Glass Reinforcement Opens New Doors For PVDF Fluoropolymer

Glass fiber is a new partner for this resin. A wider range of applications beckons.

Some interesting new applications are emerging for polyvinyldene fluoride (PVDF), according to Arkema, King of Prussia, Pa. The trigger is its development of glass-reinforced grades for applications that can use a stiffer, stronger, and higher temperature-resistant fluoropolymer, along with other exceptional properties. The recently unveiled product line combining PVDF with glass fibers is the Kynar UHM fluoropolymer series.

A broadly chemical-resistant material, PVDF reportedly is also the most creep-resistant commercial fluoropolymer and is highly abrasion resistant. It boasts long-term UV stability and supports a 150 C (302 F) UL Relative Thermal Index (RTI) rating. Despite its long-term and widespread use in unfilled form as a coating for applications ranging from fluid-handling components to more recent major growth in outdoor exposed metal building components, Very little work has been done on reinforcing PVDF to increase its strength and stiffness for applications where plastics continue to find design niches that are traditionally served by metals.

“PVDF compounds utilizing carbon fiber were developed years ago, and while they provide novel performance improvements in strength and tolerance stability, there is the high product cost issue associated with the technology,” says David Seiler, Arkema Americas’ industrial business manager and global advisor for fluoropolymers. Unlike many other resins that are offered in glass-filled versions, glass-filled PVDF technology has not been highly developed until now, he explains.

Articles currently made from neat PVDF that could be further enhanced with glass reinforcements include pipes, fittings, valves, nozzles, clamps, fluid connectors, tapes/films, pump parts, dump-tower packing, tanks, wires, connectors, and filaments. Because the new Kynar UHM series is highly flame resistant, very strong and stiff, as well as creep resistant at elevated temperatures, Arkema envisions significant improvements could be realized, with the appropriate R&D, in a number of uses.

According to Seiler, these could include pump assemblies that maintain high-temperature service conditions better than ever; plastic valves that can be designed to be turned on and off frequently without distortion; and tower packing that does not readily sag over time.

Yet other products could include cable insulation exposed to high heat that does not thin out or drip off of the protected cable; plastic products designed for prolonged system integrity and safety in the event of direct fire exposure, such as products for military and aircraft applications; clamping devices that can apply high force; and strong filaments with high chemical resistance that can be used to wrap products for high-pressure resistance.

PROCESSING & PROPERTY IMPROVEMENTS

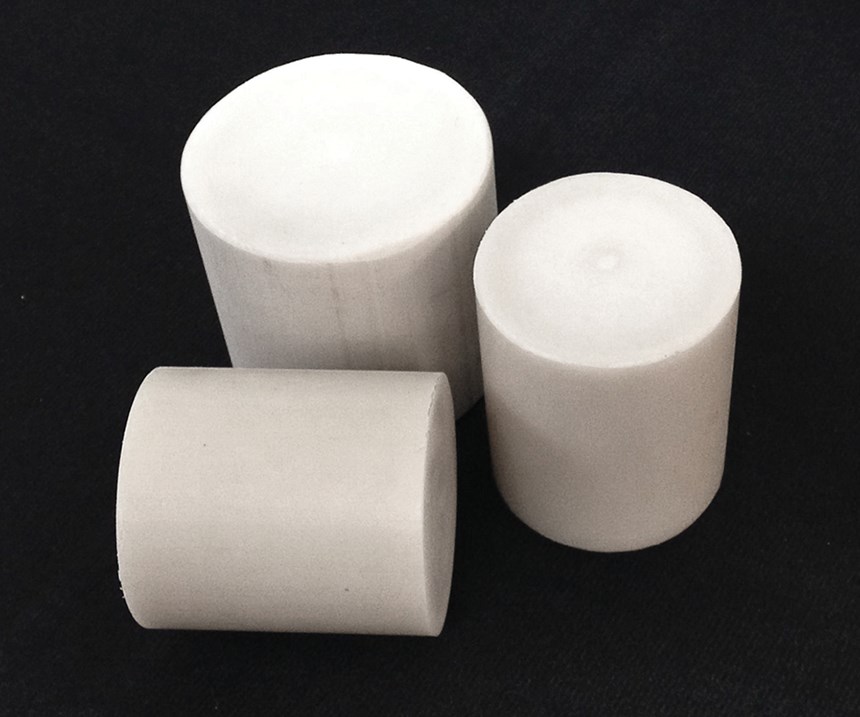

PVDF generally exhibits ease of processing with typical conditions and equipment used for PP, PVC, and nylon. Compounding glass fibers into PVDF is not unusually difficult, says Seiler. Similarly, producing injection molded parts like pump components, fittings, valves, or dump-tower packing; or extruded shapes like rods, sheets, or pipes is not considered more difficult than with other glass-filled plastics.

