LS Mtron’s Outsized NPE2024 Presence Jump-Starts Ambitious North American Market Goals

The Korean maker of injection molding machines featured eight machines in its nearly 14,000-square-foot booth with additional presses at Yushin and Incoe’s booths, as it targets 20% market share.

At the onset of the NPE2024, Peter Gardner, president of LS Injection Molding Machine North America and Paul Caprio, its president of sales, continuously fielded some version of the question: “Who is LS Mtron and where did it come from?”

“People would say, ‘Where did LS come from — you came out of the blue,’” Gardner said during LS Mtron’s NPE2024 press conference. “Well, that’s really not true; there’s a story.” Gardner, Caprio and LS Mtron’s global CEO, Chai-Ho Shin, endeavored to tell that story during the show.

The reality is that LS has been around since 1969. Back then, the Korean company that would go onto to become the global conglomerate LG launched an injection molding machine business. In 2003, LG established the LS Group (including LS Mtron) as a subsidiary. Today, LS Group employs 25,000 and generates annual sales of $30 billion. In 2018, LS acquired its North American distributor, a Japanese-based company that Gardner ran, and began heavily investing in the molding division there, including a booth at NPE2018. At the time, the relative new player had a market share of 1.5%. Fast forward six years and LS Mtron’s NPE booth is three times larger, dominating the front row of the West Hall and its market share at the end of 2023 had risen to 7.5%. The company is intent on maintaining that upward growth curve, with a stated goal of achieving 20% market share.

Shin, who earned his MBA from the University of Pennsylvania’s Wharton School 30 years ago, said at the time, he dreamed of returning to the states to run a company. He did so in March, when he was on hand for the opening of LS Tractors’ second U.S. production facility in Palestine, Texas. Located on 10.6 acres, the 210,000-square-foot facility also houses LS Mtron’s third U.S. tech center, providing live demonstrations, in-person training and mold trials for customers. It joins similar outposts in Wood Dale, Illinois, as well as facilities in Tijuana, Monterrey and Queretaro, Mexico. Investing $20 million in the site, LS Mtron notes that extensive renovations were completed to the facility, which has room for expansion and the potential for manufacturing LS Mtron molding machines as part of the company’s strategic plan.

To carry out that plan and achieve the market share goal, Shin said LS Mtron would need to expand its sales network, service and machine capacity. On the final point, the company opened a new factory in Jinju, South Korea. Located about 2 hours from LS Mtron’s main factory in Jeonju, the new 15,000-square-meter factory began operations in April and is scheduled to produce roughly 50 injection molding machines per month. The Jeonju factory has existing capacity of 130 machines per month, with an additional plant in China, which produces exclusively for that market, featuring capacity of 100 presses per month.

Caprio and Gardner noted that part of LS Mtron’s value proposition to the market is the fact that the company has long used its own machines to support the plastic molding needs of LG’s own companies, which are global leaders in appliances and electronics, as well as those of other global Korean companies in those markets and in automotive. From 2014 to 2023, LG purchased 1,390 injection molding machines from LS Mtron, including 41 in the U.S. and 120 in Mexico. “No other injection molding machine builder can make that connection,” Caprio says.

LS Mtron also says it can rely on the broader LG family of companies, which provide everything from servomotors and wiring to castings and even global shipping to deliver most new machines in all sizes in 100 days.

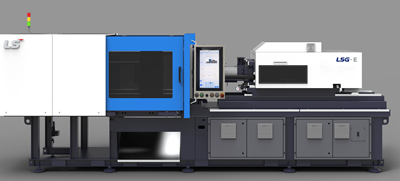

In its second ever NPE, LS Mtron went big. Source: Plastics Technology

Related Content

Completely Connected Molding

NPE2024: Medical, inmold labeling, core-back molding and Industry 4.0 technologies on display at Shibaura’s booth.

Read MoreIPEX Opens Injection Molding Facility in North Carolina

The pipe and fittings manufacturer’s new 200,000-square-foot facility represents a $200 million investment and will create 150 jobs.

Read MoreAbsolute Haitian Brings Next Generation of Presses to Orlando

NPE2024: Absolute Haitian says Generation 5 of the servo-hydraulic Haitian and electric Zhafir machines lines emphasize efficiency, performance and intelligence.

Read MoreTederic Promotes High Technology, Broader Market Presence

Four cells are running in its booth including a 1,300-ton multimaterial system highlighting its 2K capabilities.

Read MoreRead Next

Injection Molding: Servo-Hydraulic Line of Toggle-Style Machines Headed Stateside

Korea’s LS Mtron will be offering its WIZ-TA series of servo-hydraulic toggle injection molding machines in the U.S. with clamp forces ranging from 55 to 420 tons.

Read MoreLS Mtron Adds Three New Locations in the U.S.

The Korean maker of injection molding machines has added new operations in Texas, California and Georgia.

Read MoreNew Hybrid, All-Electric and Vertical Injection Molding Machines

NPE2024: In addition to new machines, LS Mtron is also launching a new 18-inch multitouch controller from Keba.

Read More