Follow These Guidelines to Select the Right Pelletizing System

Which pelletizing system is right for your application? Is the one you’re using today necessarily the right choice for tomorrow? Here’s is an analysis that can help you decide among the three major options.

Companies planning to invest in pelletizing equipment can select the right system by making a thorough inventory of their operational and application needs, in addition to the basic consideration of cost. Three major types of pelletizing system are available, each with a distinctly different range of strengths and weaknesses. With the growth of the plastics industry and the continual emergence of new requirements in the marketplace, even a company that has long used a particular system may need to consider an alternative when the time comes to add capacity.

Pelletizers are essential components in resin manufacture, compounding, masterbatch production, and recycling. A high-volume system that is appropriate for a polymerization plant will be very different from one that suits the needs of a toll compounder. One that can produce micropellets for use in masterbatch may not be the best choice for processing post-consumer regrind. What follows is an evaluation of each type.

UNDERWATER PELLETIZERS

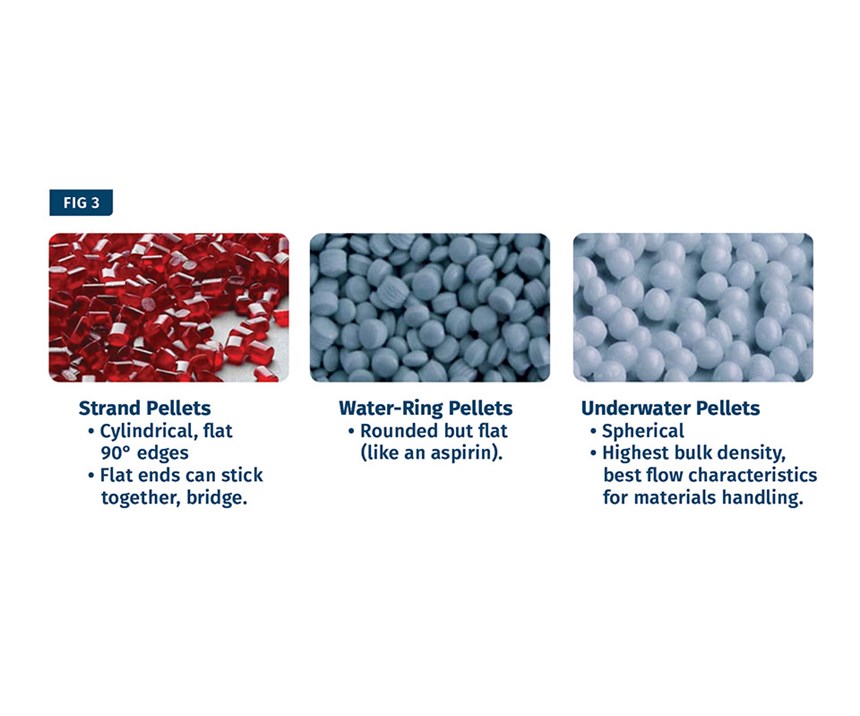

The underwater pelletizer (UWP) is a die-face pelletizer. This means that molten polymer is cut into pellets as it exits the die holes, which are arranged in a circular pattern in a round die. The crucial difference from the water-ring pelletizer (also a die-face pelletizer) is that the cutting chamber is completely filled with process water, so that the polymer drops are immersed in water as they exit the die holes. Because of forces that minimize surface tension, each drop takes on a spherical shape, which is unique to UWPs.

