Get Smarter About Melt Filtration

As quality specifications become tighter and the need to use more recycled materials becomes more prominent, more and more extrusion processors are examining their options in melt-filtration technology. Here's some help in evaluating your options.

As quality specifications become tighter and the need to use more recycled materials becomes more prominent, more and more extrusion processors are examining their options in melt-filtration technology. There are three basic reasons why you may need melt filtration:

1. Product quality specifications mandate visual or mechanical properties that cannot be maintained without filtration.

2. Downstream equipment may become damaged by contaminants in the melt.

3. Additional melt pressure is needed to improve melt quality.

It is likely that most extrusion processors will fit into one of the above categories, and that they will find a simple breaker plate unsatisfactory due to the time required to disassemble and reassemble the device. The alternatives considered here are various types of screen changers, though other types of filters may be used for special purposes, like high output rates and very tight filtration requirements.

TYPES OF SCREEN CHANGERS

The basic types of screen changers fall into one of four categories: discontinuous, semi-continuous, continuous, and continuous with backflushing.

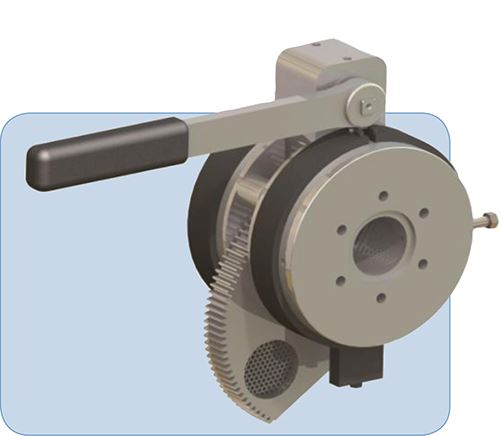

So-called manual, discontinuous screen changers are the lowest-cost type. They utilize a lever, ratchet, or screw device to move the melt filters in and out of the flow. These screen changers are called discontinuous because they require the line to be stopped for a screen change. The positive characteristics are low cost and straight-through, low-pressure-loss flow design; while the obvious disadvantage is complete process interruption when screens need to be changed.

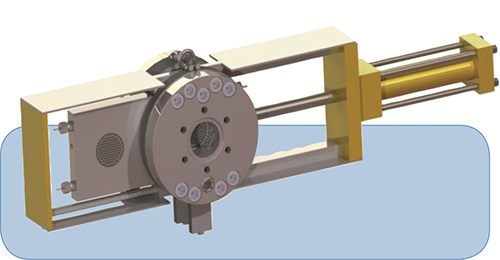

The semi-continuous hydraulic slide-plate screen changer utilizes a fast-acting hydraulic cylinder to move the screen packs in and out of the melt flow. These kinds of units can be defined as semi-continuous because they allow screen changing without stopping the line, but during that process some off-specification material will be produced. The advantages to this type of unit are relatively low cost, straight-through, low-pressure-loss design, and screen changing without stopping the line. The hydraulic slide plate is a low-cost way to provide screen changing “on the fly” with the disadvantage being the production of some off-spec material due to momentary interruption and air entrainment.

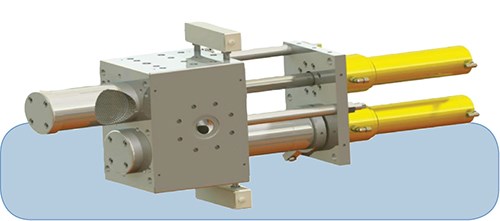

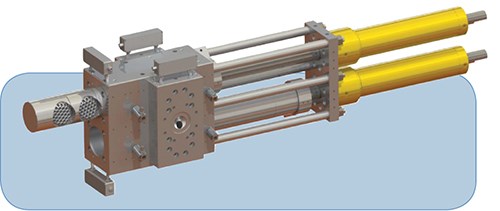

Continuous piston-type screen changers come in single- or multiple-piston styles and typically employ more than one breaker plate in the flow so that each breaker plate can be removed, one at a time, for screen changing without interrupting the flow. Piston units also include a venting/de-aeration process to ensure that no entrained air enters the flow and creates off-spec product.

