aughts-era Van Dorn hydraulics, the newest additions to Drummond Industries’ transforming fleet are all-electric Niigata injection molding machines.

Read MoreInjection Compression Molding as Alternative to Thermoforming

Arburg will show its all-electric Allrounder 720 A press utilizing injection compression molding to create thin-wall IML cups from PP.

Read MoreIPEX Opens Injection Molding Facility in North Carolina

The pipe and fittings manufacturer’s new 200,000-square-foot facility represents a $200 million investment and will create 150 jobs.

Read MoreLS Mtron’s Outsized NPE2024 Presence Jump-Starts Ambitious North American Market Goals

The Korean maker of injection molding machines featured eight machines in its nearly 14,000-square-foot booth with additional presses at Yushin and Incoe’s booths, as it targets 20% market share.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More