The new Kynar UHM fluoropolymer compounds are made with a PVDF base resin that has a relatively high melt-flow rate (MFR) because keeping the processing temperatures lower is a safer procedure with glass-filled fluoropolymers, explains Seiler. “While the addition of glass fiber drives up the viscosity of the polymer blend, the recommended polymer composite’s MFR still remains in the range where it can be injection molded at temperatures below 210 C (410 F) and extruded at or below 240 C (464 F).”

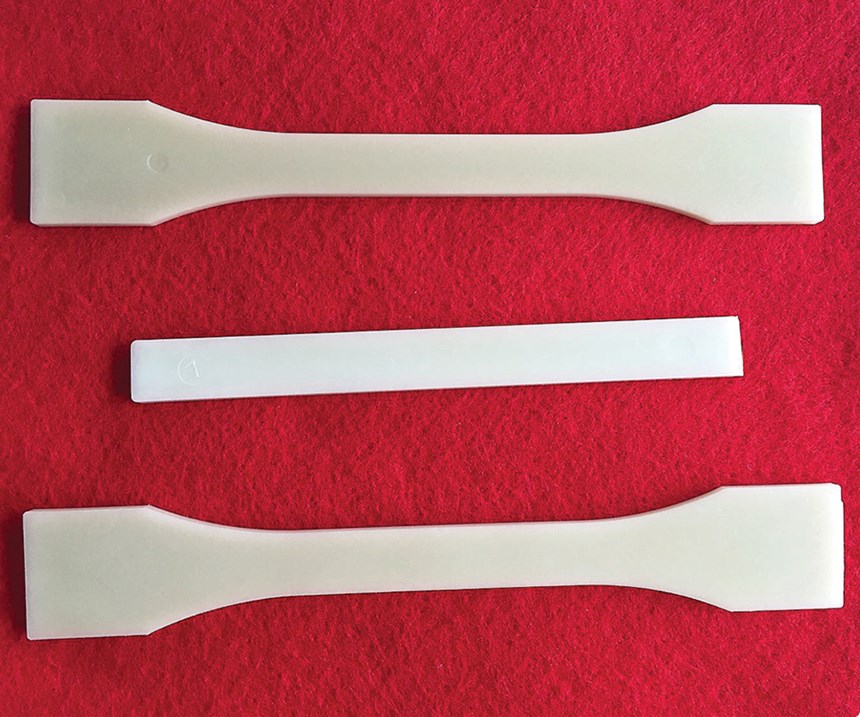

Meanwhile, by varying the base PVDF resin’s molecular structure through either reaction control or copolymerization with another monomer such as hexafluoropropylene (HFP), many standard physical and mechanical properties can be tailored, as well as further manipulated by varying the glass-fiber percentage, says Seiler. In developing the Kynar UHM series, Arkema evaluated various glass levels to achieve the initial performance targets of increasing flexural modulus, tensile strength, and heat-deflection temperature to over 150 C (302 F).

The basic glass-fiber type and percent loading were selected after a battery of testing. The glass type highly influences the chemical-resistance retention in very harsh chemicals often associated with PVDF use. At a high enough concentration, the glass can become a limiting factor in the chemical service rating. The percent loading of the glass fibers is a major influence on how much the mechanical properties are increased in comparison to the neat resin, according to Saeid Zerafati, principal scientist for fluoropolymers at Arkema,