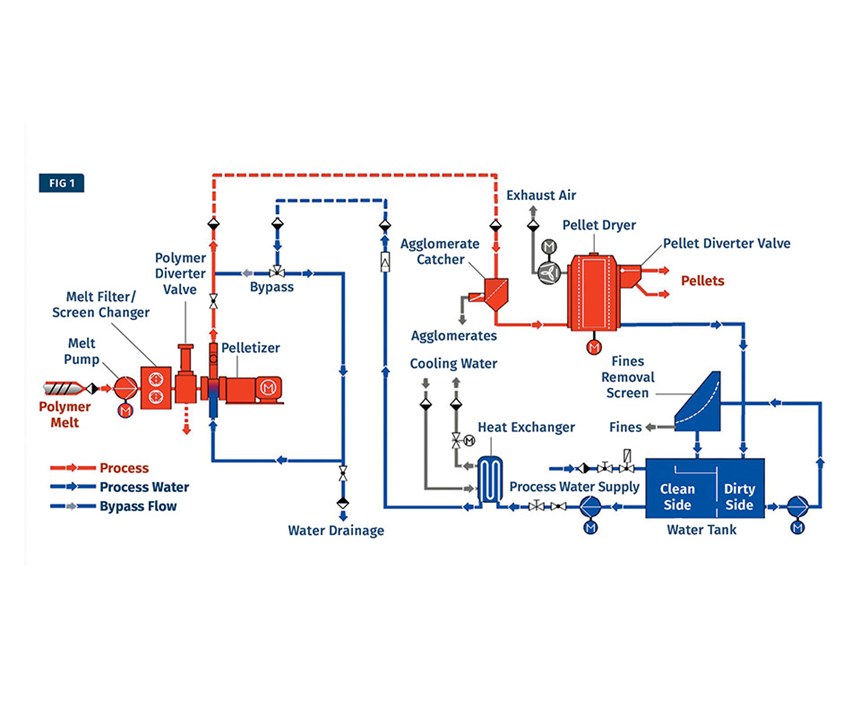

The process water transports the spherical pellets from the cutting chamber to an agglomerate catcher (which removes clumps of plastic) and then to a centrifugal dryer. The pellets enter the dryer at the bottom of the unit, and a rotating shaft with lifting vanes de-waters the pellets, which exit the dryer at the top. A similar type of dryer is used with the water-ring pelletizer.

As with other pelletizing systems, the cooling water in the UWP is supplied by a process-water unit, which tempers the water—that is, mixes hot and cold water to ensure a constant temperature—and filters out dust and fines. Water temperature must be carefully controlled and adjusted according to the properties of the polymer being pelletized. Failure to do so can lead to malformed pellets or process disruptions.

In UWPs, all cooling water is transported to and from the cutting chamber by means of pipes, making unnecessary water troughs or water slides found in other pelletizing systems. As a result, the centrifugal pellet dryer and water-treatment equipment can be installed at some distance from the pelletizer—in another room, for example, or on another floor.

Another feature made possible by water piping is the water bypass system, which allows water to continue circulating to maintain the required temperature while diverting flow from the cutting chamber. This enables the operator to disconnect the pelletizer from the cutting chamber in order to perform tasks such as changing the cutter head.

The bypass system works in coordination with a polymer diverter valve for stopping and starting polymer flow into the die holes. Before startup of the pelletizer, the valve is switched to the “production” position for flushing of the die plate. Next, with the valve in “divert” position, polymer can be cleaned out of the cutting chamber. Finally, the pelletizer is re-coupled to the cutting chamber; the water bypass switches to send water into the cutting chamber; the diverter valve is switched to production position; and pelletizing begins. The whole process is automated, takes place in seconds, and is initiated by means of an on/off button in the PLC controller.

Several options are available for controlling the pressure of the cutting blades against the die plate. Among these are a manual system, in which the operator uses a hand wheel, and PLC-controlled hydraulic systems. Other options include spring-loaded and pneumatically actuated systems.

Process-water systems are available with varying degrees of capability. An entry-level system that is completely skid-mounted has a capacity of up to 4400 lb/hr and can be provided with an optional belt filter for continuous automated filtration of fines down to 150 µ. More elaborate systems provide automated self-cleaning, filter down to 70 µ, and have capacities as great as 77,000 lb/hr.

