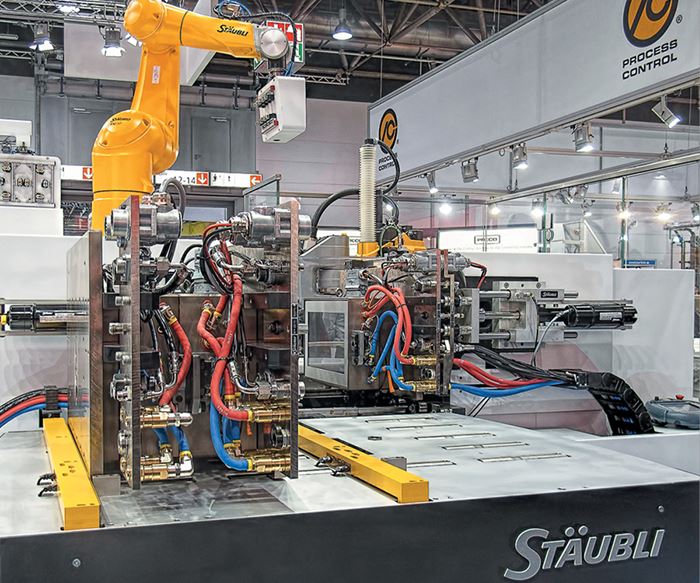

Fully Automatic Mold Change In Under 2 Min

Used in production with large presses.

At K 2016 in Dusseldorf, Staubli (U.S. office in Duncan, S.C.) demonstrated complete hands-off mold changing in less than 2 min, and company spokesmen said the system can get that down to 1 min. A mold table on rails carried a preheated mold into position beside the press. A sensor in the cart read the mold setup parameters from a chip in the mold. For the mold already in the press, all power and data connections were disconnected automatically within 3 sec. A single manual lock disconnected all water lines. Ejectors retracted automatically, and the Staubli magnetic plates declamped the mold in another 3 sec. The mold then slid out of the machine onto the cart, which indexed forward so the new mold could slide into place, clamp on magnetically, and make all the utilities connections. The final step was automatic exchange of robot grippers for the new job.

Staubli sources said this system is being used at a new Plastic Omnium plant in Mexico, where several rail-mounted mold tables exchange 60-ton molds in 3700-ton presses in under 2 min.

Related Content

-

Why Shoulder Bolts Are Too Important to Ignore (Part 2)

Follow these tips and tricks for a better design.

-

Where and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.

-

Back to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.