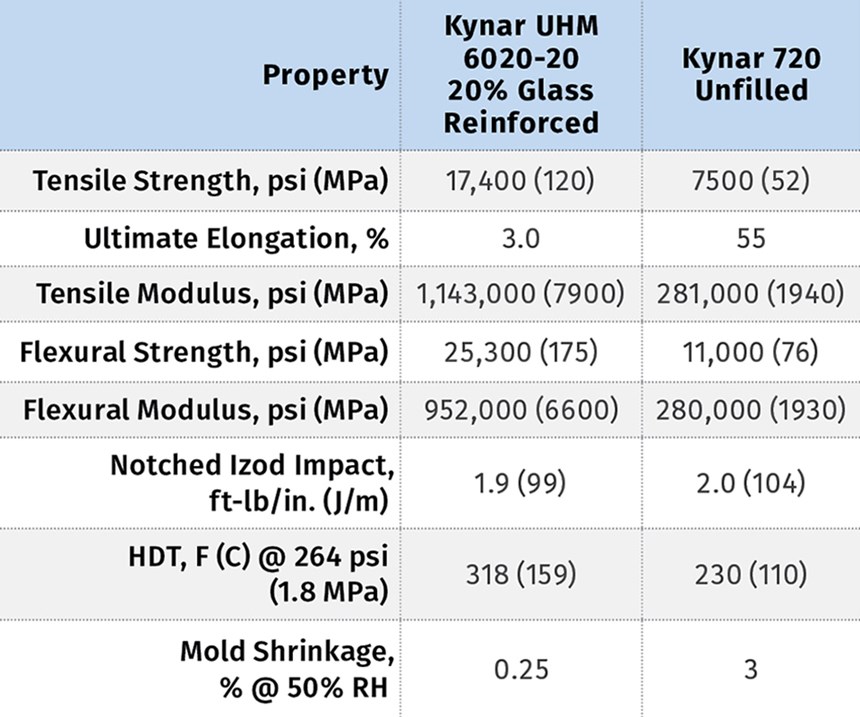

Kynar UHM 6020-20 PVDF composite, which became the baseline for the new series, was shown to significantly outperform all-purpose molding and extrusion homopolymer Kynar 720 in the targeted properties (see table). Zerafati points out that by varying the loading percentage of glass, these numbers can be increased or reduced with a change in ductility. Increased ductility can also be achieved by adding glass to a PVDF of higher molecular weight or a PVDF copolymer such as one made from vinylidene fluoride and hexafluoropropylene.

IMPRESSIVE FLAME RESISTANCE

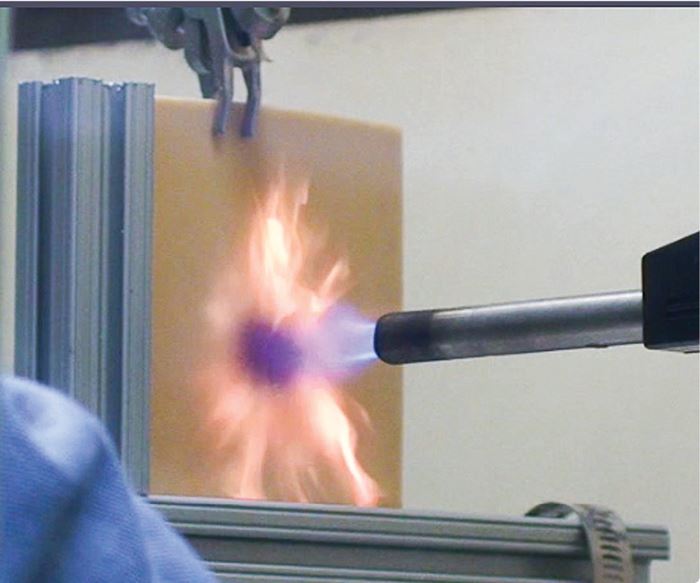

PVDF/glass combinations tested in the past have shown unique performance in flame burn-through resistance. With this in mind, Arkema researchers conducted tests using a propane torch and 1/8-in. thick plaques made from aluminum, glass-fiber mat, PVDF homopolymer, and a Kynar UHM PVDF homopolymer compound with glass fiber. The torch was held 2 in. from a secured plaque of each of the four materials and the time to burn through to the other side of the sample was recorded.

According to Seiler, burn-through results proved very interesting: 85 sec for the aluminum; 3 sec for the glass mat; 28 sec for the unfilled PVDF homopolymer; and 430 sec for the Kynar UHM PVDF with less than 20% glass fiber. Moreover, samples of glass-reinforced PVDF made just a bit thicker (¼ in.) withstood the torch flame for over 15 min without burning through the sample, showing that as this reinforced compound becomes thicker, its resistance to flame becomes greater. While not measured, it was apparent that it took a long time for heat to transfer to the back side of the plaque being burned in the test, according to Seiler. He notes that this effect has been shown in earlier published works on PVDF foams with glass mats.

Related Content

ICIS Launches: Ask ICIS Generative AI Commodities Assistant

Said to be the first of its kind, this AI assistant will enhance access to ICIS’ intelligence and insights for the energy and chemical markets.

Read MorePrices for All Volume Resins Head Down at End of 2023

Flat-to-downward trajectory for at least this month.

Read MoreNPE2024 Materials: Spotlight on Sustainability with Performance

Across the show, sustainability ruled in new materials technology, from polyolefins and engineering resins to biobased materials.

Read MorePrices Bottom Out for Volume Resins?

Flat-to-down trajectory underway for fourth quarter for commodity resins.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More