As the foregoing features suggest, the UWP is the most complex pelletizing system and entails the greatest investment cost. In turn, it offers advantages over other pelletizing systems in these areas:

● Automation. The UWP has the greatest scope for automation, with PLC control governing many of its features. Functions such as blade sharpening and in-line die-plate grinding can be pre-programed, minimizing downtime.

● Throughput. UWPs can be designed for throughput capacities up to 70,000/hr, vs. 44,000 lb/hr for strand pelletizers, and 11,000 lb/hr for water-ring pelletizers.

● Versatility. The UWP can process virtually any polymer and can be used for the full range of applications, including compounding, hot melts, masterbatches, polymerization, recycling, and reclaim. Strand pelletizers can be used for all of these applications except for hot melts. Water-ring pelletizers, owing to their lower throughput capacity and limitation to high-melt-strength materials, are chiefly recommended for recycling and reclaim.

● Blade life. Extended through control over cutter pressure.

● Range of pellet diameters. Wide, and includes micropellets, which are used in production of masterbatches and expandable polystyrene, as well as in rotomolding.

● Pellet consistency and geometry. In addition to being more uniform in size, pellets made in UWPs have a spherical shape that enhances flow into hoppers and feed throats and increases bulk density.

● Dust and fines. Low as a result of polymer being cut in molten form.

● Integration with upstream equipment. The operator can use a single interface on the pelletizing system to access the extruder, feeding equipment, screen changer, and melt pump.

● Footprint. Small in comparison with strand pelletizers.

Along with cost and complexity, the UWP system has another disadvantage: the potential for die “freeze-off” when running certain products. This occurs when a process variation upstream of the pelletizer causes reduced or uneven polymer flow at the die plate, so that the polymer solidifies in the die holes. Freeze-off can cause distortions or non-uniformities in the pellets produced. A consistent and high level of melt pressure at the die plate is essential for preventing freeze-off.

WATER-RING PELLETIZERS

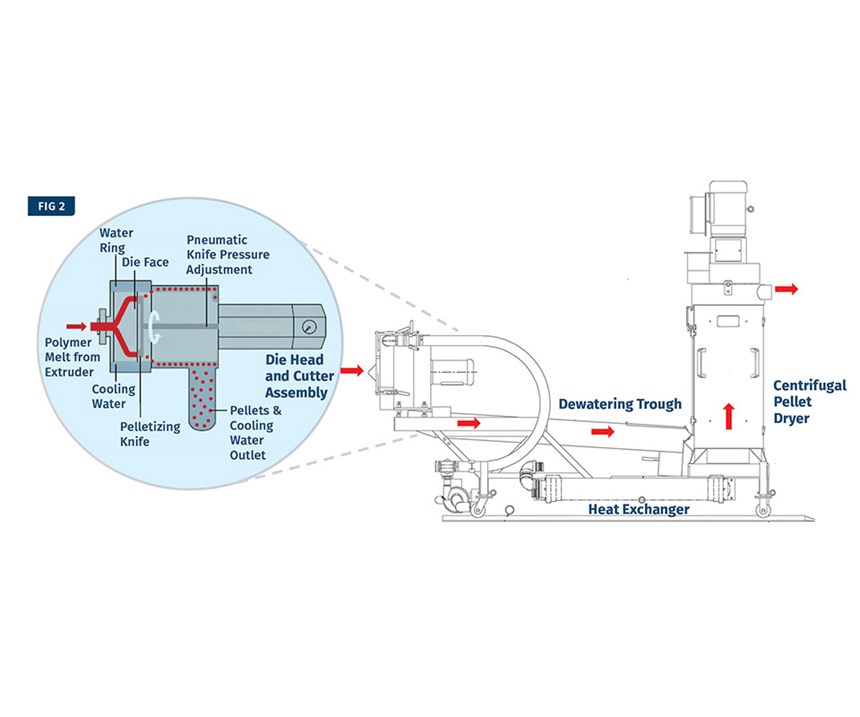

In water ring pelletizers (WRPs), as in UWPs, molten polymer flows into multiple holes arranged in a circular pattern in a die plate and is cut into pellets as it emerges from the die face. The cutting is accomplished by a series of rotating knives that are also arranged in a circular pattern. The die face is made of hardened metal, so that wear takes place mainly in the knives. Pressure is hydraulically applied to the cutting assembly to ensure proper contact with the die face.