These screen changers have been built since the 1960s and are well proven in the industry. They contain no seals, relying on the close fit between the piston and housing for sealing. Although there is some flow change as one or more of the screens are removed for changing, the total flow area is generally larger than comparable discontinuous, or semi-continuous designs. This larger screen area compensates for the reduced flow area while the screens are being changed.

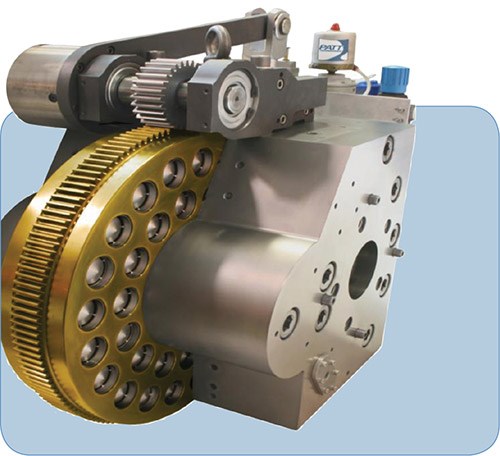

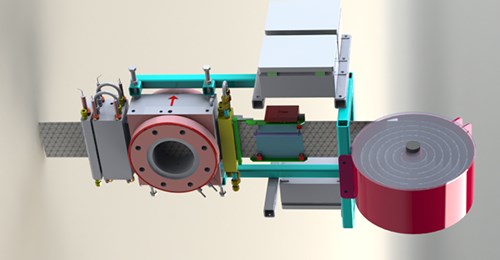

Continuous, rotary screen changers use a moving circular disk containing multiple screen packs so that a relatively equal amount of filtration area is exposed to flow at all times, allowing only a very small change in pressure when the screens are indexed. Relatively constant pressure is the primary advantage of these units. Rotary screen changers have been around since the late 1980s, but have been well refined since the mid to late 1990s. These screen changers have no active seals and rely on the close fit between the rotary disk and the housing for sealing. Their biggest disadvantages are the relatively high initial cost and the requirement to maintain proper fit of the screen bearing disk against the housing over a wide range of extruded products.

Continuous-belt screen changers use a screen roll that is indexed by process flow pressure exerted on a melt plug. The temperature is increased on the melt plug when screen surface renewal is needed and movement is stopped by decreasing the temperature of the melt plug once the new screen area is in place. These screen changers have been around since the 1960s, but application has been limited. The advantages of this type are straight-through, low-pressure design and relatively constant flow and pressure. The largest disadvantages are the sensitivity to various polymer characteristics and limitation on high contamination levels, since there is a restriction on the speed that the screen can advance without breaching the polymer seal.

Continuous backflushing screen changers are typically a variation of either the piston or rotary type, which allows the process pressure to be reversed through the screens to dislodge contaminants. Pressure and flow for backflushing can also be generated by hydraulic cylinders that accumulate material from the flow to use for backflushing. Backflush screen changers are typically only used where recycled or very dirty materials are processed.

FOUR SCENARIOS

Since equipment is the lowest cost part of the process, compared with plant overhead, labor, and raw materials, considerable care should be taken in the selection of the best filtration solution.

While a particular type of screen changer is not indicated by process type, it is true that the selection of a specific type of screen changer may be more prevalent in one process over another.

Following are a number of hypothetical applications and the process used to select the appropriate screen changer.

Application: Custom profile

Extruder type/size: 3.5-in. single screw

Screen mesh: 100

Rate: 600 lb/hr maximum

Polymer: PP, HIPS, ABS, PE

Time between line shutdowns: Maximum 24 hr

Time between screen changes: 48 hr

Screen changer selection: Manual, lever type, about 4-in. diam.

This is a relatively small extruder with clean material, indicated by the need to change screens at most every 48 hr, while the line only runs for a maximum of 24 hr between normal shutdowns. Extruder size is small enough that manual shifting is possible. Screens a little larger than screw size were selected to permit pull-through.

