New Hybrid, All-Electric and Vertical Injection Molding Machines

NPE2024: In addition to new machines, LS Mtron is also launching a new 18-inch multitouch controller from Keba.

LS Mtron’s 10 machines and 13,500-ft2 NPE2024 booth — triple the space it occupied in 2018 — feature multiple new injection molding machines spanning an array of markets and process technologies. The company also has machines at the booths of show partners Yushin and Incoe. Targeting the electric vehicle (EV) battery market, the company’s LSG-VL vertical series features an 18-inch multitouch Keba controller and is available in clamping forces from 30 to 660 tons. Configurations include single- and shuttle-type vertical injection and single-, shuttle- and rotary-type horizontal versions. LS Mtron says cooling water, tank size and oil lines have been minimized to reduce operating and maintenance costs, and there is optional electric injection.

At the show, a 170-ton LSG-V machine is molding an EV component. LS Mtron says the LSG-V series enables energy savings of 65% to 70% because of its servo-pump system. The larger Keba controller features cycle analysis, unit conversion and a memo function that enables users to associate data with a specific mold. Users can also customize password controls and apply multiple units — psi, inches, mm — and languages.

The Keba controller is also being demonstrated on LS Mtron’s ONE series of hybrid machines, which have been optimized for high-precision automotive parts molding with the ability to run heavier molds and produce large parts with detailed surfaces. In Orlando, a ONE-1400 will mold the rear door side trim for a Hyundai vehicle. LS Mtron says benefits of the ONE series include a no-lubrication sliding bushing for 40% improvement on tiebar “drooping” or sag, and a quick barrel-change system, with optional one-touch tiebar separation, eliminating disassembly/reassembly and making it easier to replace molds in low ceiling spaces.

LS Mtron is also demonstrating its sandwich injection molding via its Piggyback Multi Component (PMC) technology, molding surface layers from virgin material with recycled resin in the core.

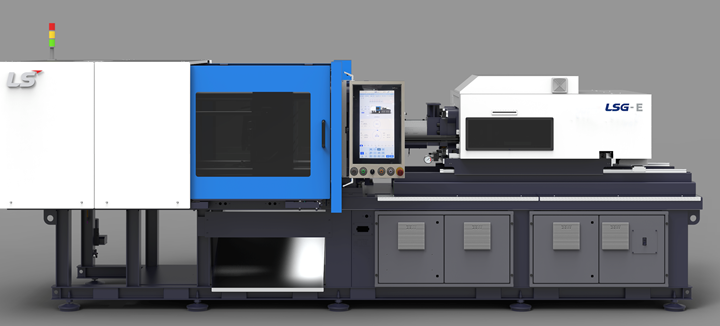

The all-electric LSG-E will add a 1,500-ton press in 2024. Source: LS Mtron

Additional new machine lines include the all-electric LSG-E, ranging in clamp force from 35 to 950 tons, with plans for a new 1,500-ton model to be introduced in 2024. Featuring high-stiffness platens with a five-point toggle design for high-speed clamping and high-intensity injection, LS Mtron says the LSG-E is well suited for precision applications. Features include a 13% to 27% increase in injection volume and injection speed of 300 mm/sec. For models ranging from 90 to 440 tons, there is an extended tie bar distance and extended daylight option available.

The LSG-H servo-hydraulic line, with oil-leak prevention, is available with clamp forces from 500 to 3,600 tons. The machine features 1,000 mm/sec mold open and close speeds via a proportional valve, and a quick-change barrel and screw-replacement system for the “Y” screw or smallest one, as well as “A” and “B” screw sizes. In terms of consistency, LS Mtron says the machine has shown shot-to-shot, part-weight deviation of just 0.07%.

The LSG-H line of servo-hydraulic injection molding machines has clamp forces ranging from 500 to 3,600 tons. Source: LS Mtron

Related Content

-

U.S. Debut for Slimmed Down Electric Machine

NPE2024: Arburg’s debut of the 310-ton Allrounder 720 E Golden Electric extends the tonnage range of the electric series and marks the first global press premiere outside of Germany.

-

LS Mtron’s Outsized NPE2024 Presence Jump-Starts Ambitious North American Market Goals

The Korean maker of injection molding machines featured eight machines in its nearly 14,000-square-foot booth with additional presses at Yushin and Incoe’s booths, as it targets 20% market share.

-

Tederic Promotes High Technology, Broader Market Presence

Four cells are running in its booth including a 1,300-ton multimaterial system highlighting its 2K capabilities.