WRPs produce pellets that are rounded but flat, similar to aspirin tablets. As the polymer exits the die holes and is cut by the rotating knives, the resulting pellets are thrown outward into a ring of water that is fed tangentially into the cutting chamber. The water cools the pellets and transports them to a water trough for further cooling and transportation to a centrifugal dryer that operates in the manner already described. Water is returned to a tempering and filtration system and recycled into the pelletizing process.

The WRP is the most compact of the three major pelletizing processes and provides a degree of automation. One operator can easily control the system, using a pushbutton control to stop and start the system and adjusting the cutter rpm to control pellet size. The system costs less than UWPs. It is significantly less sensitive to process variations such as melt temperature and pressure and does not present problems of die freeze-off.

Because pellets are cut from the molten polymer before it encounters cooling water, the WRP is limited chiefly to processing high-melt-strength materials such as polyolefins and polystyrene. The process is particularly unsuited for high-heat or sticky materials. There are also capacity limitations in comparison with UWPs.

STRAND PELLETIZERS

In strand pelletizing, polymer is cut into pellets after it has cooled and solidified. By its nature, this system is operated in-line with extrusion. Molten polymer is metered into a strand die that is much like a sheet die except that the material exits the die through multiple holes, each forming a strand of polymer. The strands enter a water bath or trough, where they are cooled, then are dried by a de-watering unit or air knife, and finally are fed into a strand pelletizer, where they are cut into cylindrical pellets. A disadvantage of this pellet shape is that the flat ends of the cylinders can stick together and cause bridging.

After cutting, the pellets fall into a classifier, which removes oversized pellets or agglomerates and conveys the rest of the pellets downstream.

In addition to being the lowest in cost, strand pelletizing can be used with a wide range of polymers, is simpler to use than other pelletizing systems, provides easier access to component surfaces for cleaning and color changes, and facilitates polymer changeovers through rapid replacement of cutting components. Thus it is particularly appropriate for toll compounders and other companies that make short runs with frequent job changes.

The strand pelletizer has little scope for automation and is more labor-intensive than other pelletizing systems. Consider, for example, the work involved in stringing up to 75 strands over and under guide rolls with each new job startup. Strand pelletizers also are limited as to pellet size, with the small pellets required in some applications being difficult to obtain without strand breakage. Two other weaknesses derive from cutting pellets from solidified strands: there is a greater potential for cutter wear and for generation of dust and fines than with other pelletizing systems. Strand pelletizers also are more readily affected by process variations, which can cause dropped strands and other difficulties. And finally, the need for a water bath means strand pelletizers have a larger footprint on the factory floor.

Some of these weaknesses of this “dry-cut” process can be mitigated with an alternative “wet-cut” strand pelletizer called a water-slide system. Instead of a water bath, the strands enter a water slide, in which spray nozzles cool the strands and provide a cascading water flow that moves the strands toward the pelletizer. Instead of using an air knife, this system reroutes process water away from the strands just before pelletizing and then lets it rejoin the pellet stream just afterward to form a pellet/water slurry, which further cools the polymer. The slurry enters a centrifugal pellet dryer at the bottom of the unit, and a rotating shaft with lifting vanes de-waters the pellets, which exit the dryer at the top.