Application: Custom sheet

Extruder type/size: 6-in. single screw

Screen mesh: 100

Rate: 2000 lb/hr maximum

Polymer: PP, HIPS, ABS, PE

Time between line shutdowns: Maximum 24 hr

Time between screen changes: 48 hr

Screen changer selection: Hydraulic slide plate type, 6.5 in.

This is a relatively large extruder with clean material, as indicated by the need to change screens at most every 48 hr, while the line only runs up to 24 hr between normal shutdowns. Extruder size is too large to easily shift a manual screen changer. Screens a little larger than screw size were selected to permit pull-through.

Application: Blown film with 50% recycle

Extruder type/size: 6-in. single screw

Screen mesh: 100

Rate: 2000 lb/hr maximum

Polymer: LLDPE

Time between line shutdowns: Two weeks

Time between screen changes: 8 hr

Screen changer selection: Continuous type with approximately 8 in. or more of screen in the melt flow.

This is a relatively large extruder with relatively dirty material, indicated by need to change screens every 8 hr while the line runs for up to 2 weeks between normal shutdowns. It is too expensive to accept lost production when screens are changed. A slightly oversized unit was specified to reduce screen pressure loss with dirty material.

Application: Underwater pelletizing with 80% recycle

Extruder type/size: 6-in. single screw

Screen mesh: 100

Rate: 2000 lb/hr maximum

Polymer: HIPS

Time between line shutdowns: 48 hr

Time between screen changes: 30 min.

Screen changer selection: Continuous, backflushing type with approximately 8 in. or more of screen in the melt flow.

This is a relatively large extruder with relatively dirty material, indicated by need to change screens every 30 min while line runs for up to 48 hr between normal shutdowns. It is too expensive to accept lost production when screens are changed. The backflush, self-cleaning feature allows each screen to be re used approximately 20 times, resulting in significant reduction in screen and labor cost.

USE REAL WORLD DATA

Of course, choices may become blurred because of borderline data, causing selection to become less precise. Sometimes economic resources are insufficient to purchase the best unit for the job. Other considerations may be familiarity (or lack of familiarity) with a particular type of filtration equipment, and maintenance sophistication at the plant level. It is unwise to specify sophisticated computer-controlled equipment where other plant equipment is much less complex and maintenance personnel and operators may not be able to cope. In this case, selection should be skewed toward a simpler solution.

It is always best to demand existing operating data for scaling up rather than relying on speculation in cases other than routine filtration of virgin resins at screen mesh sizes of 200 or less. In such cases, if a screen changer must be sized only from speculative data, consider applying a minimum 25% safety factor.

The equipment supplier should be required to make a size recommendation and then you should perform your own analysis to confirm appropriate sizing. That way, you will have the advantage of independent analyses and, best of all, there is no additional cost.

Learn the difference between price and cost. Be sure to take into consideration all of the variables and look at all the factors to determine the real cost of ownership for the screen changer. Some of the hidden variables to consider may be:

•Product quality.

•Maintenance, time and cost of parts.

•Process downtime and cost.

•Life expectancy for the equipment and amortized cost of ownership.

•Cost and availability of filtration media.

•Pressure loss and effect on line output and product quality.

•Operator safety.

•Required operator intervention and labor cost.

If all of these and other factors are taken into consideration, you can expect a much better return on investment.

Related Content

Ultrasonic Welding: Tips, Techniques, and Troubleshooting

In this collection of content, we provide expert advice on welding from some of the leading authorities in the field, with tips on such matters as controls, as well as insights on how to solve common problems in welding.

Read MoreBozzelli’s Guide To Specifying a Dryer

Here's a list of 17 things to do when looking for new drying equipment.

Read MoreFive Quick Steps Toward Better Blending

Rising costs of resins and additives, along with higher demands for quality and use of regrind, place a premium on proficient blending. Here are some steps to get you there.

Read MoreThe Importance of Barrel Heat and Melt Temperature

Barrel temperature may impact melting in the case of very small extruders running very slowly. Otherwise, melting is mainly the result of shear heating of the polymer.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More