High-Precision Thermoforming: It's Putting the Pressure in Injection Molding

A look at the production of a high-tech medical device shows why pressure forming has injection molders looking over their shoulders. Complex shapes, undercuts, snap-fits, precise styling lines—all of these are within the capabilities of today’s industrial thermoformers.

Manufacturers of high-precision, highly styled parts that have historically looked to injection molding have a new option that offers equivalent results with shorter lead times and lower tooling costs. Industrial thermoforming is emerging as a competitor for injection molding, providing the complex geometries and tight tolerances that once were the exclusive domain of injection molders.

For high-volume production of small to medium-size parts, injection molding is still more economical and remains the dominant plastics manufacturing process. But for low-volume production of larger parts, industrial thermoforming—particularly pressure forming—has emerged as an attractive alternative. A multi-component enclosure for a medical diagnostic machine is the latest example of how far industrial thermoforming has come in recent years.

Better fit and function

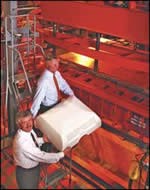

The Skylight Gamma Camera medical-imaging system from Philips Medical Systems, Milpitas, Calif., is the first gantry-free imaging system. The open-floor design permits imaging of a patient in any position, in any bed, and imaging two patients simultaneously. Its thermoformed enclosure panels comprise 20 parts ranging in size up to 30 in. square with draws up to 9 in. deep.

The high-tech unit is complemented by the aesthetics of the newly designed enclosure, which is highly stylized with rounded edges and sleek lines. The original housing was a painted thermoset fiberglass composite. Reasons for switching to pressure forming were better part-to-part consistency and higher output, says Jack Schrieffer, engineering manager for Specialty Manufacturing Inc., a custom thermoformer in San Diego.

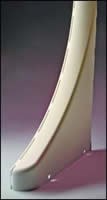

According to Schrieffer, the use of air pressure is critical in attaining precision and appearance that rivals injection molding. Vacuum forming of industrial parts is usually done over a male tool, which controls the inside surface of the part and usually has large radii. Pressure forming, however, typically occurs in a female tool, which controls the outside or appearance surface of the part and can achieve tight radii down to 0.005 in. Such tight radii permit more detailed geometries. In addition, in-mold texturing is possible with female tools.

This thermoforming project was a little more complex than usual. The enclosure panels were redesigned with precise tongue-and-groove, snap-fit connections to simplify assembly. The snap-fits are so effective that only 16 fasteners are used to secure the enclosure. The tabs and receiving slots of the connections are formed into the panels, maintaining tolerances within 0.015 in. (0.51 mm).

Schrieffer says pressure forming readily allows the use of undercuts, which are critical to the tongue-and-groove design. Injection molding tools require costly collapsible cores to achieve the same result.

For Specialty Manufacturing, lead times can be as short as four to six weeks and tooling costs for some large parts can be as much as 75% less than for injection molds.

Sheet ‘memory’ is critical

Integrity of the tongue-and-groove connections also relies on the “memory” of the thermoplastic sheet to maintain the shape of the part after the tabs and slots engage. The parts are made of Kydex T, a high-impact, fire-rated acrylic/PVC sheet from Kleerdex Co. “A key to the design is the natural memory of the thermoplastic sheet in achieving a snap-fit,” explains Schrieffer. The material provides a good balance of stiffness and elasticity. Notched Izod impact resistance of 15 ft-lb/in. is significantly better than many competing materials for protection against contact with wheelchairs and gurneys. The material also carries a UL 94V-0/5V fire rating. Sheet thicknesses range from 0.187 to 0.250 in. (4.8 to 6.4 mm).

Because the medical diagnostic unit is produced in limited quantities, typically in the hundreds per year, color consistency is also a special concern. Philips Medical must be able to mix and match components as necessary whether for new units or as replacement parts, with no variation in color. “The material is color-matched to offer the repeatability that is associated with a precision color house,” says Schrieffer.

Specialty Manufacturing uses a custom four-station rotary pressure former from Maac Corp. The processor opted for a counterpressure floating platen instead of a typical mechanical-lock type. The platen maintains constant pressure, resulting in consistent forming shot-to shot and run-to run, says Schrieffer. Forming-air pressure is applied at 80 psi over the entire platen surface up to 5 x 8 ft. The platen has a deflection of no more than 0.005 in.

Specialty Manufacturing has 50 employees and nine forming machines. The company also does twin-sheet forming and thin-gauge medical packaging.

Tooling and trimming

The tooling, manufactured in-house by Specialty Manufacturing, consists of temperature-controlled, machined aluminum. Schrieffer notes that part appearance hinges on the ability of the sheet to accurately reproduce the acid-etched texture of the aluminum molds. The sheet reproduces mold finish accurately, with no part-to part variation, even among deep-drawn parts. Mold texturing was done by Pacific Texture in Riverside, Calif.

Another essential element of producing tight-tolerance formed parts with high aesthetic requirements today is use of multi-axis CNC trimming equipment. Schieffer notes that a design change can often be accomplished by a simple programming revision such as adjusting the height of a cut or dimension of an opening. “This makes pressure forming even more attractive than injection molding from an overall cost and time-to-market viewpoint,” he says.

Related Content

ExxonMobil Develops High-Performance, 95% PE Recyclable Thermoformed Packaging

The packaging solution involved a collaboration with equipment suppliers Hosokawa Alpine and Multivac Group.

Read MoreWinners Announced for SPE Thermoforming 2023 Parts Competition

More than 30 entries were considered, including 10 in the Sustainability category.

Read MoreOMV Technologies Gets New CEO

Kooper brings 33 years of experience in the industrial and consumer packaging industries to OMV--the closed-loop, turnkey, inline extrusion, thermoforming and tooling systems manufacturer.

Read MoreThermoformed Container Keeps Battery Cells Safe

Despite last-minute design changes and other unexpected roadblocks, thermoformer TriEnda works with a key supplier on innovative reusable shipping container.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More