In the water-slide system, because pellets are cut from strands that are still wet and softer than those in the water-bath system, there is less cutter wear. The water-slide system also provides more scope for automation through greater control over process-water conditions. In addition, there is a capability for “self-stranding,” in that dropped strands are replaced as strands are fed into the water slide, reducing need for operator intervention. On the other hand, the drying process generates additional dust and fines, requiring a more sophisticated filtration technique in the process-water system. This is also the case with centrifugal pellet dryers used with water-ring and underwater pelletizers.

FACTORS AFFECTING PELLETIZER CHOICE

This discussion of the capabilities and requirements of the major types of pelletizer systems makes it apparent that for every application the range of pelletizers varies from those that are ideally suited to those that are totally inappropriate. The differences among the types of systems are summarized in three accompanying tables.

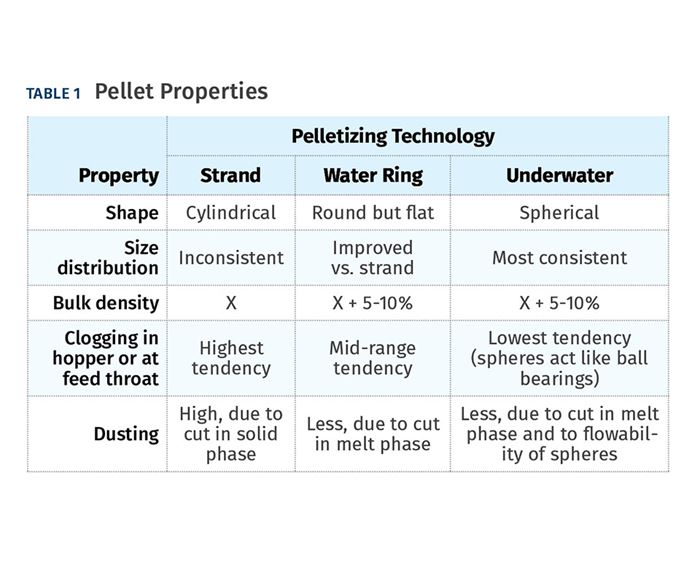

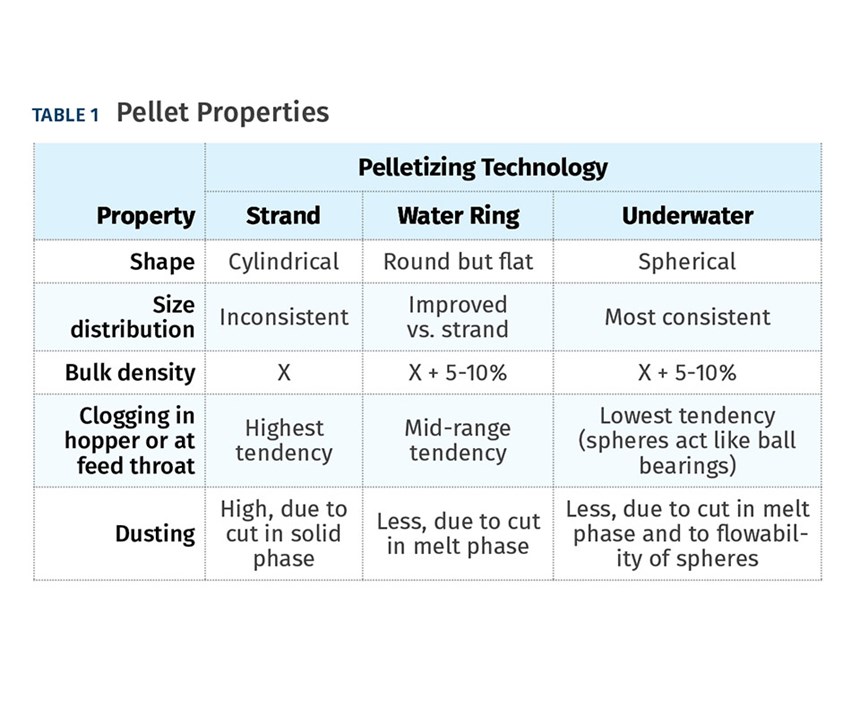

As shown in Table 1, the pellets produced in the available systems differ widely in shape, consistency, flow properties, and generation of dust and fines. These properties substantially affect pellet performance in material-handling systems downstream of the pelletizing process.

The comparison of production factors in Table 2 shows even wider differences among the available pelletizing systems. The chief differences involve capital investment, throughput capability, scope for automation, and flexibility of deployment. They determine whether a system is right for a high-volume polymerization plant, a custom compounder, or an in-house compounder with a limited budget and a low tolerance for system complexity.

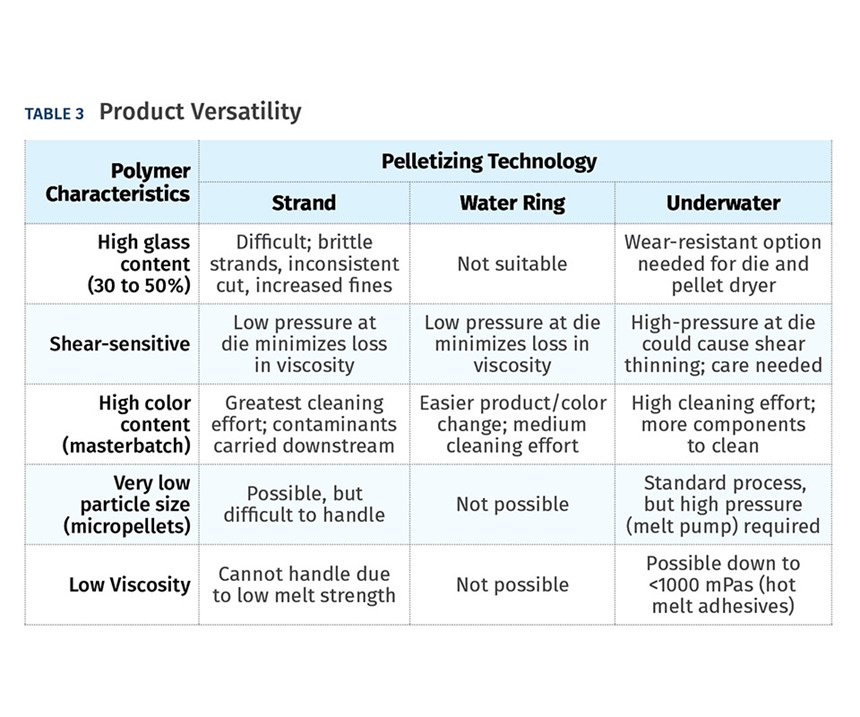

Pelletizers also vary widely in the types of polymers that they are able to process effectively, as shown in Table 3. Only one system, the underwater pelletizer, is capable of handling virtually any type of polymer.

The marketplace has room for all of the systems discussed. There exists a vast potential for pelletizing systems, driven by strong global growth in consumption of plastic products, a flourishing recycling industry, and a gathering trend toward localized production of resins, compounds and additives. To meet this demand, suppliers of pelletizing systems can be counted on to develop improved and innovative equipment.

EDITOR’S NOTE: This article was adapted from a presentation the author gave at Plastics Technology’s Extrusion 2018 Conference. For information about Plastics Technology’s Extrusion 2019 conference, click here.

ABOUT THE AUTHOR Merritt H. Christian is pelletizing market-development manager for Nordson Corp.’s Polymer Processing Systems business. He is responsible for sales in North and South America of Nordson’s BKG brand of underwater and water-ring pelletizers.He joined Nordson in 2016 after four years at SK Chemicals America, where he was in charge of business development for Advance Polymer Solutions. He has also worked for Amoco, Owens Corning, PolyOne, DSM, and Sukano Polymers. Contact: merritt.christian@nordson.com; nordsonpolymerprocessing.com.

Read Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More